Hot rolling device and hot rolling method for TiA alloy plate

An alloy sheet and heating device technology, applied in metal rolling, temperature control and other directions, can solve the problems of temperature drop and operation difficulties, and achieve the effect of improving surface quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

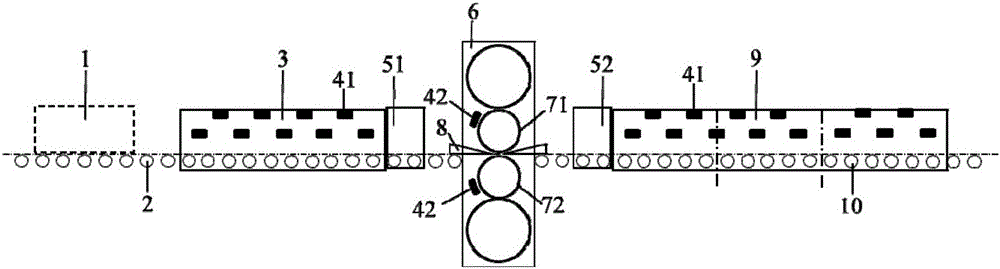

[0048] This embodiment provides a TiAl alloy plate hot rolling device, its structure is as follows figure 1 shown. The device includes a roller table, and the second heating furnace 1, the first heating furnace 3, the heat preservation cover 51 before the rolling mill, the hot rolling mill 6, the heat preservation cover 52 after the rolling mill and the roller hearth tunnel heat treatment furnace 9 arranged in sequence beside the roller table ;

[0049] The roller table includes a furnace inner roller table 10 and an outer furnace roller table 2, wherein the furnace inner roller table 10 includes several roller table groups (each roller table group contains 5 roller tables), wherein each roller table group can be separated Rotation or at least two groups of linkages, each roller table group can rotate forward or reverse, and the rotation speed is 0.6m / min; the roller table 2 outside the furnace before and after the hot rolling mill can rotate independently, and can rotate for...

Embodiment 2

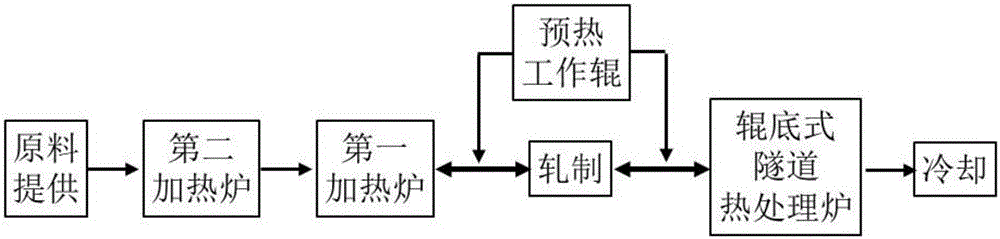

[0059] This embodiment provides a method for hot-rolling TiAl alloy sheets, which is carried out using the device in Embodiment 1, and the specific process is as follows figure 2 shown. The method includes the following steps:

[0060] (1) Supply of raw materials: provide a Ti-43.5Al-4Nb-1Mo-0.1B (at.%) alloy (abbreviation: TNM alloy) slab, and coat the surface of the alloy slab with a high-temperature oxidation-resistant coating;

[0061] (2) Heating: place the TNM alloy slab in the second heating furnace 1, heat it to 1180°C, and transport it into the first heating furnace 3 through the roller table 2 after being released from the furnace, and heat it to 1255°C (the temperature of forward rolling ), keep warm for 30min;

[0062] (3) Preheating work rolls: before the TNM alloy slab leaves the first heating furnace 3, the surface temperature of the upper work roll 71 and the lower work roll 72 of the hot rolling mill 6 is heated to 500 by a continuous online high-frequency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com