Soil nailing wall supporting structure and construction method

A technology for supporting structures and soil nailing walls, which can be used in foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of difficult strength and large influence of welding points, and achieve weak shear resistance, long life and corrosion resistance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

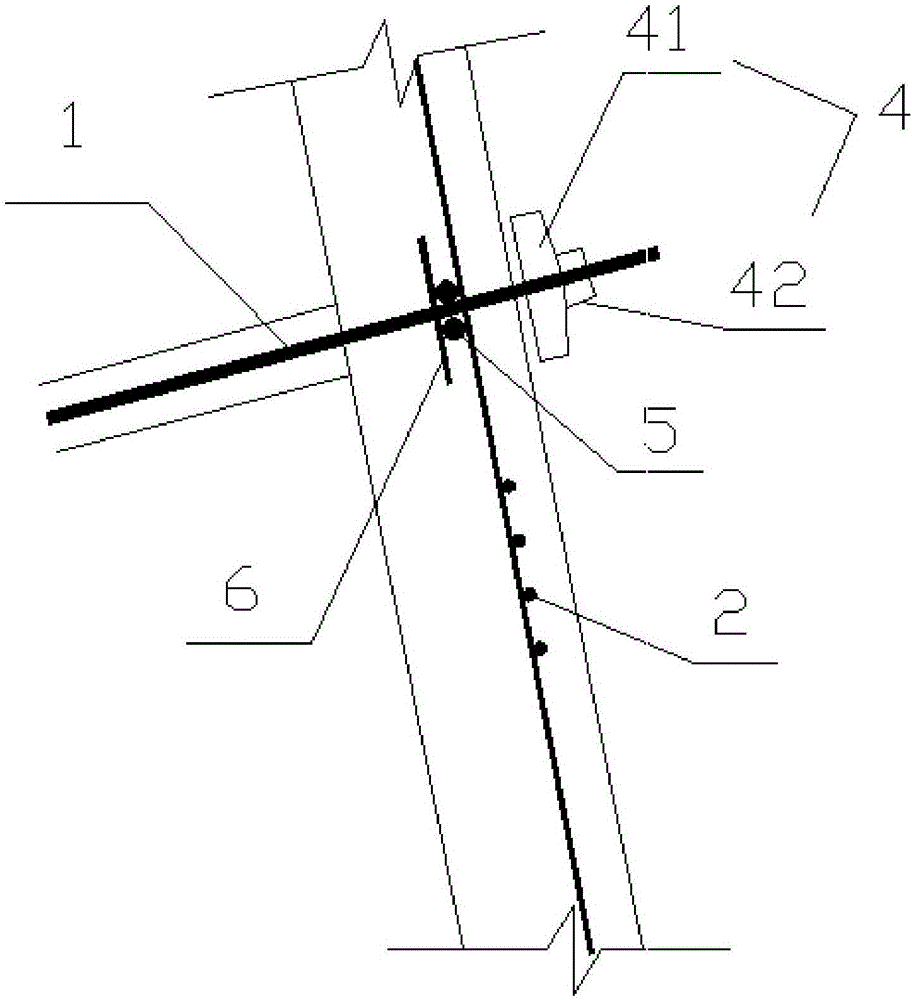

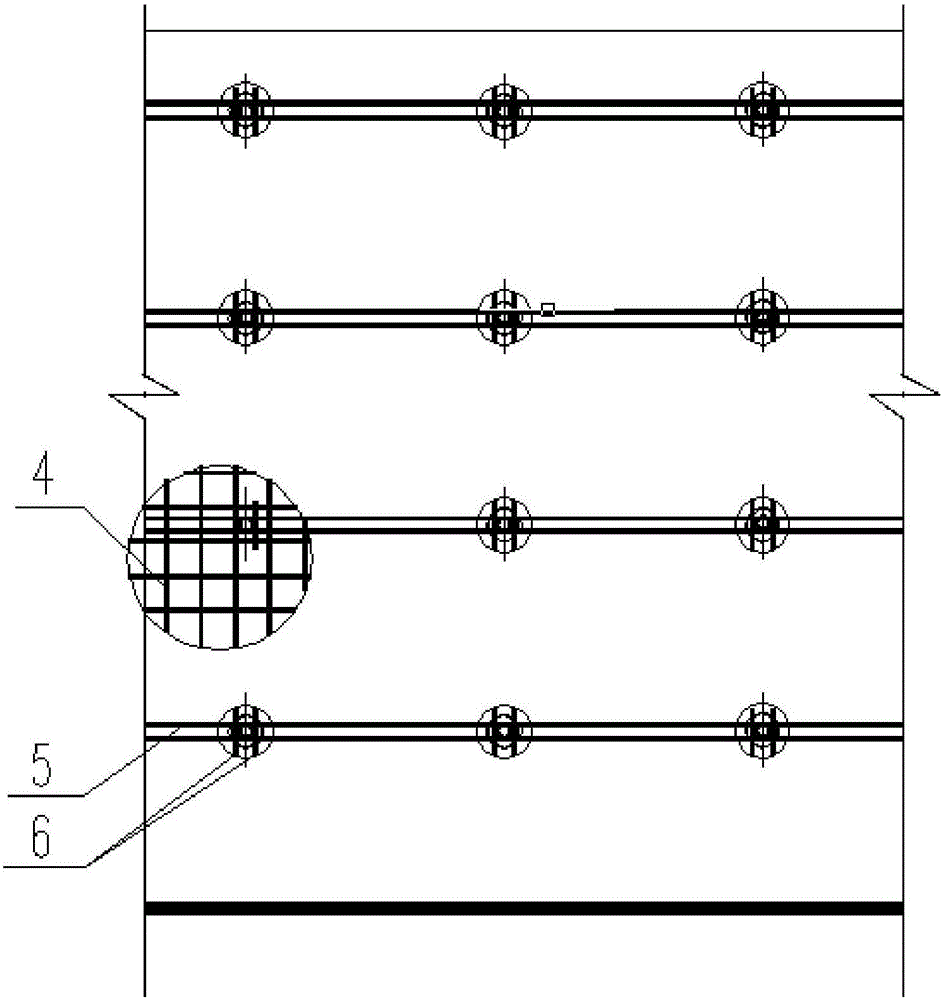

[0023] according to figure 1 , figure 2 As shown, a soil nail wall support structure includes a number of deep holes opened on the required support surface, and generally a number of deep holes are arranged in an array. Pierce the GFRP bar 1 in the deep hole and grout to form a soil nail body. Hang the reinforcement mesh 2 on the support surface; the reinforcement mesh 2 is fixed with the rod body of each GFRP bar 1 exposed to the support surface, and the reinforcement mesh 2 is sprayed to form the concrete surface layer 3 of the support surface; the outer end of the GFRP bar 1 is exposed The concrete surface layer 3 forms an anchoring end, and the soil nail body and the concrete surface layer 3 form a whole through the cooperation of the anchoring part 4 and the anchoring end of the GFRP bar 1 .

[0024] In order for several independent GFRP bars 1 to form a whole, the GFRP bars 1 in the same row are clamped up and down by two transverse bars 5 to form a whole, and short b...

Embodiment 2

[0028] The construction method of soil nail wall support structure comprises the following steps:

[0029] Drill the hole first, and then clean the hole after drilling to the set depth, then insert the GFRP bar 1 into the deep hole and grout to form the soil nail body. The cross bar 5 is clamped to form a whole, and then the grid is connected to the grid and sprayed concrete, and finally the concrete surface layer is formed. After the concrete surface layer 3 is cured to the set strength, the GFRP tendon 1 is extended out of the concrete surface layer 3 through the anchor plate. segment anchoring, so that the soil nail body and the concrete surface layer 3 form a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com