Printing device of printing face fabric

A printing and fabric technology, applied in the field of printing devices and printing devices for printing fabrics, can solve problems such as hindering the adhesion of printing patterns, affecting printing quality, and increasing the area of fabric pollution, so as to improve work stability, speed up transportation, and ensure The effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

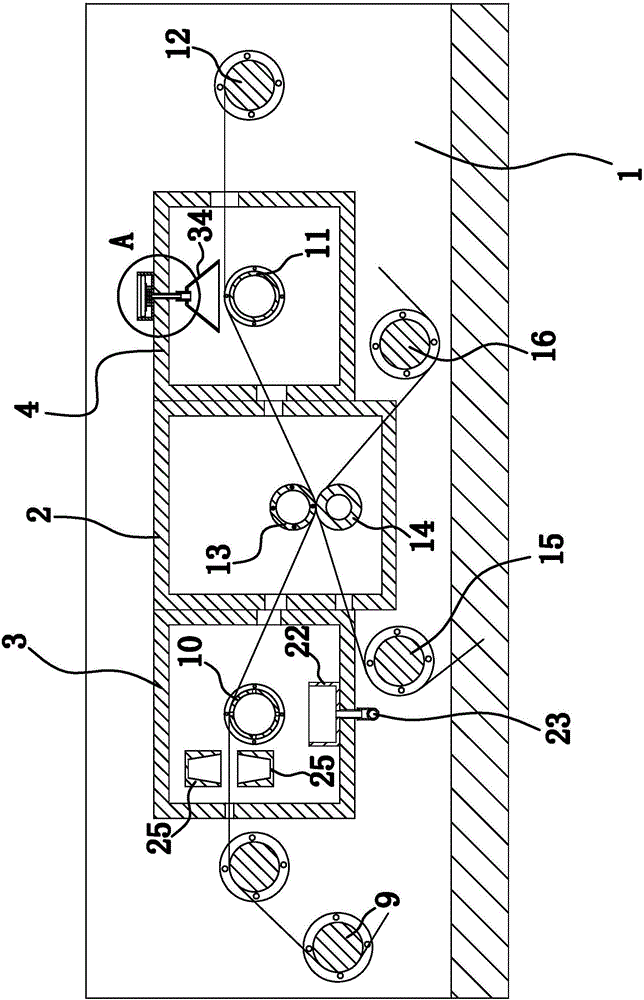

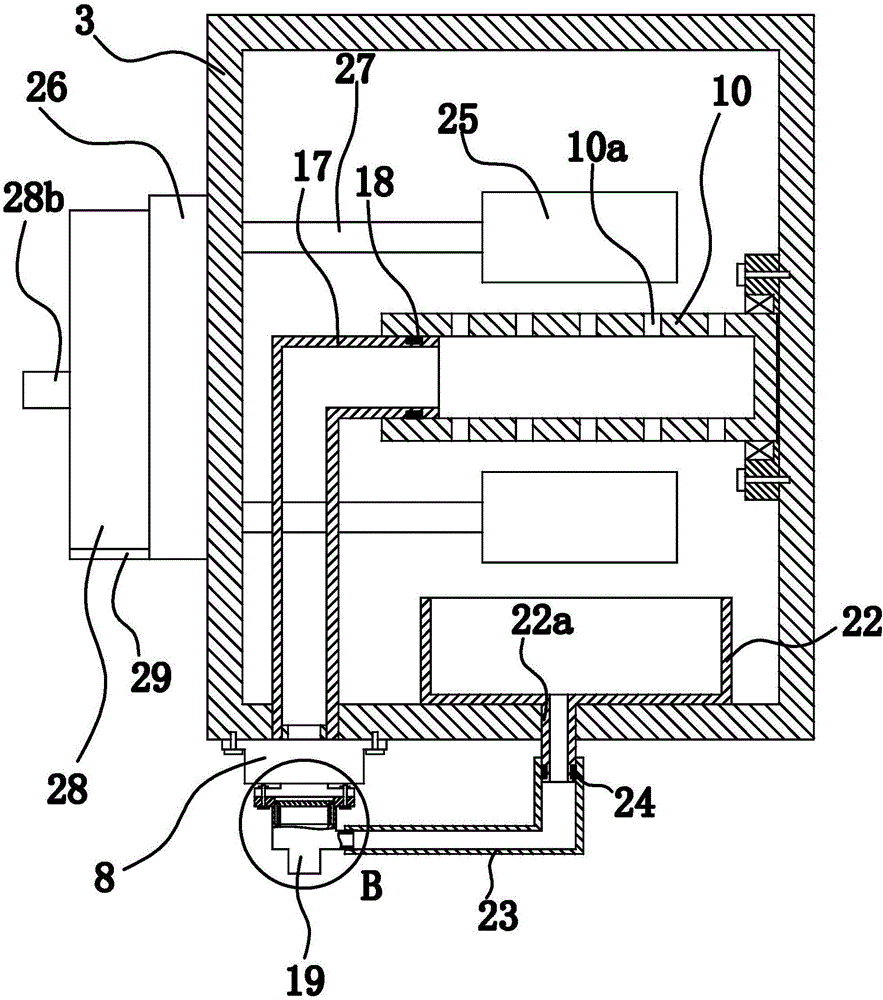

[0059] Such as figure 1 As shown, the printing device of this printed fabric is composed of frame 11, printing chamber 2, humidification and dust removal