Temperature Probes and Extruders

A technology of temperature probe and extruder, applied in the field of temperature probe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

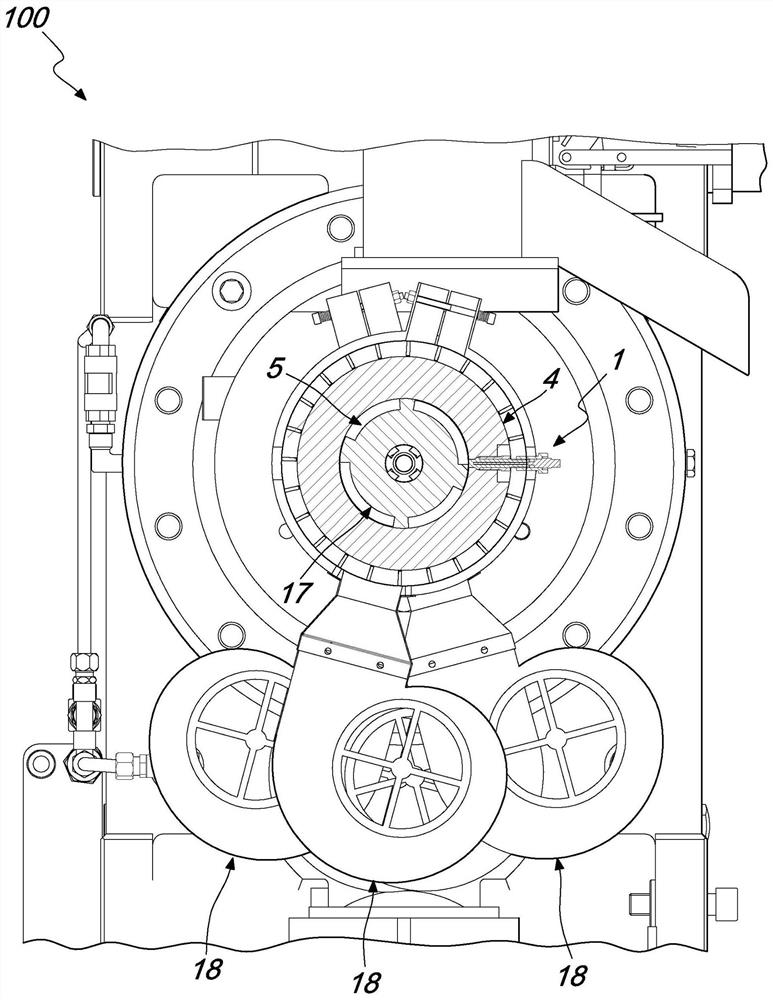

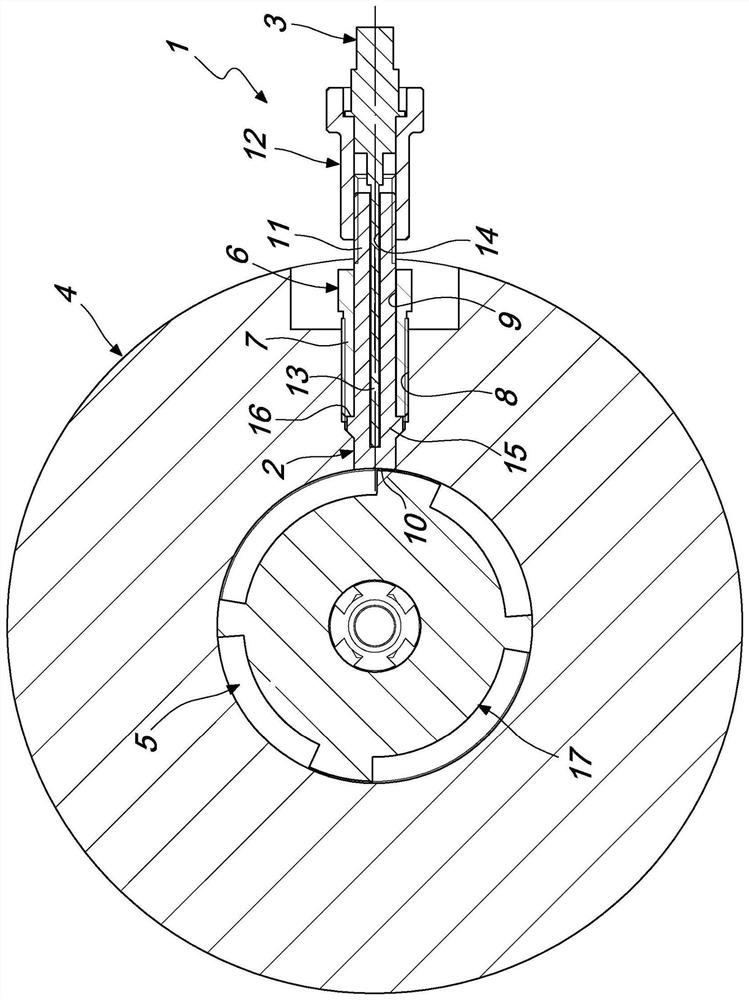

[0022] With reference to these figures, the temperature probe, in particular for thermoplastic compound extruders, generally indicated with reference numeral 1 , comprises at least one housing 2 and at least one thermocouple 3 accommodated inside the housing 2 .

[0023] As will be better described hereinafter, the housing 2 is adapted to be inserted into the extrusion cylinder 4 substantially at right angles to the direction of extrusion, with one end facing into the inner cavity 5 of the extrusion cylinder 4, so that the housing and the The extruded material in cavity 5 is in direct contact.

[0024] Consider a thermocouple 3 adapted to detect the temperature of the extruded material circulating in the cavity 5 by heat conduction through the housing 2 .

[0025] According to the invention, thermal insulation 6 is included at least partially between housing 2 and extrusion cylinder 4 in order to reduce the thermal influence of the latter on the measurements made by thermocoup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com