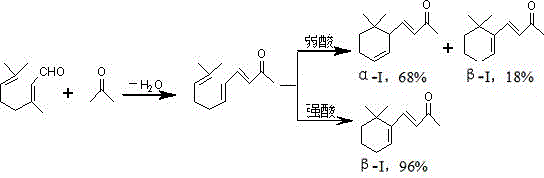

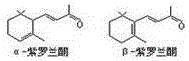

Preparation method capable of improving yield of alpha-isomer in ionone product

A technology of ionone and pseudo-ionone, which is applied in the field of preparation to increase the yield of α-isomers in ionone products, can solve the problems of the lack of optimal performance of ionone series products and poor aroma, and achieve the goal of preparing The method is simple and the effect of increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method for improving the α-isomer output in the ionone product of the present invention comprises the following steps:

[0027] (1) Prepare pseudo-ionone products and ionone post-distillate products with a β-isomer content of more than 35%, for subsequent use;

[0028] (2), carry out the acidification cyclization reaction that inhibits the formation of β-isomers with the fraction after ionone: add acid solution and organic solvent accounting for 1 / 2 of the total catalyst acid solution in the container (reactor or flask), and then Add a certain amount of ionone fraction with the above-mentioned β-isomer content above 35% into the container and stir evenly, heat up to 35-80°C, and then start to add pseudo-ionone dropwise for 1-3 hours. After the dropwise addition is completed, add the remaining 1 / 2 of the acid solution, and continue to maintain the temperature and stir for 1-4 hours;

[0029] (3) After the reaction is completed and left to stand, slowly s...

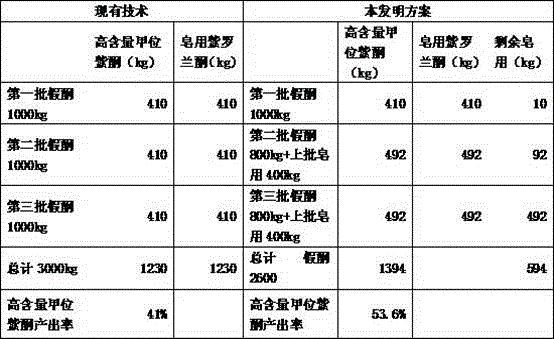

Embodiment 1

[0039] Add 400g of benzene and 50g of phosphoric acid with a mass concentration of 85% into a 2000ml three-neck flask, stir well, then raise the temperature to 35-50°C, add 160g of ionone after the fraction (α-isomer content 50%, β-isomer content 35%), then start to drop 400g of pseudo-ionone, and control the dropping time for 1.5-3 hours. After the drop of pseudo-ionone is completed, add the remaining 50g of phosphoric acid; then raise the temperature to 50~55℃ to keep the reaction for 2- After 3 hours, follow the reaction process by chromatography until the PI content is ≤2%, stop stirring, and let stand to separate layers. After standing still, slowly separate the viscous acid solution in the lower layer (the acid solution is weighed, and it can be recycled after adding a small amount of fresh to a sufficient amount in the next batch). The upper organic phase is washed with soda water and brine until it is neutral. After recovering benzene, vacuum distillation is carried ou...

Embodiment 2

[0042] Add 400g of toluene and 100g of phosphoric acid with a mass concentration of 85% into a 2000ml three-necked flask, stir evenly, then raise the temperature to 35-50°C, add 160g of the ionone for soap obtained in the above example (the content of α-isomer is 53%, the content of β- Isomer content is about 35%), then start to drop 400g of pseudo-ionone, control the dropping time for 1.5-3 hours, after the addition of pseudo-ionone is completed, add the remaining 100g of phosphoric acid; Keep the reaction at ℃ for 2-3 hours, follow the reaction process by chromatography until the PI content is ≤2%, stop stirring, and let it stand for stratification. After standing still, slowly separate the viscous acid solution in the lower layer (the acid solution is weighed, and it can be recycled after adding a small amount of fresh to a sufficient amount in the next batch). The upper organic phase was washed with soda water and brine until it was neutral. After recovering the toluene, v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com