Intelligent centrifuge control method and device in full-automatic cell cultivation system

A cell culture and control method technology, applied in the field of intelligent centrifuge control, can solve the problems of low work efficiency, inability to guarantee the cell culture environment, contamination of the culture medium, etc., and achieve the effects of easy removal, reduction of manpower, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

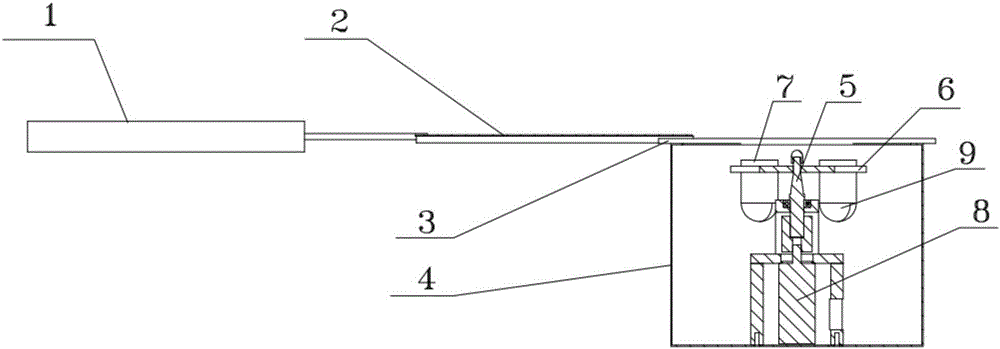

[0020] The invention will be further described below with reference to the accompanying drawings and in combination with specific embodiments, so that those skilled in the art can implement it by referring to the description, and the protection scope of the present invention is not limited to the specific embodiments.

[0021] In the intelligent centrifuge control method in the fully automatic cell culture system, the rotating frame 6 of the centrifuge includes a number of loading frames 7, the number of the loading frames 7 is fixed as N, and the required centrifuge loading frames The number of centrifuge tubes 9 in 7 miles is n, and n≤N, one of the loading frames is set as the initial loading frame, and the position of the initial loading frame is set as the initial point, and the control method includes The following steps:

[0022] (1) The controller controls the relay inside the centrifuge. When the relay is in a high level state, the servo servo motor 8 rotates and drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com