Digital controlled swinging mechanism for polishing aspheric optical element

An optical element and aspheric technology, which is used in optical surface grinders, grinding/polishing equipment, grinding machine parts, etc. Processing efficiency and processing accuracy, reduction of intermediate frequency error, and the effect of light driving part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with embodiment now.

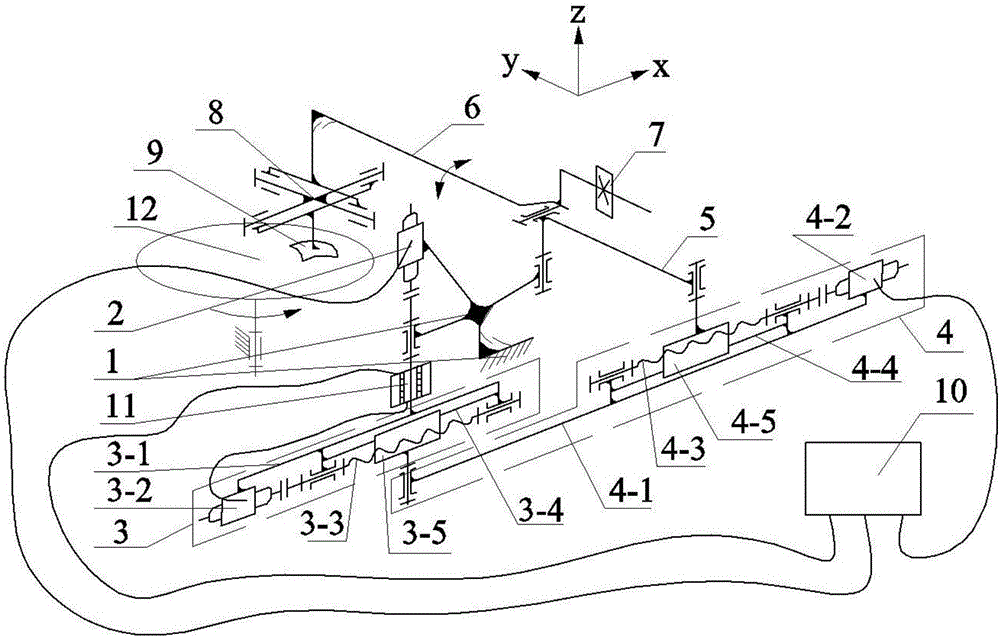

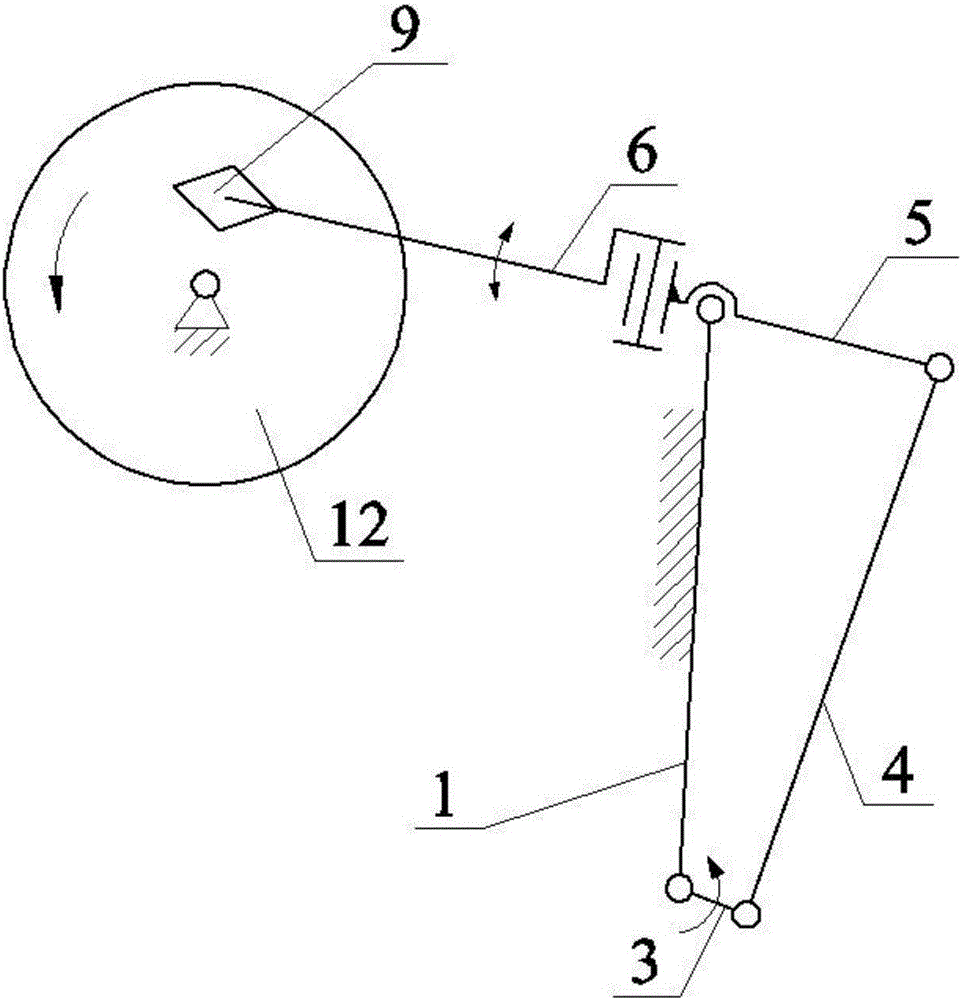

[0029] see figure 1 , figure 1 It is a schematic diagram of the structure of the CNC pendulum used for polishing aspheric optical elements in the present invention, including a frame 1, a spindle motor 2, an electronically controlled crank 3, an electronically controlled connecting rod 4, a rocker 5, a swing arm 6, a counterweight 7, and a cross Universal joint 8, polishing disc 9, controller 10 and electric slip ring 11, described electric control crank 3 comprises crank frame 3-1, crank motor 3-2, crank screw rod 3-3, crank guide rail 3-4 And crank slide table 3-5, described electric control connecting rod 4 comprises connecting rod frame 4-1, connecting rod motor 4-2, connecting rod screw rod 4-3, connecting rod guide rail 4-4 and connecting rod slide table 4-5;

[0030] The crank frame 3-1, crank motor 3-2, crank screw 3-3, crank guide rail 3-4 and crank slide table 3-5 of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com