Dense paste premixing method for improving properties of building garbage recycled aggregate concrete

A technology for recycling aggregates and construction waste, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc. Recycled concrete from waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through specific embodiments :

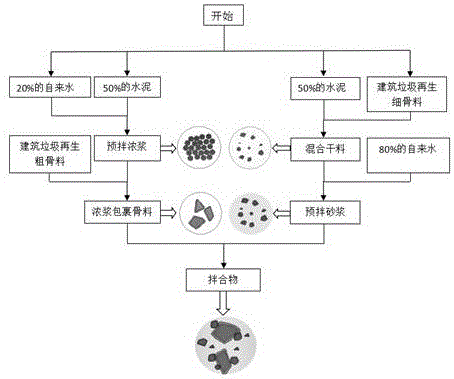

[0020] Such as figure 1 The shown a kind of ready-mixed thick slurry method to improve the performance of construction waste recycled aggregate concrete, according to the set mix ratio, firstly take a part of water (a) and a part of cement (b) to form a ready-mixed thick slurry; secondly, Mix the ready-mixed thick slurry with the construction waste recycled coarse aggregate (c) to prepare the thick slurry wrapped aggregate; again, mix the remaining cement (1-b) and the construction waste recycled fine aggregate (d) to form a mixed dry Mix the mixed dry material and the remaining water (1-a) to form a ready-mixed mortar; finally, mix the thick slurry coating and ready-mixed mortar evenly to obtain construction waste recycled aggregate concrete;

[0021] c: When d =0.44~1, a=19%~21%, b=48%~52%, 1-a=79%~81%, 1-b=48%~52%;

[0022] c: When d is large, a and b take large values, otherw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com