Method for using a fastening device of an instrument working condition detection system

A detection system and fastening device technology, applied in the direction of supporting machines, mechanical equipment, etc., can solve the problems of camera looseness, time-consuming and physical strength, corrosion and other problems, achieve rapid disassembly and installation, improve service life, and increase detection range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

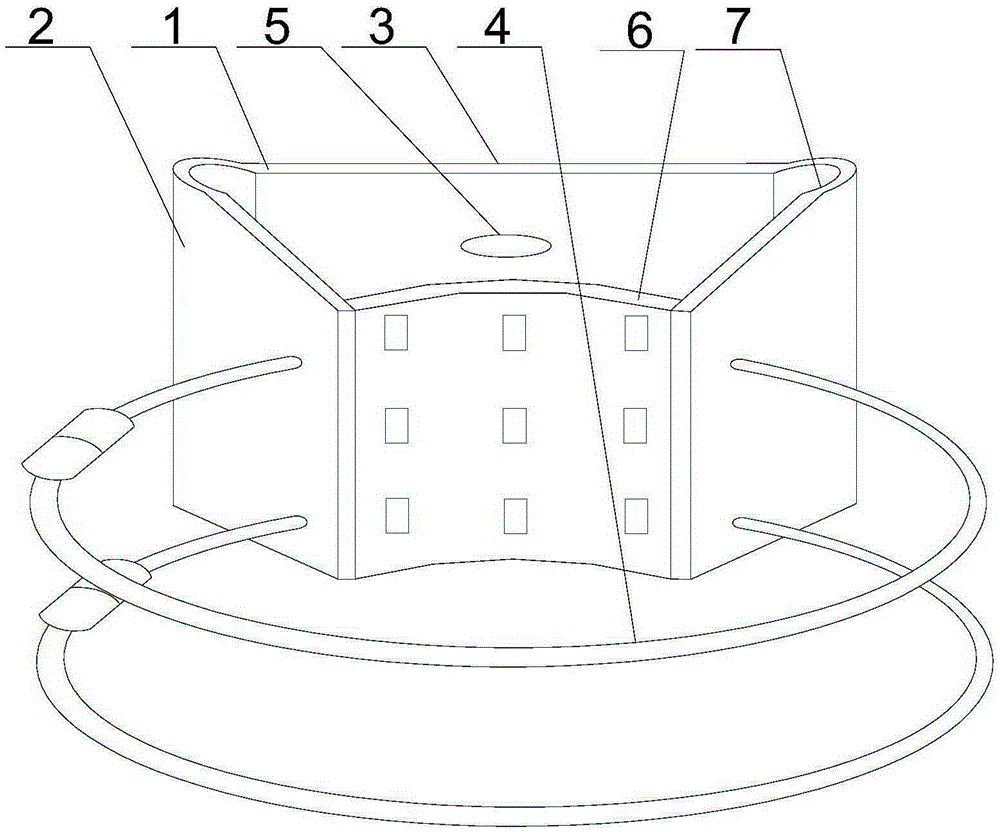

[0025] Such as figure 1 Shown, the present invention comprises the following steps:

[0026] A First place the ends of the two fixed plates on the rod-shaped support structure;

[0027] B Then fasten the dovetail-shaped mounting seat formed by the two fixed plates and the bottom plate on the outer peripheral wall of the dry support structure through the clamp;

[0028] C The adjustment plate can contact the outer circumferential wall of the support structure before the fixed plate contacts the outer circumferential wall of the support structure, so as to realize the flexible connection between the mounting seat and the support structure. When the monitoring equipment is shaken by external force, the elastic adjustment The plate can eliminate the generated stress through its own certain deformation and deformation recovery;

[0029] D When installing, the tension pad is directly attached to the outer peripheral wall of the support structure, and the multiple small holes opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com