Helium gas leakage test process

A helium gas and process technology, applied in the field of helium gas leak test process, can solve the problems of not particularly accurate detection effect, affecting the company's quality performance, and uncontrollable product quality, so as to improve product quality, ensure accuracy, and improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

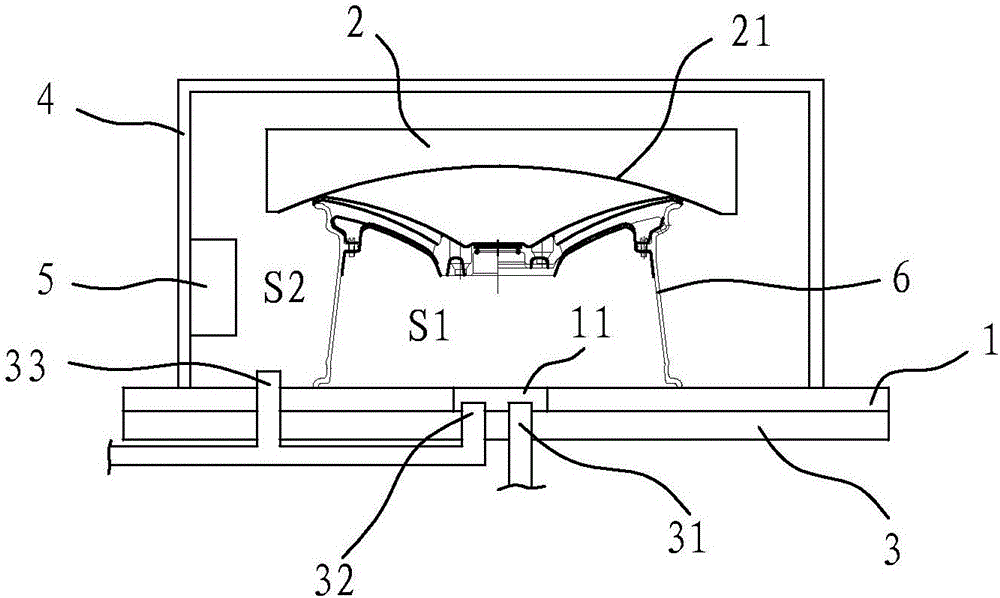

[0028] Such as figure 1 and figure 2 As shown, a kind of helium gas leak test technique that the present invention relates to comprises the following steps:

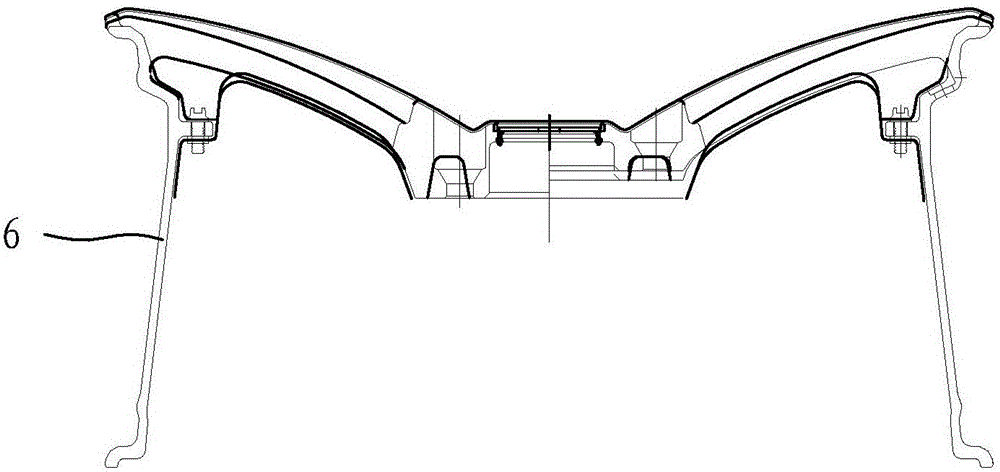

[0029] ① Clean the rim 6 to be tested, dry it after cleaning, and put it into the entrance of the test assembly line;

[0030] ② Driven by the power mechanism, the rims 6 to be tested are transported to the helium test area one by one. The helium test area is equipped with a lower gasket 1, an upper gasket 2, an iron plate 3, an outer cover 4 and an air leakage detection Mechanism 5, a through hole 11 is formed in the middle of the lower gasket 1, the iron plate 3 is located below the lower gasket 1, and the iron plate 3 forms a helium gas filling head 31 and a first vacuum tube 32 at the position corresponding to the through hole 11, A second vacuum tube 33 is also formed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com