Novel gearbox capable of transmitting large torque

A gearbox and high-torque technology, which is applied in the field of new gearboxes, can solve problems such as the inability to operate work tools, the steel belt is easy to slip, and the inability to transmit large torques, etc., achieving high practical value and promotion value, and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

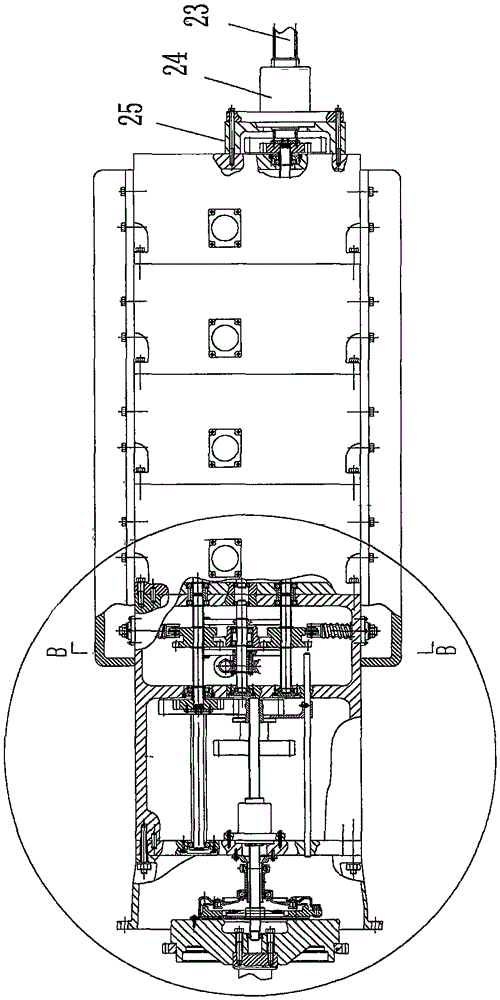

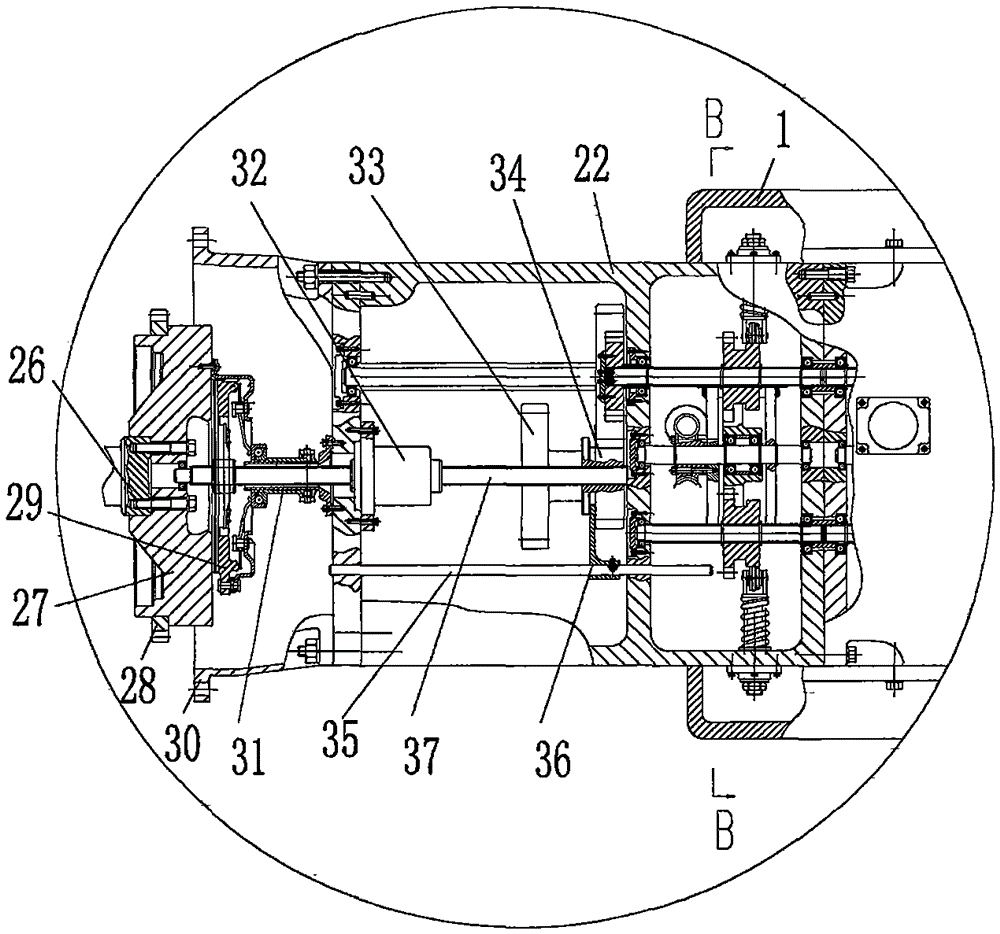

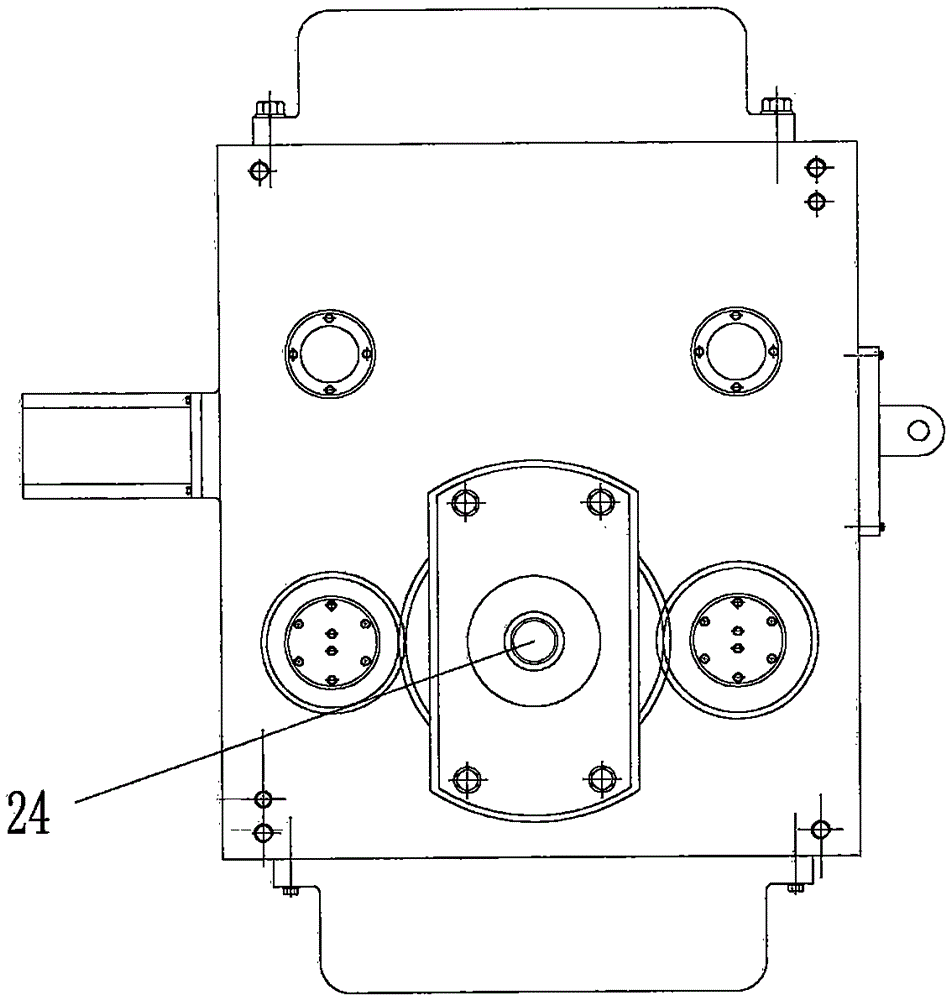

[0019] as attached Figure 1-7The shown novel gearbox of the present invention that can transmit high torque includes a box body 1, a power output shaft 23, a first bracket 25, an output shaft speed and torque sensor 24, a servo motor 3, a transmission mechanism, a first A box 22, connecting box 30, engine crankshaft 26, input shaft 37, engine flywheel 27, flywheel ring gear 28, clutch assembly 29, clutch separation mechanism 31, input shaft speed and torque sensor 32, exchange gear 34, reverse gear 33, shift fork shaft 35 and shift fork 36; said casing 1 side is provided with power output shaft 23; said power output shaft 23 is provided with output shaft speed and torque sensor 24 on the first bracket 25 ; The box 1 is provided with five servo motors 3 arranged in sequence; the servo motor 3 is connected to the corresponding transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com