High-voltage coil structure of resin-cast dry-type transformer, winding method and transformer

A dry-type transformer and high-voltage coil technology, applied in the field of transformers, can solve the problems of excessive discharge of products, increased discharge of coils, and low work efficiency, and achieve the effects of small partial discharge, low voltage between cakes, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0037] The current high-voltage coil structure of cast resin dry-type transformers has been using multi-segment multi-layer cylindrical coil structures for a long time, and corresponding technical prejudices have been formed for a long time, which has greatly affected the development of cast resin dry-type transformers.

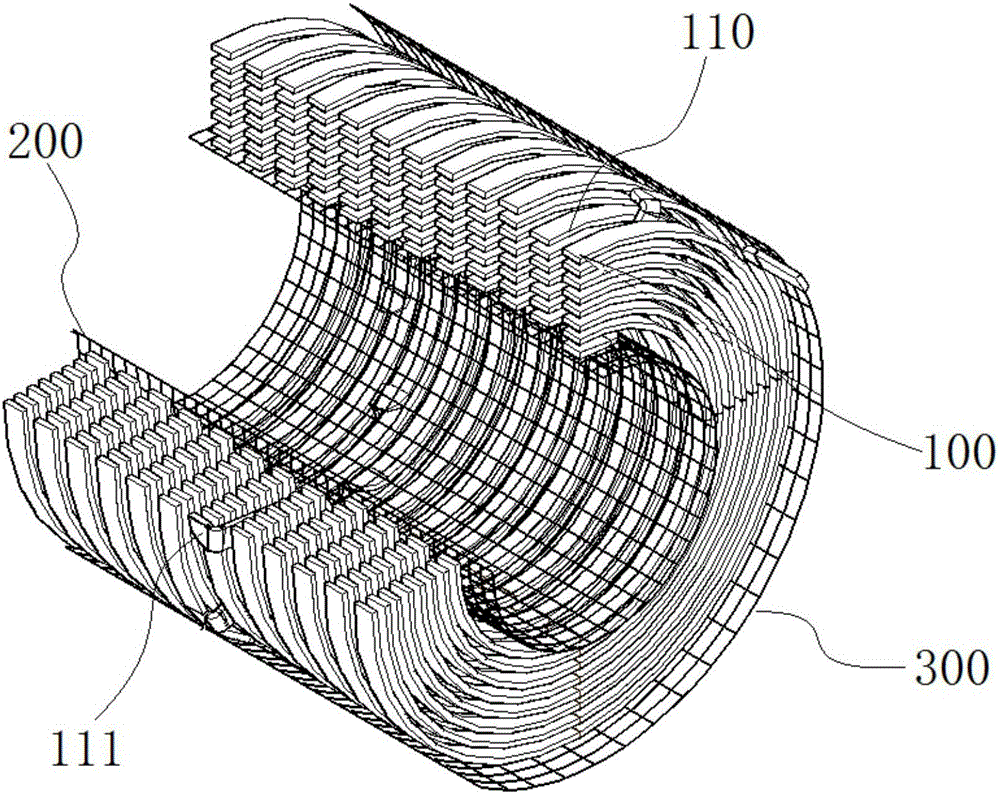

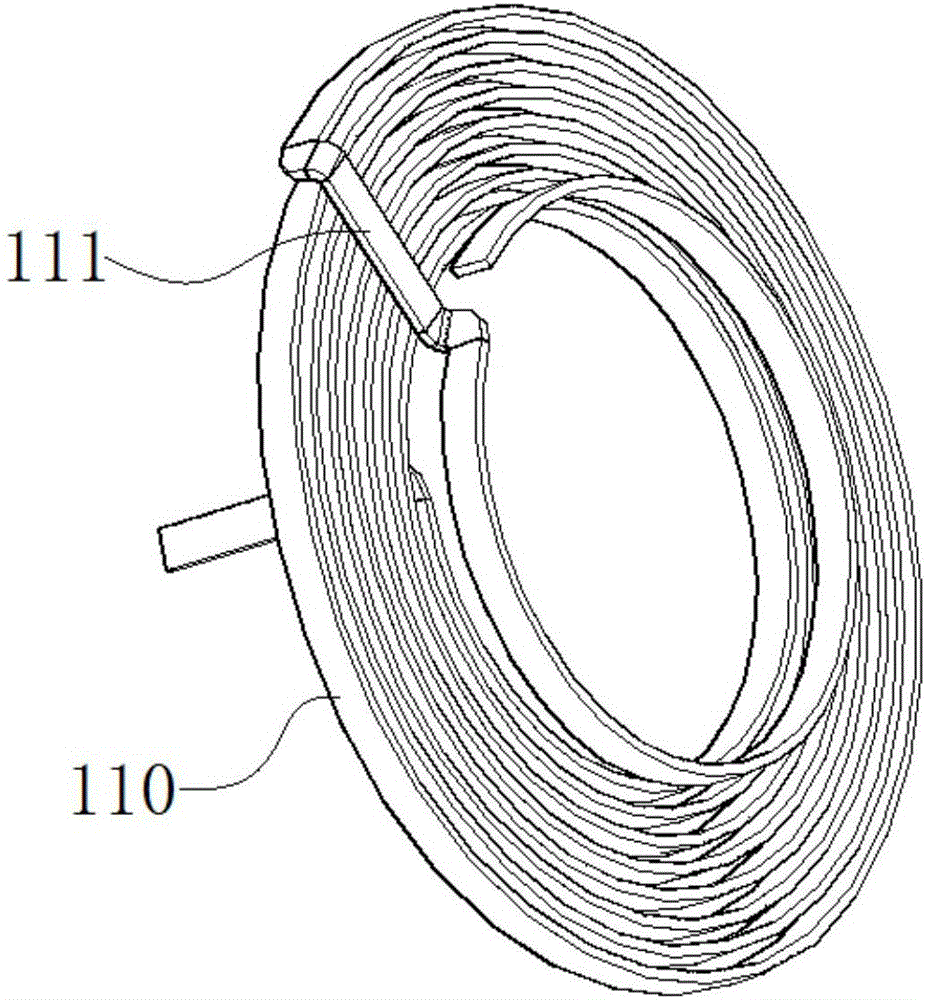

[0038] This example abandons the existing multi-segment multi-layer cylindrical coil structure scheme and innovatively adopts a pie-shaped coil structure. However, this pie-shaped coil structure does not use the conventional winding method of positive and negative cakes, but uses a winding of both positive and negative cakes. Method composition. That is to say, in the pie coil structure, each layer of wire cake starts from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com