Induction cooker continuous low power control circuit and control method

A control circuit, low-power technology, applied in the field of induction cooker, can solve the problems of water rolling and stop, can not provide low-power stability, etc., to achieve the effect of continuous stable power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

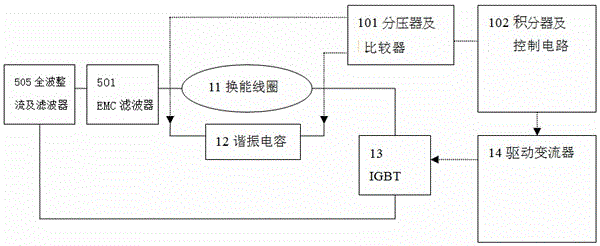

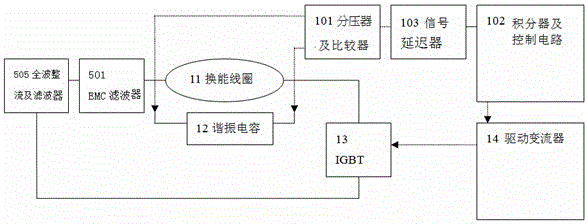

[0028] figure 1 It is a schematic diagram of the structure of the electromagnetic heating device of the present invention. The electromagnetic heating device adopts a structure in which the transduction coil is driven by high-frequency pulse width modulation energy and the iron low magnetic resistance cooking vessel is combined. The transduction coil 11 is composed of a resonant capacitor 12 One end of the LC resonant circuit is connected to the full-wave rectifier and filter 505 , and the other end is connected to form a loop through the IGBT 13 . The full-wave rectification and filter 505 provides a solution to make the circuit regard each positive and negative cycle of the mains power supply as two positive cycles, which are connected to one end of the LC resonant circuit, which is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com