Knob-type pressure regulating valve with pressure gauge and compressor provided with pressure regulating valve

A knob-type, pressure-capable technology, applied in the direction of measuring fluid pressure, liquid variable capacity machinery, measuring devices, etc., can solve the problems of increased space, falling off, and complicated appearance of the compressor device, so as to achieve the goal of not being prone to collisions and scratches , compact space, better appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

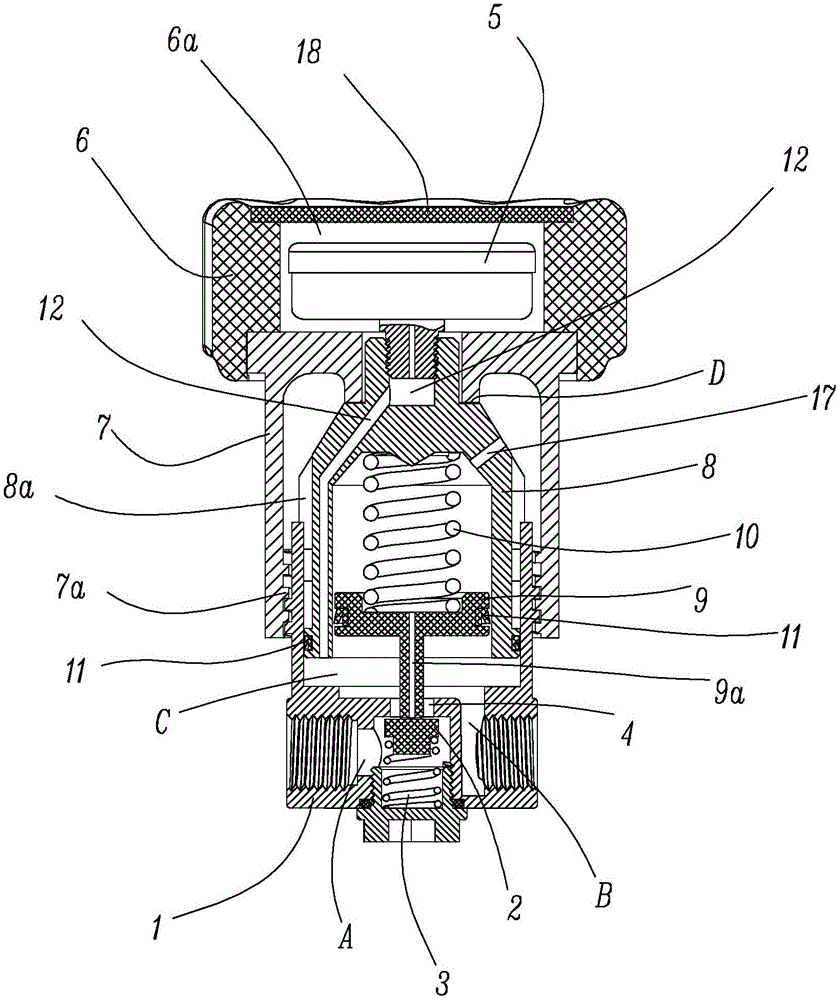

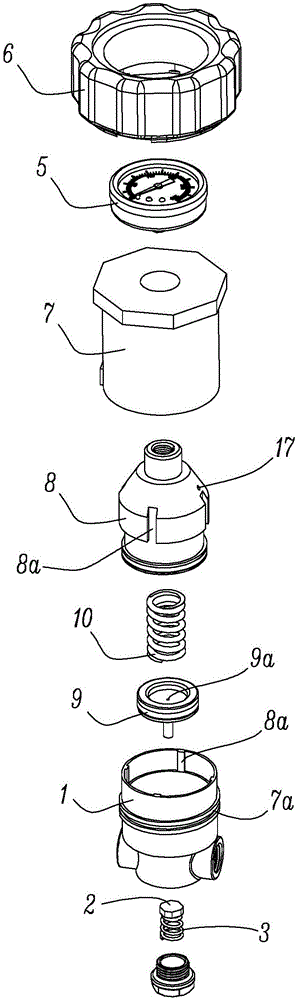

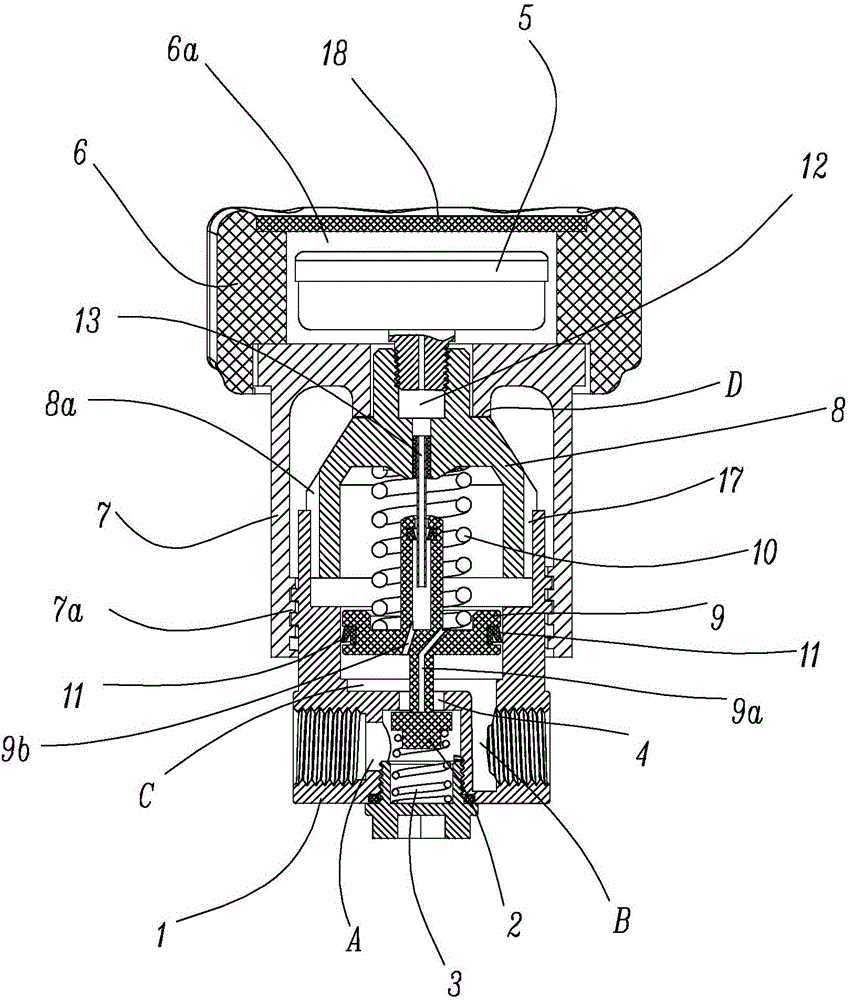

[0041] The present invention will be further described below with specific embodiment, see figure 1 -13:

[0042] A knob-type pressure regulating valve with a pressure gauge, which includes a valve seat body 1, a balance valve core 2 and a balance spring 3, and the valve seat body 1 is provided with an inflow chamber A, an outflow chamber B and a confluence chamber C (Such as figure 1 , image 3 , Figure 5 with Figure 7 shown), wherein a connecting passage 4 is opened between the inflow chamber A and the confluence chamber C, the balance valve core 2 is placed in the valve seat body 1 (such as the inflow chamber A) and its sealing end faces the connection passage 4, that is, the balance spool 2 has a working end used as a sealing function and the working end is arranged to face the connecting channel 4 (see figure 1 , image 3 , Figure 5 with Figure 7 ), the balance spring 3 normally drives the balance spool 2 to create a state of blocking the connecting channel 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com