Gear driving buckle type high-heeled shoe with replaceable heel

A gear-driven, snap-on technology, applied in footwear, heels, heel pads and other directions, can solve the problems of increasing the sole accommodation space, complicating the processing technology, and affecting the strength, so as to achieve the simple and fast removal and replacement of high-heeled shoes. The appearance is smooth and beautiful, and the effect of ensuring thickness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

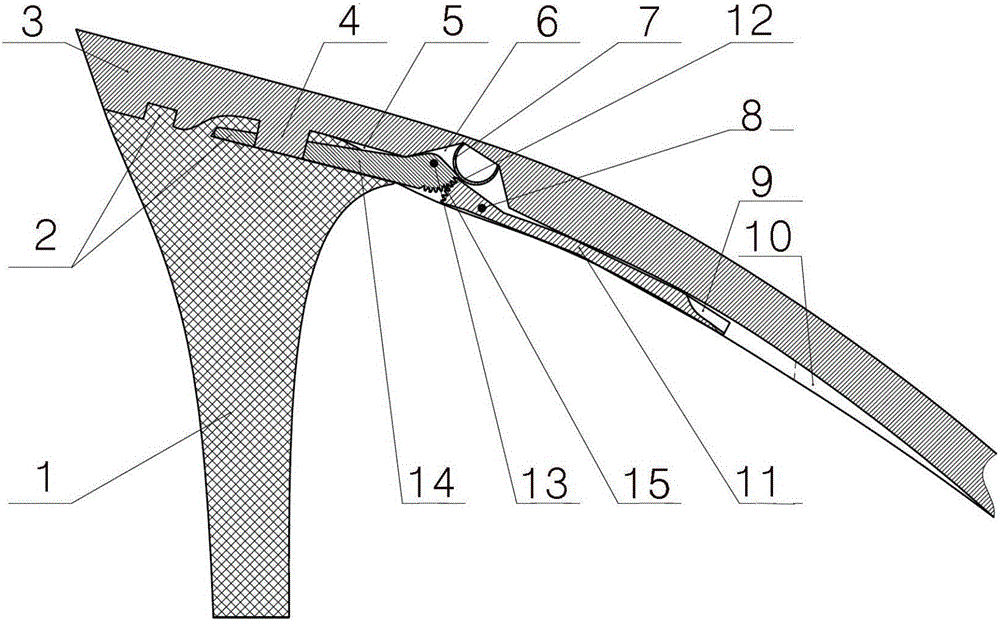

[0032] Example 1: figure 1 It is a schematic diagram of the overall structure of Embodiment 1 of the present invention, a high-heeled shoe with a buckle 14 type, including a sole 3 and a heel 1, the sole 3 is provided with a gear-driven buckle 14 heel-off device, and the gear-driven buckle 14 is heel-off The device comprises a buckle 14 and a pull rod 11 that are pivotally connected to the shoe sole 3 holder 10, the buckle 14 is connected to the holder 10 through a first fixed shaft 8, and the pull rod 11 is connected to the holder 10 through a second fixed shaft 13. The radian of the lower surface of the sole 3 fits, and one end of the buckle 14 is inserted into the groove of the heel protrusion 2, and the other end is provided with a buckle part gear, and the buckle part gear 12 is connected to the pull rod part gear 15 at one end of the pull rod 11. Teething of the number of teeth, the upper part of the meshing part of the buckle part gear 12 and the pull rod part gear 15 i...

Embodiment 2

[0034] Embodiment 2: A buckle 14 style replaceable high-heeled high-heeled shoes, including a sole 3 and a heel 1, the sole 3 is provided with a gear-driven buckle 14 heel-off device, and a lifting ring is used to replace the pull rod notch 9, and a Y-shaped The compressed spring piece replaces the arc-shaped elastic piece, and the pulling rod 11 is driven to move by pulling the ring. The through hole on the buckle 14 is replaced by a groove, and the limit fixing block 4 is inserted into this groove. The buckle 14 and the pull ring are directly fixed on the sole 3, between the groove 5 of the sole and the 2 heel protrusions, between the protrusion 3 of the sole and the groove of the heel 1, and between the limit fixing block 4 and the heel 1 1. There is a small gap in the contact part between the limit fixing block 4 and the buckle 14, so that the sole 3 and the heel 1 are accurately docked to avoid moving back and forth or falling. The thickness of the sole 3 is 15mm, and the ...

Embodiment 3

[0035] Embodiment 3: A gear-driven buckle 14 style replaceable high-heeled shoes, including a sole 3 and a heel 1, the sole 3 is provided with a gear-driven buckle 14 heel-off device, and the buckle 14 is not inserted into the heel 1 Both the part and the tie rod 11 are embedded in the sole 3, and the notch 9 of the tie rod is also hidden inside the sole 3, leaving a notch for fingers to enter. The angle of rotation of the buckle 14 axis is less than or equal to 60 degrees, and the thickness of the sole 3 is 30mm , The material of the heel 1 is carbon fiber, the material of the shaft connecting the buckle 14 and the pull rod 11 on the connecting frame 10 is also carbon fiber, and the rest of the technical features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com