Ship metal component coated with rare earth ceramic electric insulation coating and preparation method of ship metal component

A technology of ceramic coating and metal parts, which is applied to the metal parts coated with rare earth ceramic electrical insulating coating for ships and the field of preparation thereof, and can solve the problems of short service life of ships and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

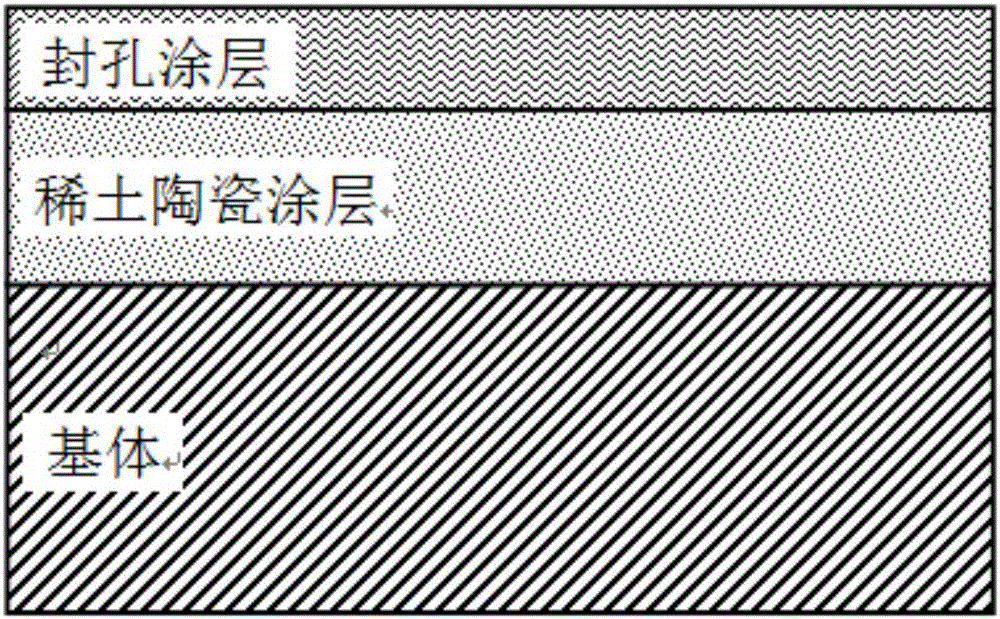

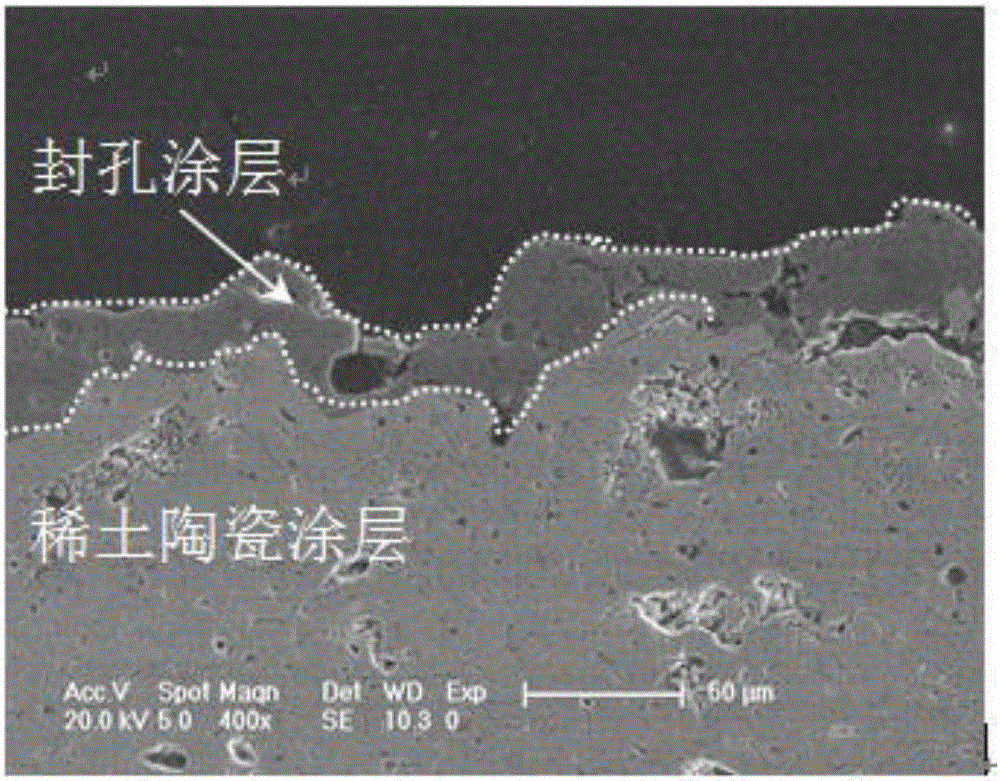

[0050] Embodiment 1: the end face of the metal base is roughened by sand blasting with a particle size of 0.42 to 0.85mm, and then a 0.03mm thick YSZ layer (Y 2 o 3 The mass percentage is 3%, and the rest is ZrO 2 ); the surface of the YSZ layer is coated with 0.03mm thick polyurea as the sealing layer, and the appearance of the prepared rare earth ceramic electrical insulating coating is shown in figure 2 , its resistance ≥ 700MΩ. Wherein the bonding strength between the YSZ layer and the metal substrate is ≥ 20MPa, and the bonding strength between the YSZ layer and the polyurea layer is ≥ 10MPa. After 11MPa and 48 hours of water pressure, the rare earth ceramic electrical insulation coating did not experience any water seepage.

Embodiment 2

[0051] Embodiment 2: The end face of the metal substrate is roughened by sand blasting with a particle size of 0.42mm to 0.85mm, and then a 0.5mm thick YSZ layer (Y 2 o 3 The mass percentage is 12%, and the rest is ZrO 2 ); the surface of the YSZ layer is coated with a 0.1mm thick fluorocarbon coating as a sealing layer, and the resistance of the prepared rare earth ceramic electrical insulation coating is ≥700MΩ. Among them, the bonding strength between the YSZ layer and the metal substrate is ≥ 20MPa, and the bonding strength between the YSZ layer and the fluorocarbon coating layer is ≥ 10MPa.

Embodiment 3

[0052] Embodiment 3: the metal substrate end face is roughened by sand blasting with a particle size of 0.42mm to 0.85mm, and then sprayed with a 0.3mm thick YSZ layer (Y 2 o 3 The mass percentage is 6%, and the rest is ZrO 2 ); the surface of the YSZ layer is coated with a 0.05mm thick fluorocarbon coating as a sealing layer, and the resistance of the prepared rare earth ceramic electrical insulation coating is ≥700MΩ. Among them, the bonding strength between the YSZ layer and the metal substrate is ≥ 20MPa, and the bonding strength between the YSZ layer and the fluorocarbon coating layer is ≥ 10MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com