Method for forming trapezoidal drainage ditches by means of pouring on basis of adjustable groove forming molds

A technology of forming molds and forming methods, which is applied to drainage structures, buildings, waterway systems, etc., can solve the problems of long construction period, difficulty in guaranteeing the construction quality of drainage ditches, and non-reusable devices such as molds, so as to control costs and improve The effect of repeated use rate and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

[0048] When the trapezoidal drainage ditch is poured and formed, the present invention adopts an adjustable groove forming mold to form the ditch body in sections, so as to satisfy the vertical formwork construction of different slope ratio sections of the drainage ditch.

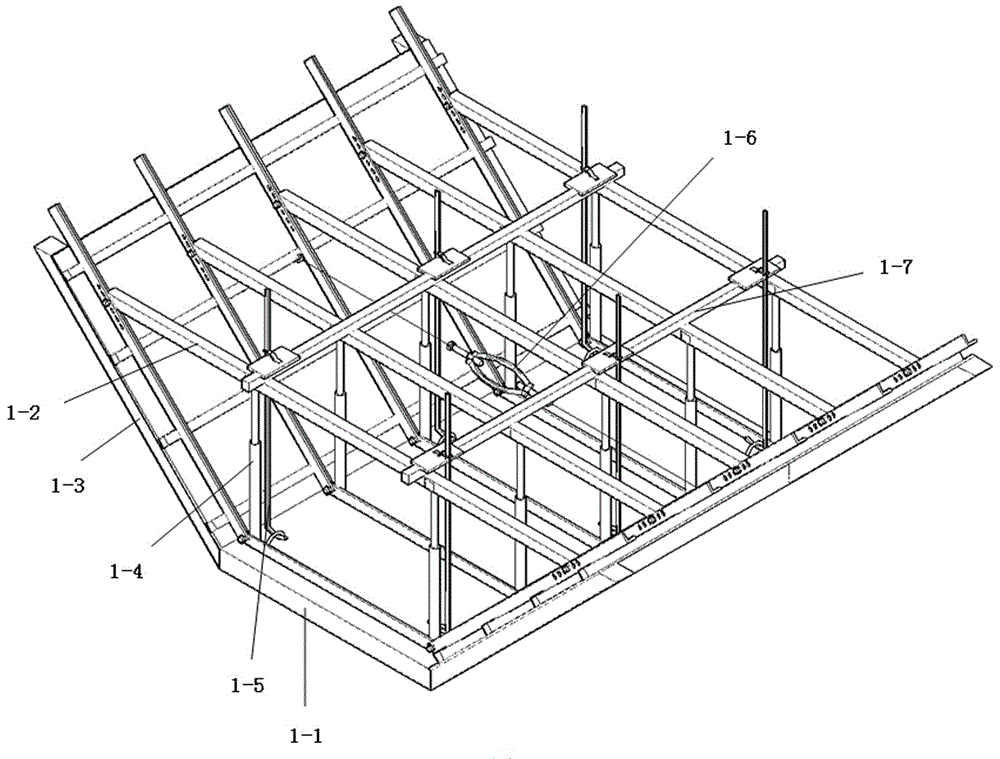

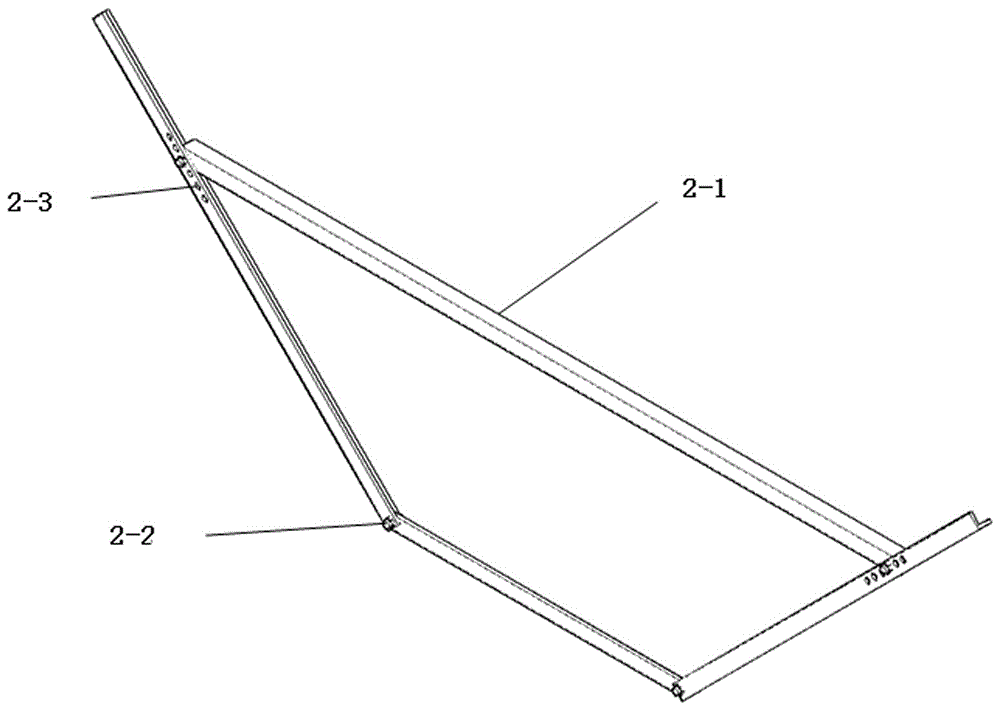

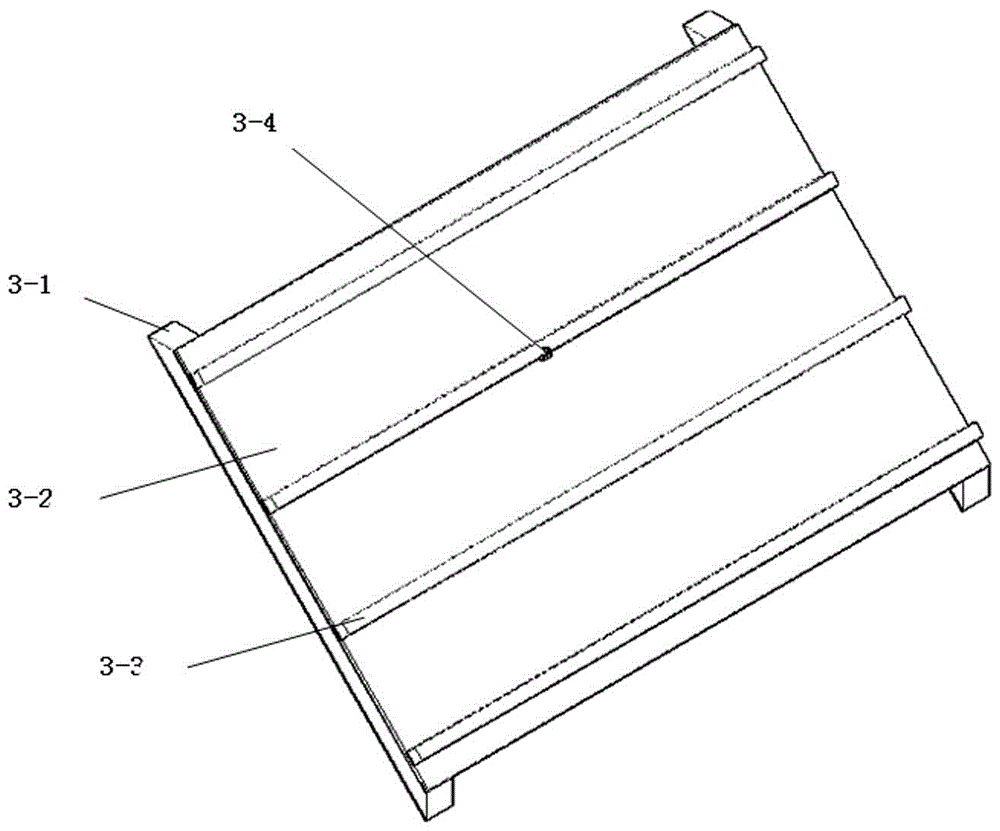

[0049] like figure 1 The adjustable groove forming mold as shown includes a vertical mold support 1-2, a wooden formwork 1-3 and a rectangular section hollow steel pipe 1-7, and two wooden formworks 1-3 are arranged close to the inner wall of the drainage ditch groove, The vertical form support 1-2 is an assembled inverted isosceles trapezoidal frame structure with the same slope ratio as the drainage ditch section, several vertical form support 1-2 are arranged in parallel, and the two waists of each vertical form support 1-2 are close to the wooden formwork 1 -3 forms a support for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com