Device for enabling concrete member to resist shear and be reinforced by bonding plates and construction method

A construction method and concrete technology, which is applied in building construction, building maintenance, construction, etc., can solve problems such as poor bonding effect, difficulty in fixing reinforced plates, and low bonding flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

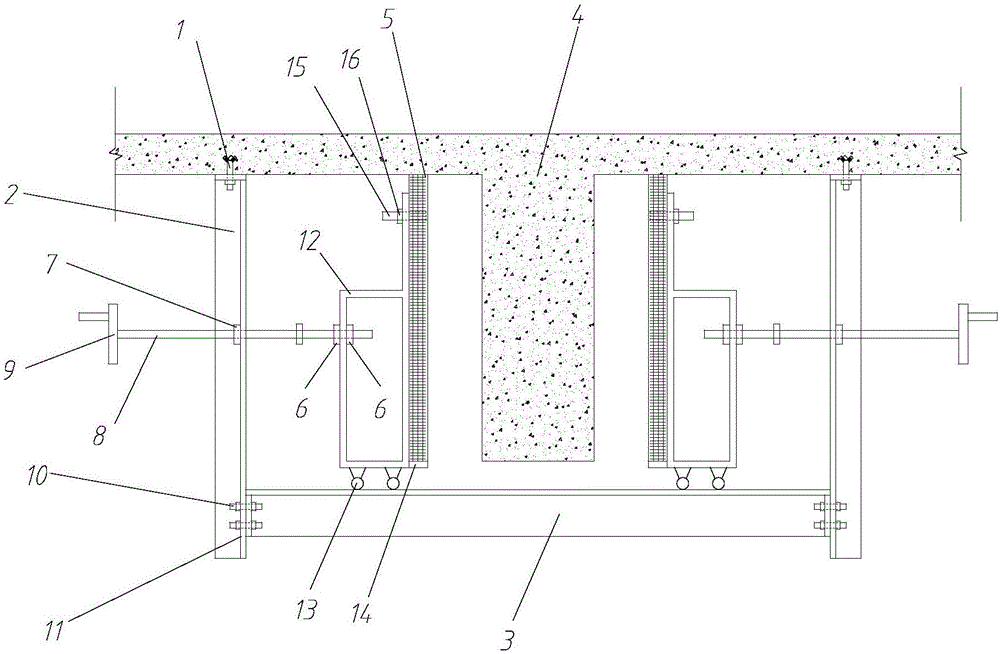

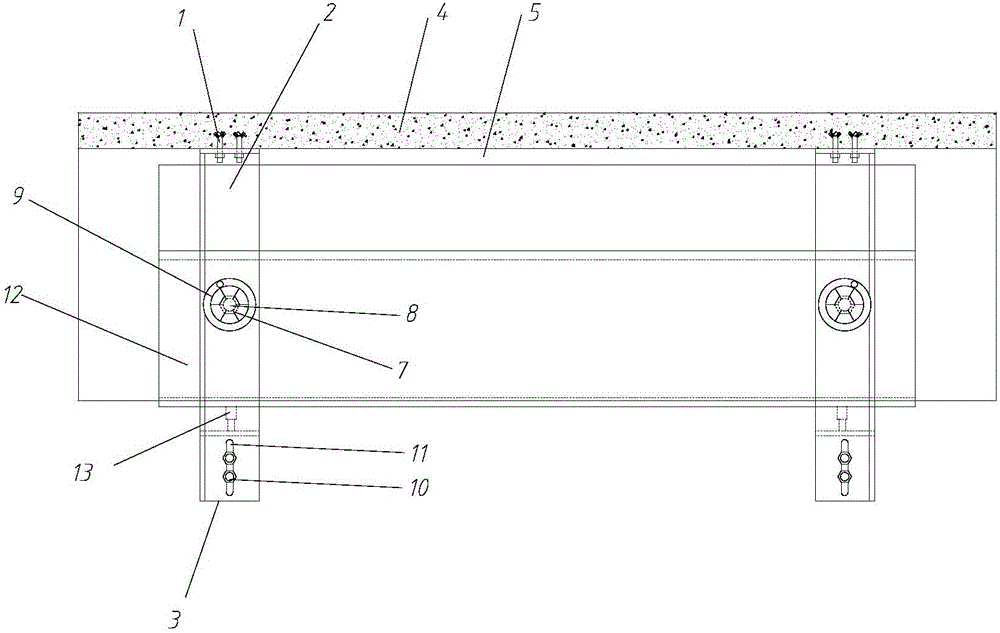

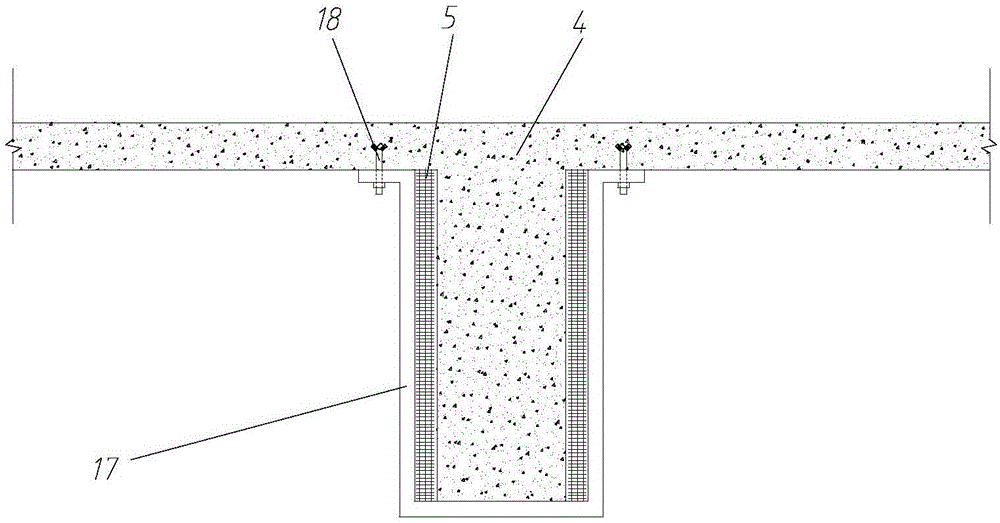

[0026] The present invention will be further described in detail below in combination with specific implementation methods and accompanying drawings.

[0027] The first step is to install the vertical support of the equipment on the concrete shear member, and drive the expansion bolts of the vertical support into the concrete at the bottom of both sides of the cast-in-place concrete beam, and fix the vertical support.

[0028] The second step is to install the bottom bracket of the device and connect the device bracket into a whole.

[0029] The third step is to weld the fixing nut and the vertical support, pass the shaft head of the roller bearing through the fixing nut, and then connect with the handle through bolts. Place the plate fixing device with rolling pulleys on the bottom bracket of the equipment, connect the roller bearings with the sleeve, and insert the other end of the screw into the bolt hole of the propulsion platform, and connect with the fixing bolts. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com