A kind of rigid biomass composite material and preparation method thereof

A composite material and biomass technology, applied in the field of biomass material utilization, can solve problems such as low linear thermal expansion coefficient, low melting point, and large environmental damage, and achieve low linear thermal expansion coefficient, high creep recovery rate, and excellent comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

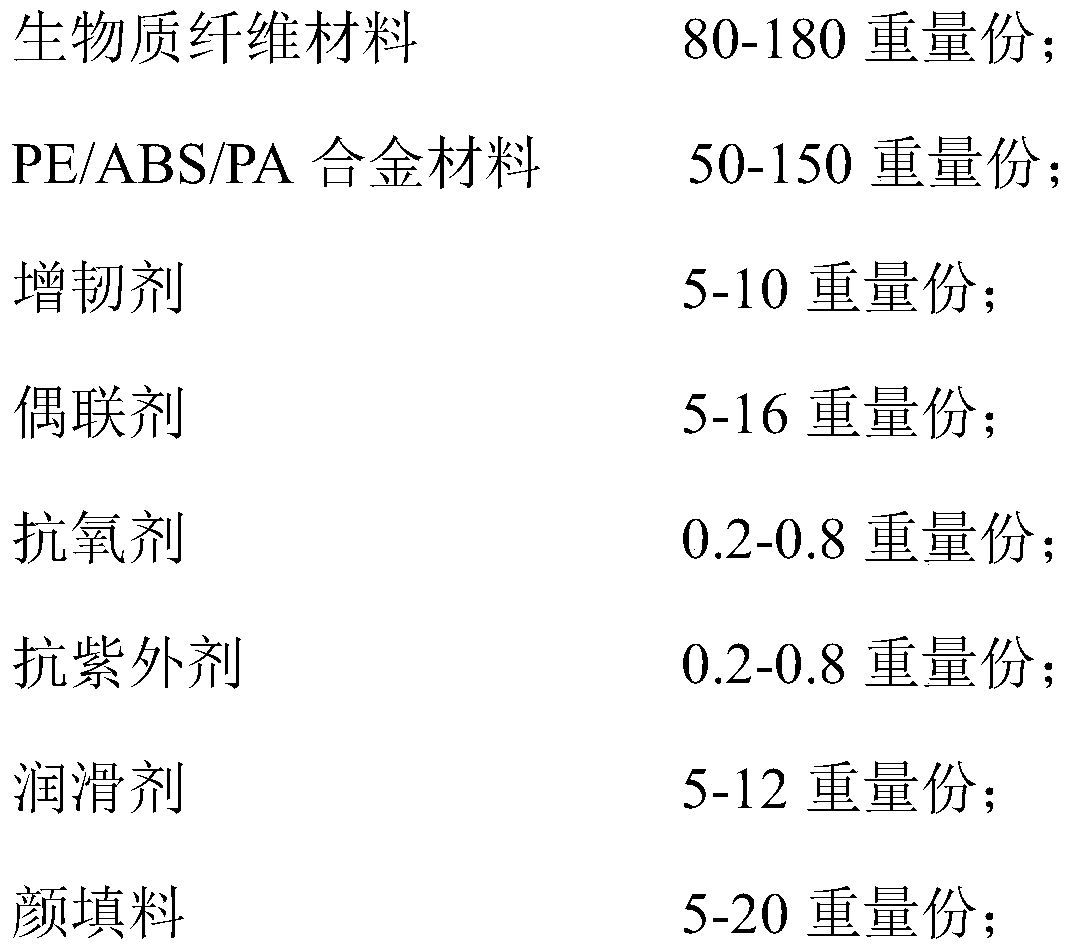

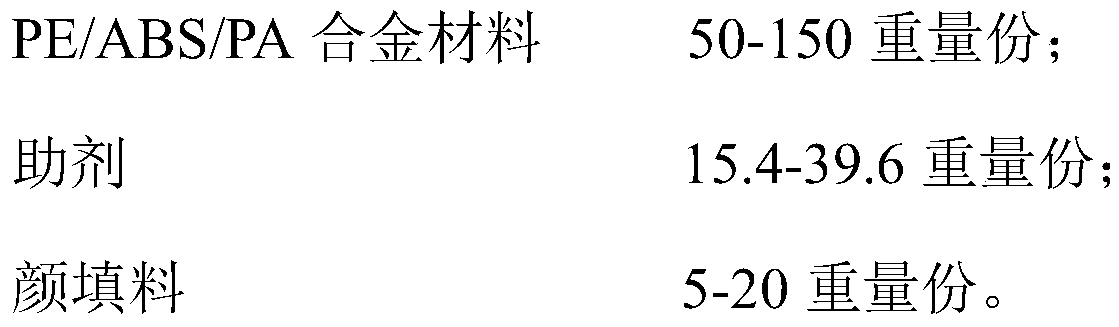

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 prepares heterogeneous composite compatibilizer

[0045] Take the graft or block copolymer of PE (maleic anhydride grafted PE), the graft or block copolymer of ABS (maleic anhydride grafted ABS) and the graft of PA with a mass ratio of 4:3:3. Branch or block copolymer (maleic anhydride grafted PA) mixes, and adds the dicumyl peroxide initiator that accounts for 0.08wt% of described heterogeneous composite compatibilizer gross weight, mixes and obtains required polyamide Compatibilizer.

Embodiment 2

[0046] Embodiment 2 prepares heterogeneous composite compatibilizer

[0047] Take the graft or block copolymer of PE (maleic anhydride grafted PE), the graft or block copolymer of ABS (maleic anhydride grafted ABS) and the PE of PA with a mass ratio of 4:3:3. The graft or block copolymer (maleic anhydride grafted PA) mixes, and adds the dicumyl peroxide initiator accounting for 0.12wt% of the heterogeneous composite compatibilizer gross weight, mixes and obtains A multiphase composite compatibilizer is required.

Embodiment 3

[0048] Embodiment 3 prepares PE / ABS / PA alloy

[0049] Get 40kg of HDPE (5000s), 20kg of ABS (ABS 0215A), 40kg of PA (nylon PA11), and 10kg of the multiphase composite compatibilizer prepared in Example 1, and mix them evenly, and dry them at 80°C for 4h; then add them to Blend in a blender at a speed of 200r / min for 10min; after blending, extrude and modify through a parallel twin-screw granulator to obtain a PE / ABS / PA alloy.

[0050] The parallel twin-screw granulator is divided into nine temperature zones from the inlet to the outlet, and its process parameters are shown in Table 1 below.

[0051] The processing parameter of parallel twin-screw granulator in the embodiment 1 of table 1

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com