Detection method of linear grating ruler

A technology of linear grating and detection method, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of relying on manual point-finding measurement results and large influence, and achieve the effect of automatic detection, elimination of influence, and convenient detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0043] The detection method of the linear grating ruler is realized based on the detection device of the one-dimensional linear grating ruler;

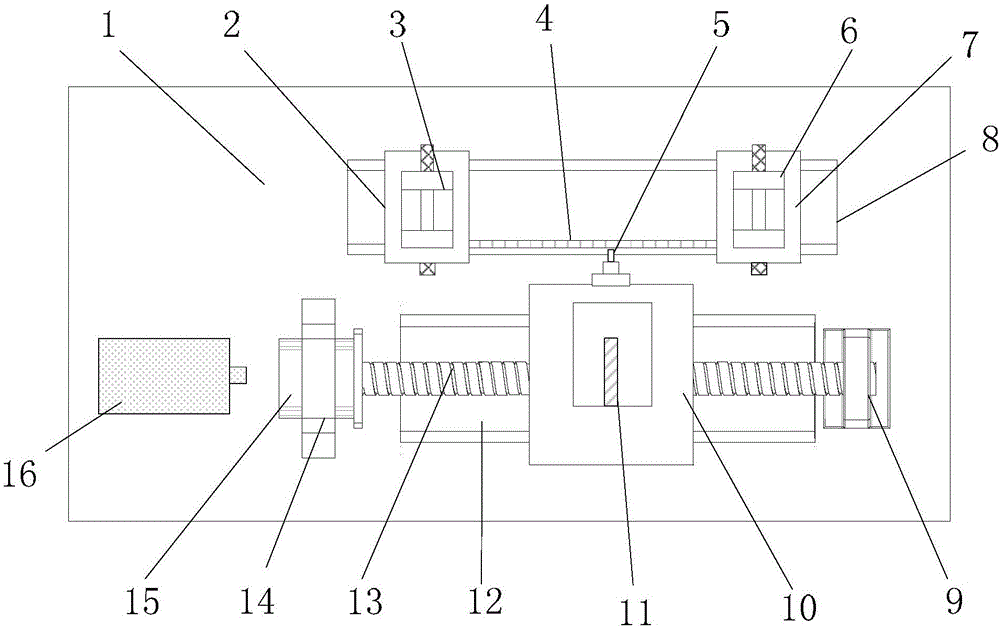

[0044] like figure 1 As shown, the detection device of the one-dimensional linear grating ruler includes a base 1, a displacement reference mechanism, a displacement transmission mechanism and a three-optical axis laser interferometer 16;

[0045] The displacement reference mechanism includes a first clamping slider 2, a first clamping mechanism 3, a second clamping slider 7, a second clamping mechanism 6 and a slider guide seat 8;

[0046] The displacement transmission mechanism includes a motor 15, a ball screw 13, a ball guide seat 12, a ball slider 10, a grating reading head 5, and a bearing seat 9;

[0047] The slider guide seat 8 and the ball guide seat 12 are arranged on the base 1; axis parallel;

[0048] The first clamping slider 2 and the second clamping slider 7 are both arranged on the slider guide seat 8 and can move a...

