Cladding system of fusion-fission reactor

A reactor and cladding technology, applied in the field of cladding systems of fusion fission reactors, can solve the problems of difficulty in large-scale deployment, difficulty in mixing reactors, poor economy, etc., and achieve the advantages of improving tritium production efficiency, reducing assembly difficulty, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

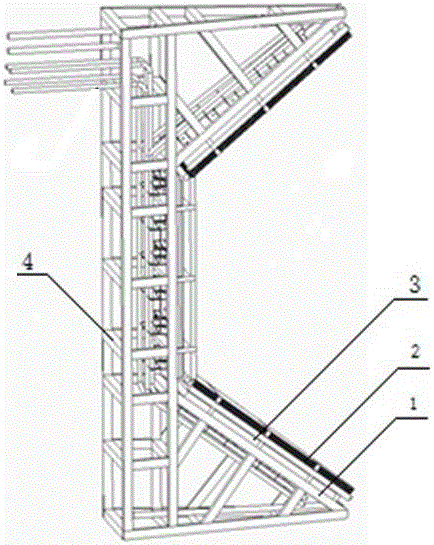

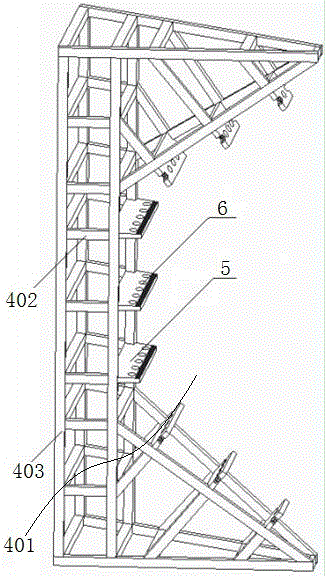

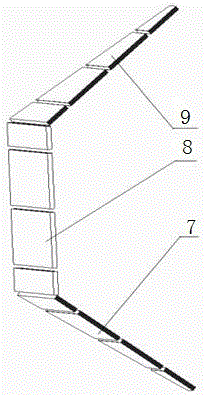

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 The cladding system of the fusion and fission reactor shown includes: 18 cladding modules, which are spliced and wrapped in the fusion target chamber to form a 360° cladding system, and each cladding module includes several connected tritium-producing Module 1, several connected fuel modules 2 and support device 4, the top of the cladding system is provided with an opening for installing a fusion load, and the bottom is provided with an opening for installing a core residual tritium recovery system, and the support device 4 has Facing the inner recess 401 in the center of the fusion target chamber, the cross-sectional shape of the cladding system along the longitudinal axis is hexagonal, and the hexagon is symmetrical along the longitudina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com