A kind of multipurpose neutral release agent and preparation method thereof

A multi-purpose, release agent technology, used in manufacturing tools, casting and molding equipment, metal processing equipment, etc., can solve problems such as environmental pollution and release effect, achieve reduced environmental pollution, excellent release effect, and uniform film formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

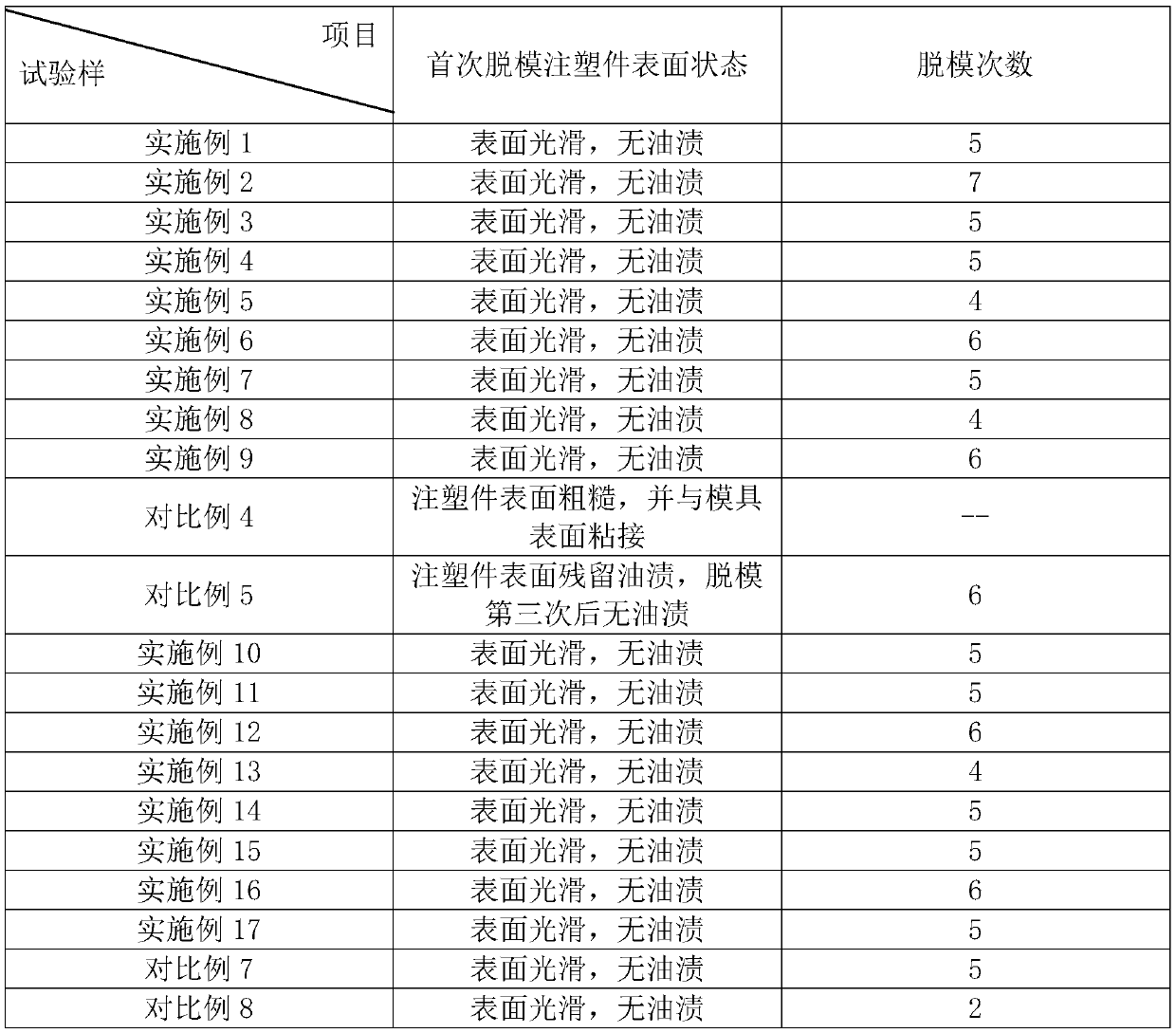

Examples

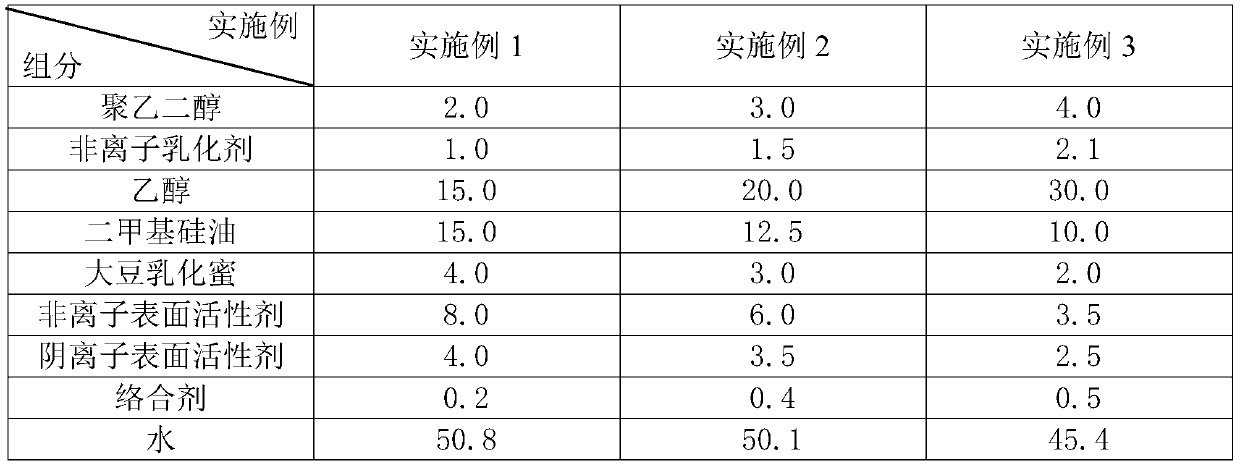

Embodiment 1-3

[0040]Embodiment 1-3: A multi-purpose neutral release agent, the ingredients and formula are shown in Table 1, prepared by the following process:

[0041] S1: Weigh the polyethylene glycol of the recipe amount, add the ethanol of the recipe amount, stir evenly, then add the nonionic emulsifier of the recipe amount and stir until dissolved as component A;

[0042] S2: Weigh the formulated amount of simethicone oil, add the formulated amount of soybean emulsified honey and stir, then add the formulated amount of nonionic surfactant and stir evenly as component B;

[0043] S3: Weigh the water of the formula amount, add the anionic surfactant and the complexing agent of the formula amount, stir and dissolve evenly as component C;

[0044] S4: Slowly add component A and component B to component C under high-speed stirring at 2800rpm, and stir at 78-84°C for 60 minutes to obtain a milky white substance, which is a multi-purpose neutral release agent;

[0045] Among them, the molecu...

Embodiment 4

[0048] Embodiment 4: The difference with embodiment 2 is that the molecular weight of polyethylene glycol is 800.

Embodiment 5

[0052] Embodiment 5: The difference from Embodiment 2 is that the nonionic emulsifier is polyoxyethylene sorbitan monolaurate (Tween-20).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com