Powdered food mixing equipment

A food and powder technology, applied in the field of powder food mixing equipment, can solve the problems of flying powder, poor sanitation, and large labor, and achieve the effect of ensuring the uniformity of stirring and avoiding the scattering of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

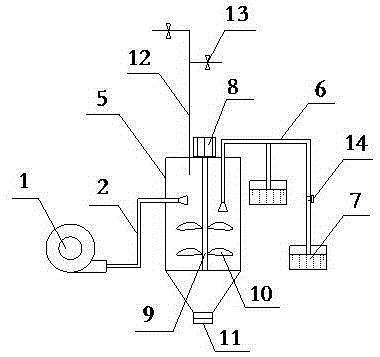

[0012] Such as figure 1 As shown, the powdery food mixing equipment of the present embodiment, the powdery food mixing equipment comprises a vacuum pump 1, an agitator 5 and a storage tank 7, and a plurality of storage tanks 7 pass through the feeding pipe 6 and the agitator 5 The middle and lower parts of the cavity communicate, and the vacuum pump 1 communicates with the middle and upper part of the inner cavity of the agitator 5 through the exhaust pipe 2; the upper part of the agitator 5 is provided with a liquid pipeline 12, and the lower part is provided with a discharge port 11; The motor 8 on the top of the feed tank 5, the output shaft of the motor 8 is connected to the rotating shaft 9, the rotating shaft 9 is provided with blades 10, the exhaust pipe 2 and the port of the feeding pipe 6 in the agitator 5 are provided with The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com