A kind of copper cerium co-doped magnetic composite material and its preparation and application method

A magnetic composite material and co-doping technology, applied in chemical instruments and methods, other chemical processes, oxidized water/sewage treatment, etc., can solve the problem of weakening As(III) adsorption and removal, difficulty in realizing oxidation transformation, and no adsorption Characteristics and other issues, to achieve excellent arsenic adsorption effect, excellent arsenic adsorption performance, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of copper-doped magnetic composite material:

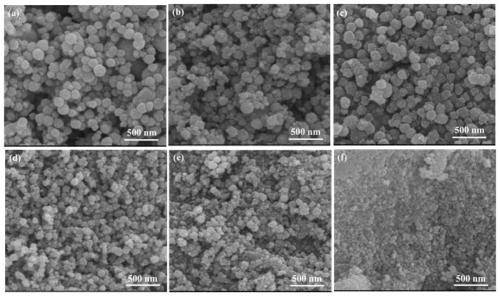

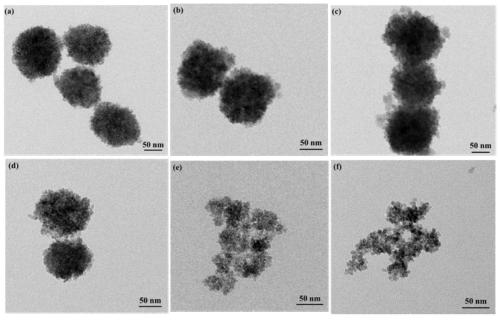

[0030] 1.35g FeCl 3 ·6H 2 O, with 0.427g CuCl 2 2H 2 O Add 36mL of ethylene glycol solution, ultrasonically dissolve the solid metal salt, mix evenly, then add 3.6g of anhydrous sodium acetate, stir vigorously for 30min, then transfer to an autoclave at 200°C for 6h; after cooling to room temperature, magnetic Separate, wash, and dry at 60°C for 6 hours to obtain a copper-doped magnetic composite material. The resulting product was characterized by SEM and TEM, see respectively figure 1 (a) and figure 2 (a).

Embodiment 2

[0032] 1.35g FeCl 3 ·6H 2 O, 0.427g CuCl 2 2H 2 O with 0.093g CeCl 3 ·7H 2 0. Add 36mL ethylene glycol solution, ultrasonically dissolve the solid metal salt, mix evenly (the initial copper ion to cerium ion molar ratio is 10:1), then add 3.6g anhydrous sodium acetate, stir vigorously for 30min, then turn to React in a high-pressure reactor at 200°C for 6h; cool to room temperature, magnetically separate, wash, and dry at 60°C for 6h to obtain a copper-cerium co-doped magnetic composite material. The resulting product was characterized by SEM and TEM, see respectively figure 1 (b) and figure 2 (b).

Embodiment 3

[0034] 1.35g FeCl 3 ·6H 2 O, 0.427g CuCl 2 2H 2 O with 0.186g CeCl 3 ·7H 20 Add 36mL of ethylene glycol solution, ultrasonically, fully dissolve the metal salt solid, mix evenly (the initial copper ion to cerium ion molar ratio is 5:1), then add 3.6g of anhydrous sodium acetate, stir vigorously for 30min, then turn to React in a high-pressure reactor at 200°C for 6h; cool to room temperature, magnetically separate, wash, and dry at 60°C for 6h to obtain a copper-cerium co-doped magnetic composite material. And carry out SEM and TEM characterization to the product of gained, see respectively figure 1 (c) and figure 2 (c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com