A rare earth ion ln3+ doped gadolinium strontium aluminate laser crystal

A rare earth ion, laser crystal technology, applied in lasers, crystal growth, phonon exciters, etc., can solve the problems of narrow absorption spectrum, unsuitable for laser diode pumping, etc. The effect of good thermal and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

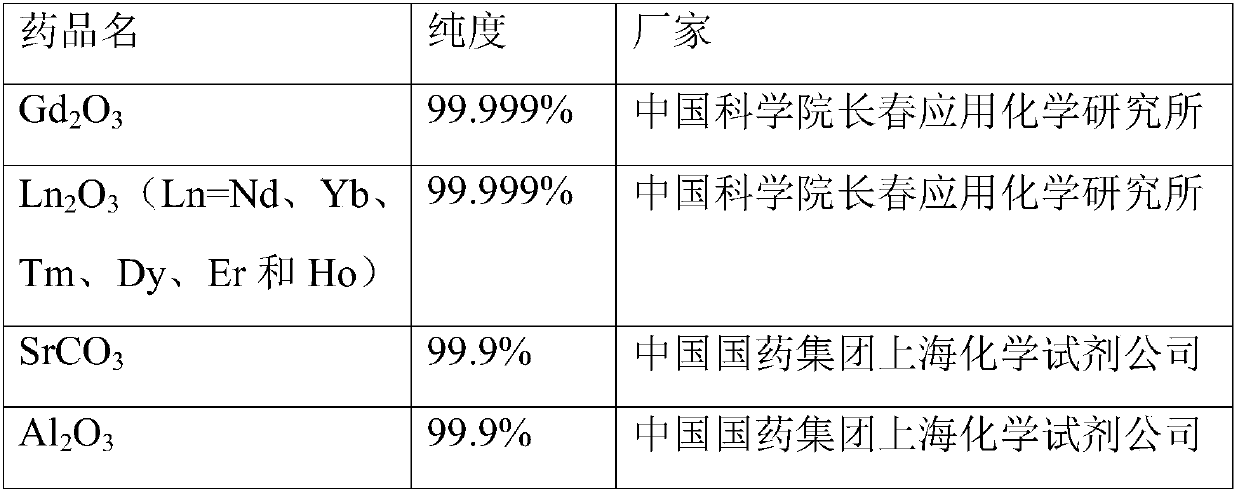

[0019] Example 1: Growth of Tm by pulling method 3+ :Gd 2 SrAl 2 o 7 single crystal.

[0020] Will be according to molecular formula Tm 2x Gd 2-2x SrAl 2 o 7 (x=0.001, 0.004, 0.2, 0.3, 0.5) in the molar ratio of each substance accurately weighed Tm 2 o 3 、Gd 2 o 3 , SrCO 3 and Al 2 o 3 Mix and grind evenly. After tableting, react in solid phase at 1200°C for 24 hours in a muffle furnace. After taking it out, grind and tablet again, and heat up to 1500°C for 24 hours. Load the above synthesized samples into In the iridium gold crucible, put it into the pulling furnace, adopt the pulling method, in N 2 In the atmosphere, when the growth temperature is 1780°C, the crystal rotation speed is 10 rpm, and the pulling speed is 1 mm / h, large-sized, high-quality Tm 3+ :Gd 2 SrAl 2 o 7 single crystal.

Embodiment 2

[0021] Example 2: Growth of Nd by pulling method 3+ :Gd 2 SrAl 2 o 7 single crystal.

[0022] will be according to the molecular formula Nd 2x Gd 2-2x SrAl 2 o 7 (x=0.001, 0.005, 0.1, 0.3, 0.5) in the molar ratio of each substance accurately weighed Nd 2 o 3 、Gd 2 o 3 , SrCO 3 and Al 2 o 3 Mix and grind evenly. After tableting, react in solid phase at 1200°C for 24 hours in a muffle furnace. After taking it out, grind and tablet again, and heat up to 1500°C for 24 hours. Load the above synthesized samples into In the iridium gold crucible, put it into the pulling furnace, adopt the pulling method, in N 2 In the atmosphere, when the growth temperature is 1780 °C, the crystal rotation speed is 15 rpm, and the pulling speed is 0.5 mm / h, large-size, high-quality Nd 3+ :Gd 2 SrAl 2 o 7 single crystal.

Embodiment 3

[0023] Example 3: Growth of Yb by pulling method 3+ :Gd 2 SrAl 2 o 7 single crystal.

[0024] will be according to the molecular formula Yb 2x Gd 2-2x SrAl 2 o 7 (x=0.001, 0.008, 0.15, 0.25, 0.5) in the molar ratio of each substance accurately weighed Yb 2 o 3 、Gd 2 o 3 , SrCO 3 and Al 2 o 3 Mix and grind evenly. After tableting, react in solid state at 1200°C for 24 hours in a muffle furnace. After taking it out, grind and tablet again, and heat up to 1500°C for 24 hours. Load the above synthesized samples into In the iridium gold crucible, put it into the pulling furnace, adopt the pulling method, in N 2 In the atmosphere, when the growth temperature is 1780 °C, the crystal rotation speed is 20 rpm, and the pulling speed is 0.8 mm / h, large-sized and high-quality Yb 3 + : Gd 2 SrAl 2 o 7 single crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com