Equipment and process of garbage separation and pyrolysis treatment furnace integral treatment station

A treatment station and treatment furnace technology, applied in lighting and heating equipment, incinerators, solid separation, etc., can solve the problems of economic loss, high cost, pollution of available resources, etc., and achieve the elimination of dioxin production and work performance. Stable and efficient pyrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

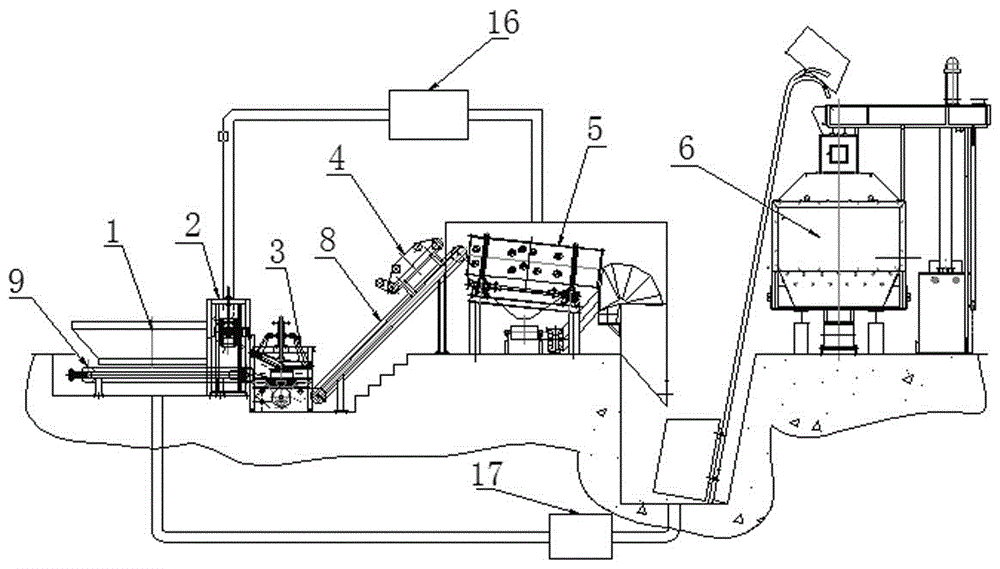

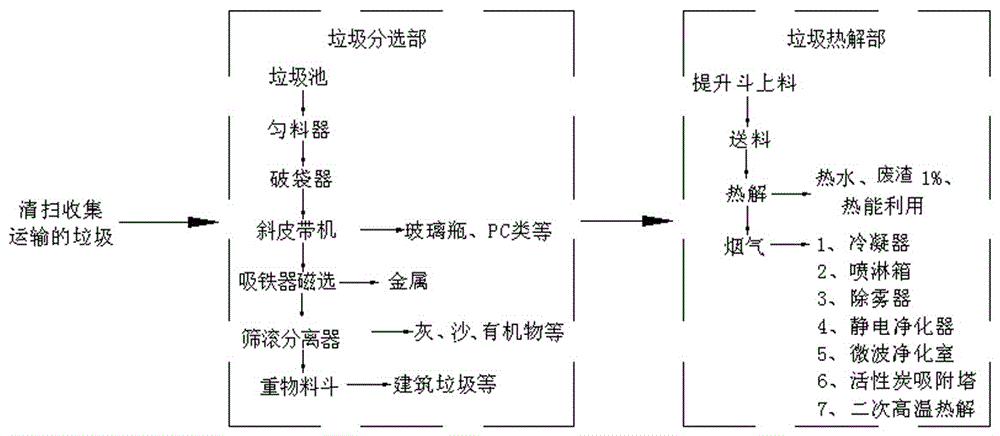

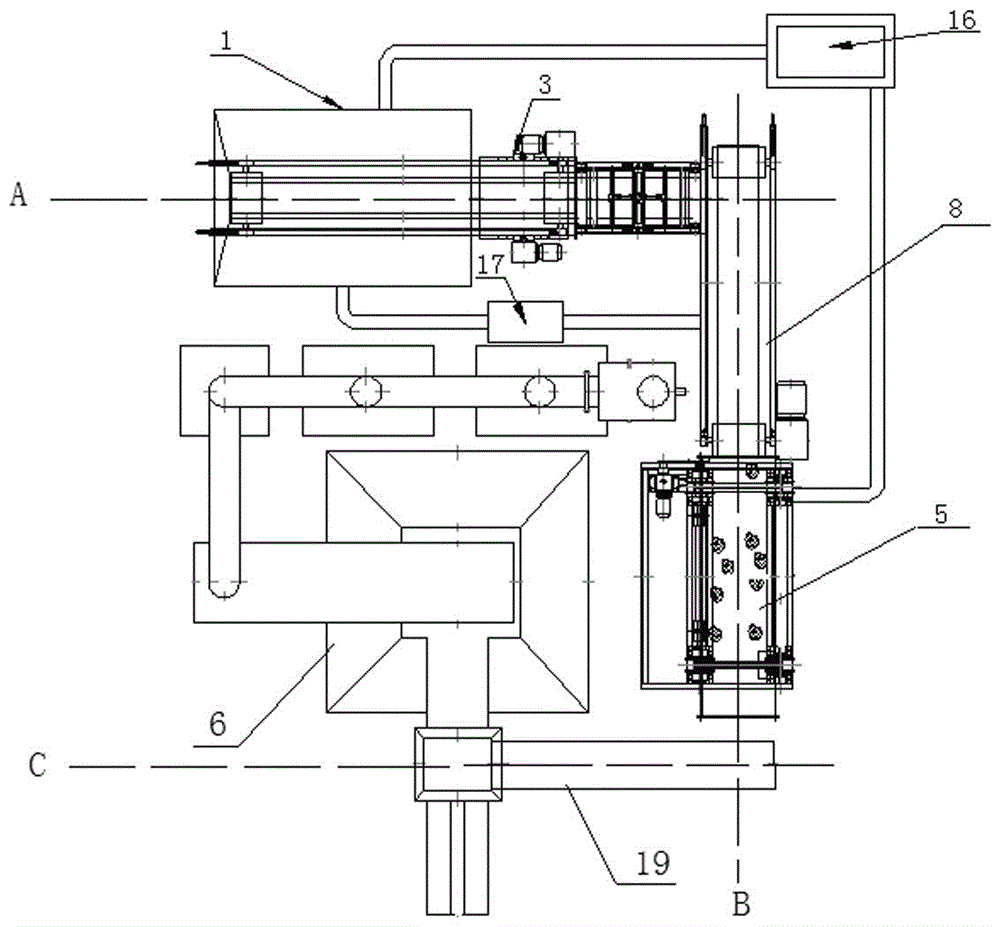

[0038] refer to figure 1, an integrated garbage sorting + pyrolysis treatment furnace integrated treatment equipment, including garbage pool 1, leveler 2, bag breaker 3, iron absorber 4, inclined belt conveyor 8, screen roller separator 5 and pyrolysis Furnace6. A flat belt conveyor 9 is arranged below the outlet of the garbage pool 1, and one end of the flat belt conveyor 9 extends into the homogenizer 2, and the bag breaker 3 is arranged adjacent to the outlet end of the homogenizer 2, and the outlet end of the bag breaker 3 passes through the inclined belt conveyor 8 is connected to the feed inlet of the screen-roll separator 5, and the iron absorber 4 capable of absorbing metal is set on the inclined belt conveyor 8, and a lifting bucket 10 is provided under the screen-roll separator 5, and the lifting bucket 10 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com