chamber 3, drying chamber 4, cloth feeding mechanism, paper feeding mechanism, exhaust fan 5, heater 6, vacuum cleaner 7, etc., water pump 8 and so on. Among them, the heater 6 and the vacuum cleaner 7 are existing products, such as a heater [application number: 201220183279.8] and a vacuum cleaner [application number: 201280008849.2] disclosed in the Chinese patent database.

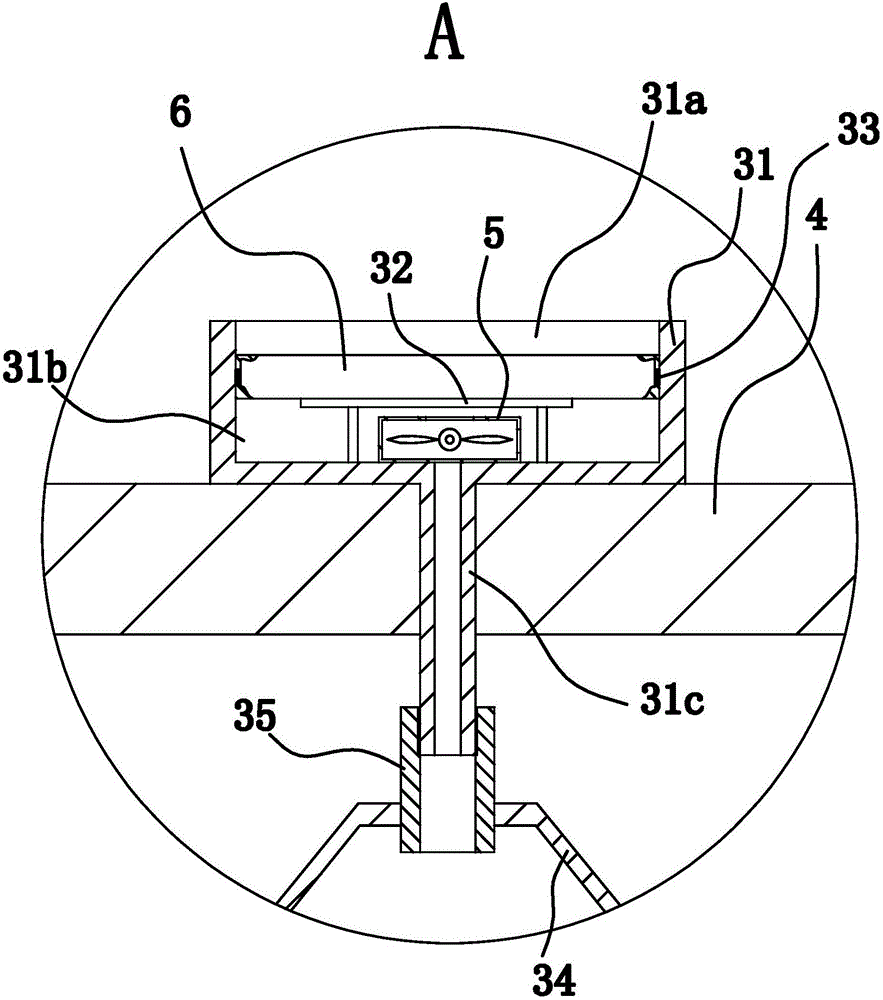

[0060] Specifically, the longitudinal section of the bracket 32 is L-shaped, and the bracket 32 includes a vertically arranged installation part 1 and a horizontally arranged installation part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com