Construction method of pre-buried filling block in cast-in-place concrete hollow floor

A hollow floor slab and construction method technology, applied in the direction of floor slabs, building components, buildings, etc., can solve the problems of unscientific fixing of filling blocks, and achieve the effect of ensuring overall mechanical properties and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

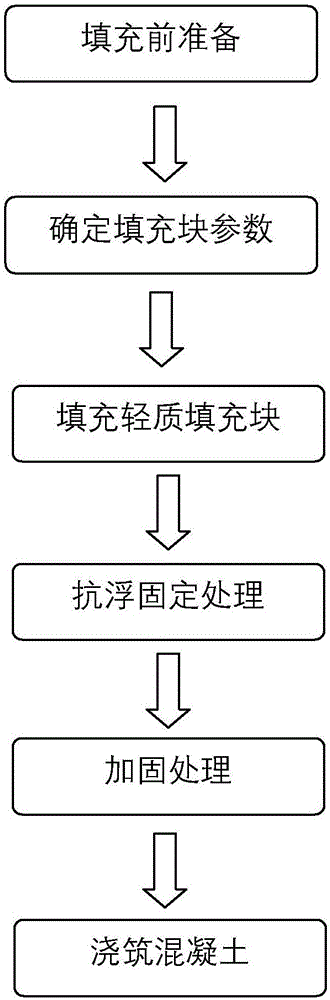

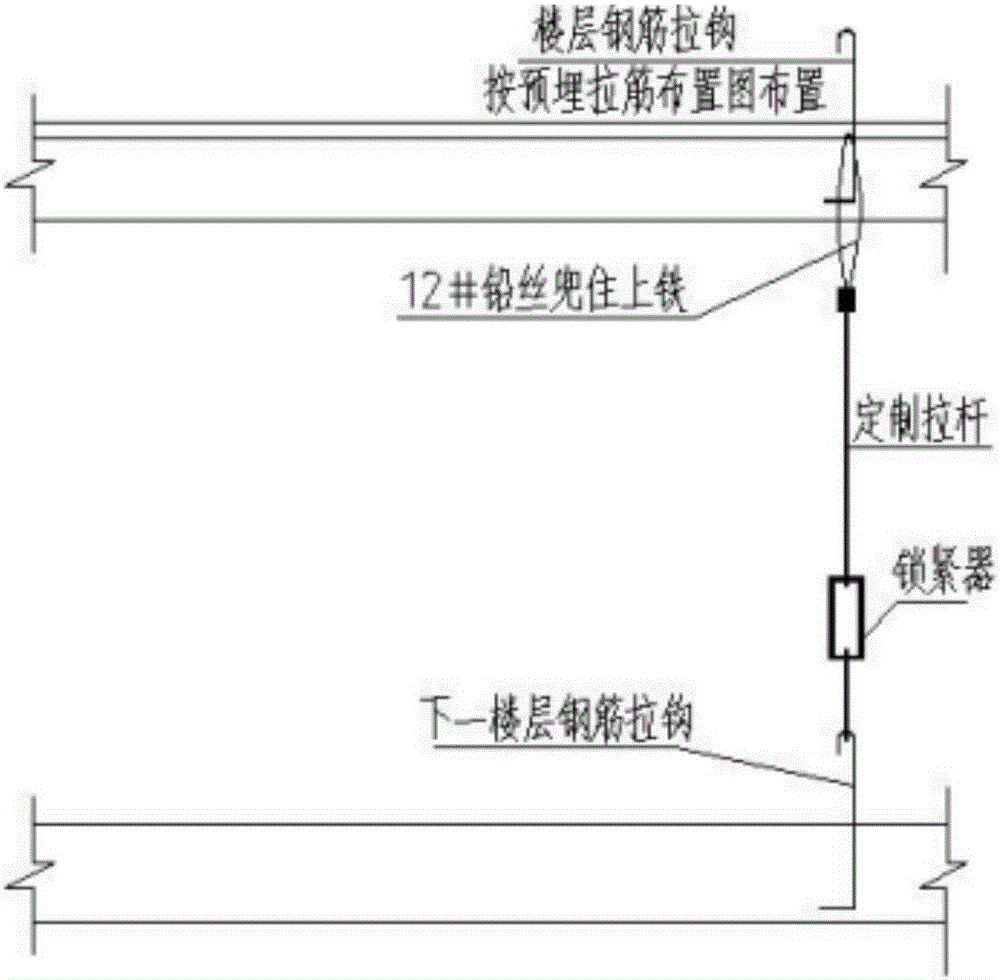

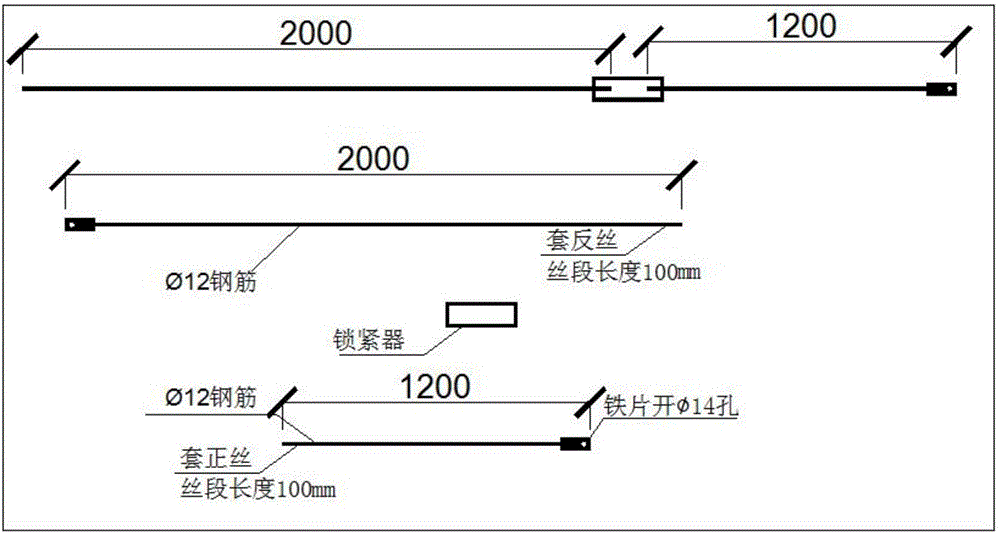

[0044] Embodiment 1, in conjunction with attached figure 1 , 2 , 3 description.

[0045] In order to solve the above technical problems, the present invention provides a construction method for pre-embedded filling blocks in cast-in-situ concrete hollow slabs, including:

[0046] Step 1, preparation before filling: set up the formwork according to the construction design requirements, draw the position line of the light filling block, the layout position of the horse stool, the layout of the anti-floating locking point, the binding of the steel bar at the bottom of the slab and the padding of the steel bar protective layer pad put;

[0047] Step 2. Determine the parameters of the lightweight filling block: the formwork of the cast-in-place concrete hollow floor determines the thickness of the floor according to the engineering structure and use; and determines the volume and position of the lightweight filling block according to the thickness of the floor and the specific ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com