Portable welding flue gas purifying device and purifying method

A welding fume and purification device technology, which is applied to chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as injury, air pollution, and welding fume that cannot be effectively purified, so as to improve the filtering effect and purify The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

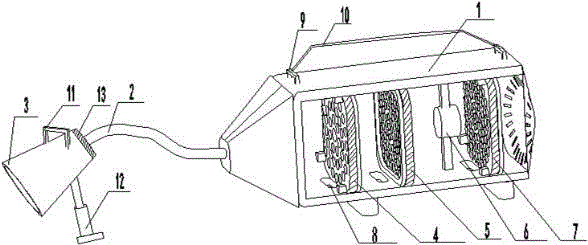

[0016] A portable welding fume purification device, which consists of: a device housing 1, the front end of the device housing is connected to the end of the suction pipe 2, the front end of the suction pipe is connected to the drainage hood 3, the device housing Coarse filter cotton 4, fine filter cotton 5, blower fan 6, and activated carbon adsorption cotton 7 are installed in sequence in the interior, a settling tank 8 is installed at the bottom of the device housing, and a handle 9 is installed at the top of the device housing. The handle is connected with a strap 10 .

Embodiment 2

[0018] According to the portable welding fume purification device described in Embodiment 1, a hanging ring 11 is installed on the top of the draft hood, a support frame 12 is installed on the bottom of the draft hood, and a flame-proof net is installed at the inner end of the draft hood 13. The suction pipe is a high temperature resistant flexible pipe; the number of the settling tanks is three; the number of the handles is two.

Embodiment 3

[0020] A purification method using the portable welding fume purification device described in Embodiment 1 or 2, the fume generated during the welding process is passed into the device housing through the drainage hood and the suction pipe under the negative pressure of the fan, with The large particles of Mars are blocked by the flame-proof net to protect the suction pipe. The welding smoke passes through the coarse filter cotton, and the particles with larger diameters are caught by the coarse filter cotton. The particles gather under the action of gravity and fall into the sedimentation tank. The escaped small particles collide with the fine filter cotton, are intercepted by the surface of the fine filter cotton, and finally fall into the settling tank. The harmful fume is finally absorbed by the activated carbon adsorption cotton, and the welding fume after adsorption is discharged into the air. This process realizes Multi-stage dust removal and filtration of welding fume, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com