Pre-embedded electric heating flow channel

A technology of electric heating and laundering, applied in metal processing equipment, equipment for feeding molten metal into molds, manufacturing tools, etc., can solve the problems of cumbersome operation, affecting normal production, low efficiency, etc., and achieve broad application range, the effect of extending the life of the launder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

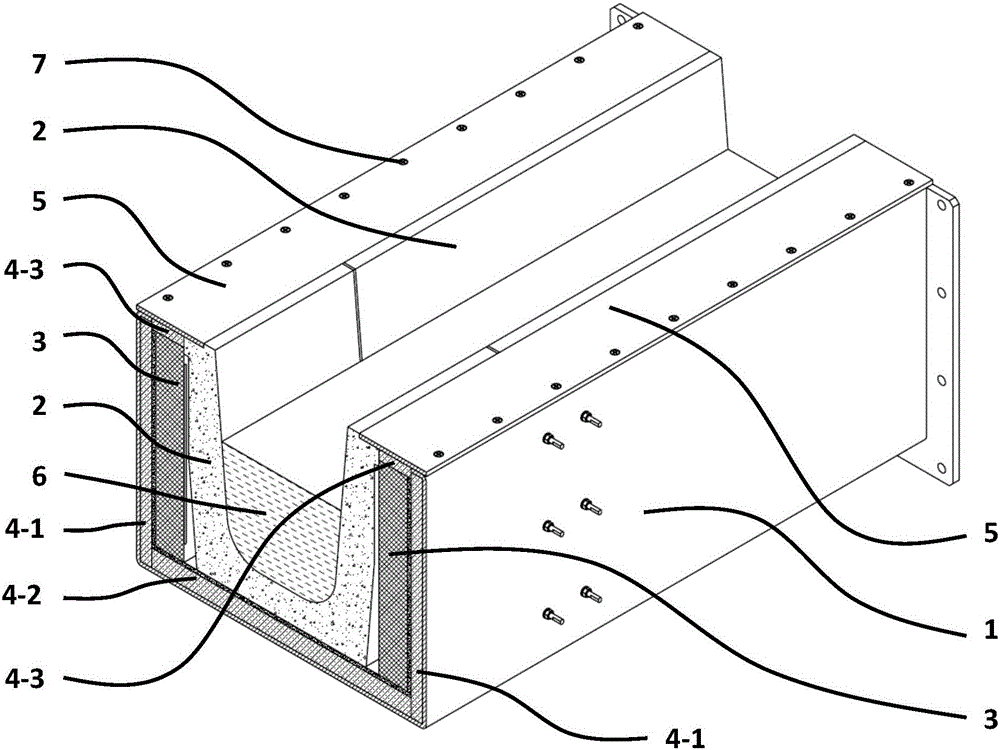

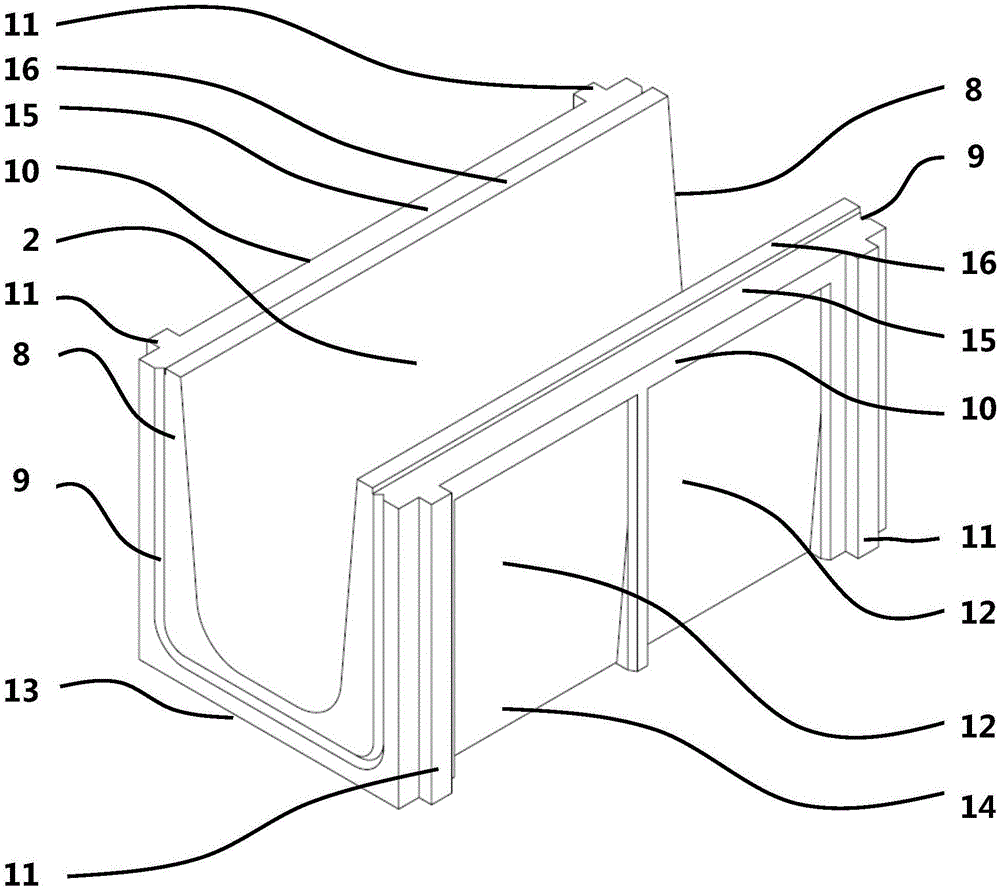

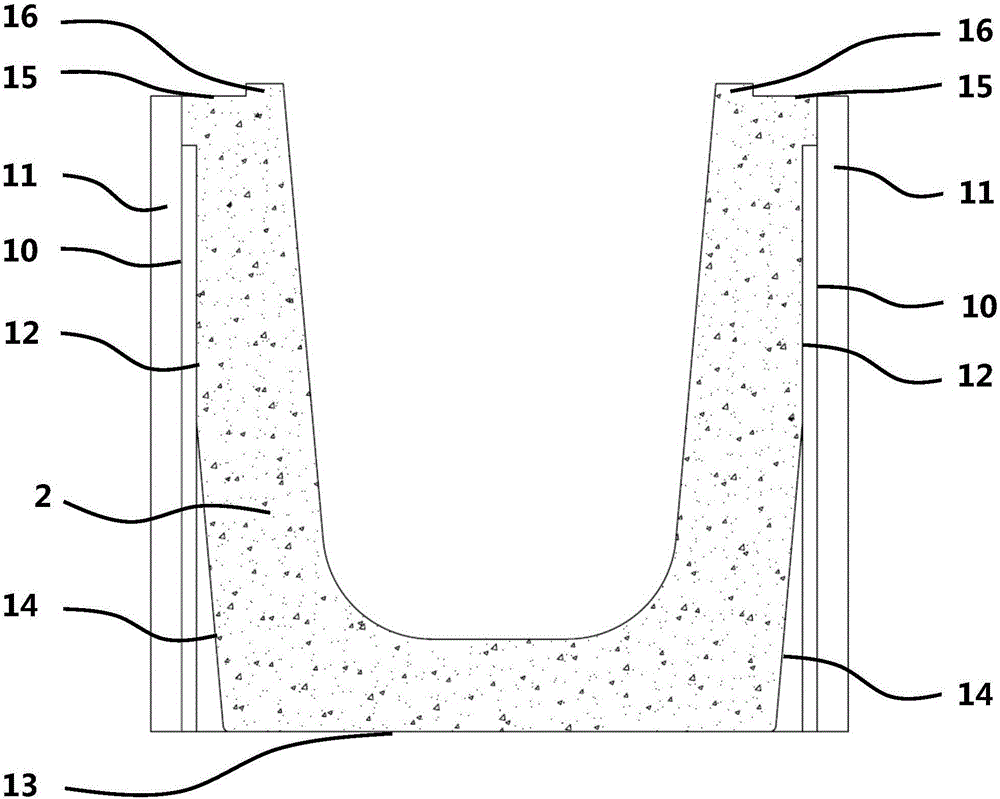

[0029] Below in conjunction with accompanying drawing, technical scheme of the present invention is described as follows:

[0030] As shown in the accompanying drawings, the pre-embedded electric heating launder of the present invention adopts a pre-embedded launder body, and the launder body is mainly composed of an iron shell 1, several connected inner linings 2, an electric heating module 3, an insulation layer and a cover The electric heating module 3 is installed on both outer sides of the inner lining 2, and the outer side of the electric heating module 3 is provided with an iron shell 1 wrapping the electric heating module 3 and the inner substrate surface, and the top surface of the inner lining 2 is provided with a The cover plate 5 fixedly connected to the iron shell 1, the cover plate 5 is fixed on the top of the iron shell 1 by screws 7, and is close to the top surface 15 of the inner lining 2 and the top of the upper insulation layer 4-3; the electric heating modul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com