Automatic packaging system for carbon tetrachloride standard sample and work method of automatic packaging system

A packaging system, carbon tetrachloride technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of increasing labor procedures and labor intensity of operators, low degree of automation, and affecting standard sample determination, etc., to reduce Effect of labor process and labor intensity, reduction of labor intensity, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

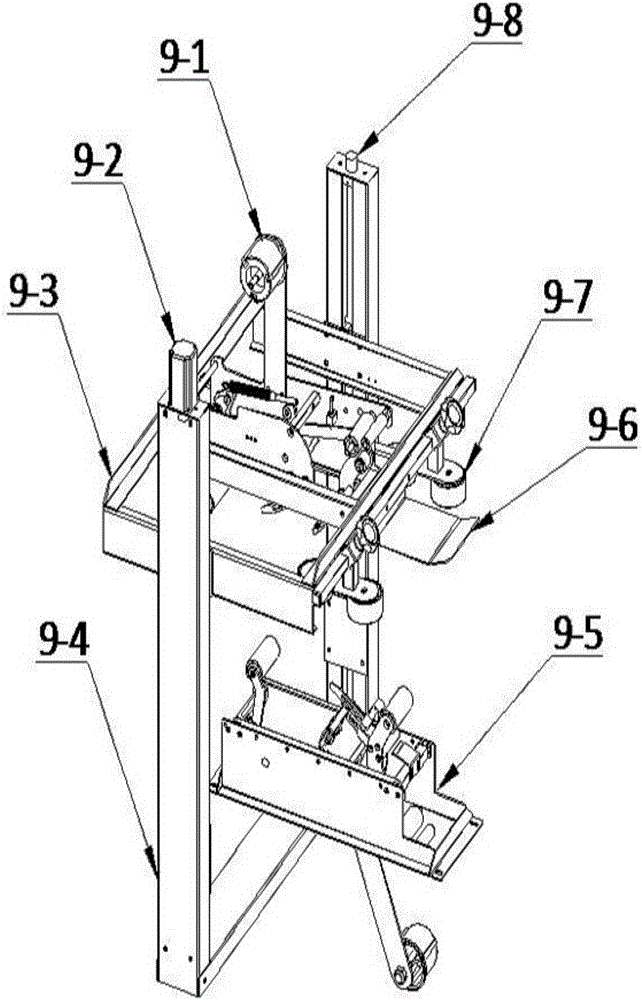

[0048] Manufacture adhesive tape fixed wheel 9-5-2 of the present invention according to the following steps, and in parts by weight:

[0049]Step 1: Add 1350 parts of ultrapure water with a conductivity of 6.56μS / cm into the reactor, start the agitator in the reactor at a speed of 98rpm, start the heating pump, and raise the temperature in the reactor to 89°C; add in sequence 4-[(5-cyano-1,6-dihydro-2-hydroxy-1,4-dimethyl-6-oxo-3-pyridyl)azo]benzoic acid-2-phenoxyethyl 72 parts of base ester, 128 parts of 4-(1,1-dimethylethyl)cyclohexanediol peroxodicarboxylate, 86 parts of 3-(2-methoxyphenoxy)-1,2-propanediol 1-carbamate part, stir until completely dissolved, adjust the pH value to 8.8, adjust the speed of the agitator to 152rpm, the temperature is 124°C, and the esterification reaction takes 8 hours;

[0050] Step 2: Take 2,2'-(3,3'-dichloro-1,1'-biphenyl-4,4'-bisazo)bis[N-(2-methoxyphenyl)- 3-oxo-butyramide] 213 parts, 6,6'(2,2'-dimethoxy-4,4'-biphenylene disazo) bis-(5-...

Embodiment 2

[0055] Manufacture adhesive tape fixed wheel 9-5-2 of the present invention according to the following steps, and in parts by weight:

[0056] Step 1: Add 2460 parts of ultrapure water with a conductivity of 8.46μS / cm into the reactor, start the stirrer in the reactor at a speed of 126rpm, start the heating pump, and raise the temperature in the reactor to 142°C; add in sequence 4-[(5-cyano-1,6-dihydro-2-hydroxy-1,4-dimethyl-6-oxo-3-pyridyl)azo]benzoic acid-2-phenoxyethyl 155 parts of base ester, 215 parts of peroxodicarboxylic acid-4-(1,1-dimethylethyl)cyclohexanediester, 165 parts of 1-carbamate 3-(2-methoxyphenoxy)-1,2-propanediol part, stir until completely dissolved, adjust the pH value to 10.6, adjust the speed of the agitator to 213rpm, the temperature is 176°C, and the esterification reaction takes 18 hours;

[0057] Step 2: Take 2,2'-(3,3'-dichloro-1,1'-biphenyl-4,4'-bisazo)bis[N-(2-methoxyphenyl)- 3-oxo-butanamide] 288 parts, 6,6'(2,2'-dimethoxy-4,4'-biphenylene di...

Embodiment 3

[0062] Manufacture adhesive tape fixed wheel 9-5-2 of the present invention according to the following steps, and in parts by weight:

[0063] Step 1: Add 1900 parts of ultrapure water with a conductivity of 7.51μS / cm into the reactor, start the stirrer in the reactor at a speed of 112rpm, start the heating pump, and raise the temperature in the reactor to 116°C; add in sequence 4-[(5-cyano-1,6-dihydro-2-hydroxy-1,4-dimethyl-6-oxo-3-pyridyl)azo]benzoic acid-2-phenoxyethyl 113 parts of base ester, 171 parts of peroxodicarboxylic acid-4-(1,1-dimethylethyl)cyclohexanediester, 125 parts of 1-carbamate 3-(2-methoxyphenoxy)-1,2-propanediol part, stir until completely dissolved, adjust the pH value to 9.7, adjust the speed of the agitator to 182rpm, the temperature is 150°C, and the esterification reaction takes 13 hours;

[0064] Step 2: Take 2,2'-(3,3'-dichloro-1,1'-biphenyl-4,4'-bisazo)bis[N-(2-methoxyphenyl)- 3-oxo-butanamide] 250 parts, 6,6'(2,2'-dimethoxy-4,4'-biphenylene dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com