specific Embodiment approach 2

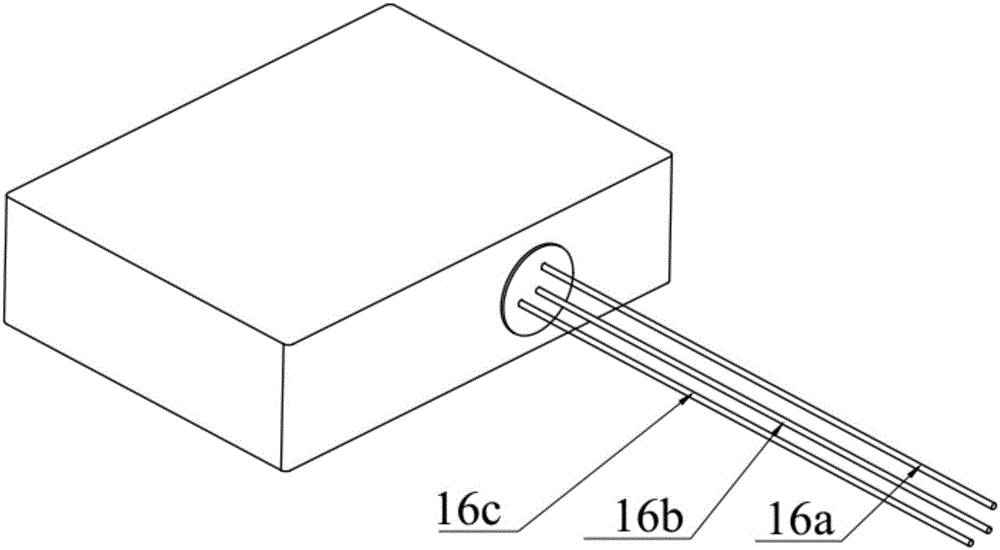

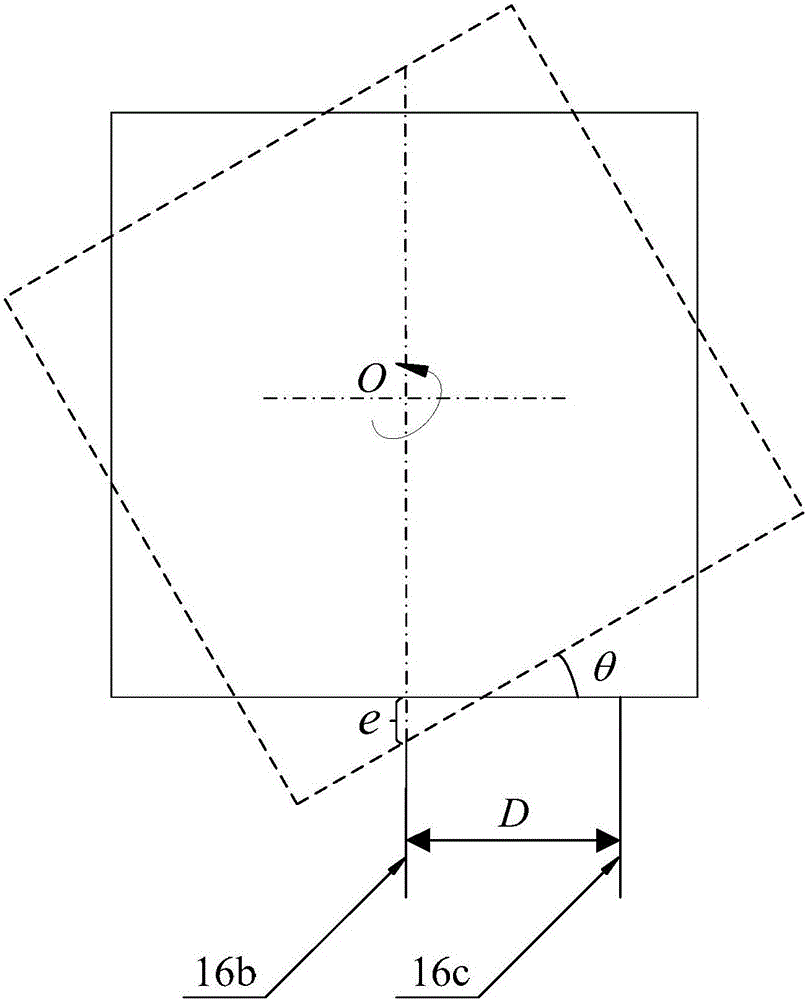

[0071] Specific implementation mode 2: Combining figure 2 and image 3 Describe this embodiment,

[0072] In step 5 of this embodiment, for the i-th measurement point, the displacement values sαi' and sγi' measured by the three-axis laser interferometer are used to compensate sβi' to obtain s i ' The process includes the following steps:

[0073] For the i-th measurement point, the deflection angle is obtained from the distance D between the second beam 16b and the third beam 16c

[0074] Then, according to the distance D and the deflection angle θ, the displacement deviation e on the second beam 16b caused by the deflection is calculated, and then through the formula s i '=sβi'-e compensate sβi' to get s i '.

[0075] Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0077] In the fifth step of this embodiment, e=Dsinθ.

[0078] Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com