Variable cross-section heavy piston compressor

A compressor and variable cross-section technology, applied in the field of wind tunnel testing, can solve the problems of reducing the enthalpy value of the wind tunnel, affecting the pressure stability and attenuation of the wind tunnel nozzle chamber, and reducing the relative displacement and the effective test time of the wind tunnel. Extending and alleviating the effect of shock attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

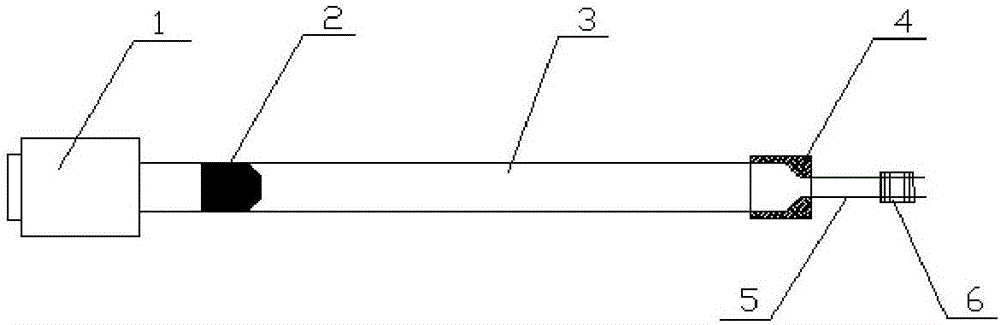

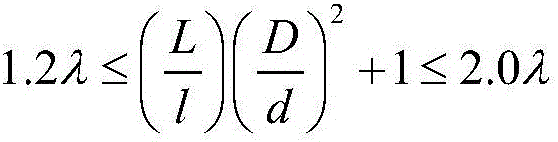

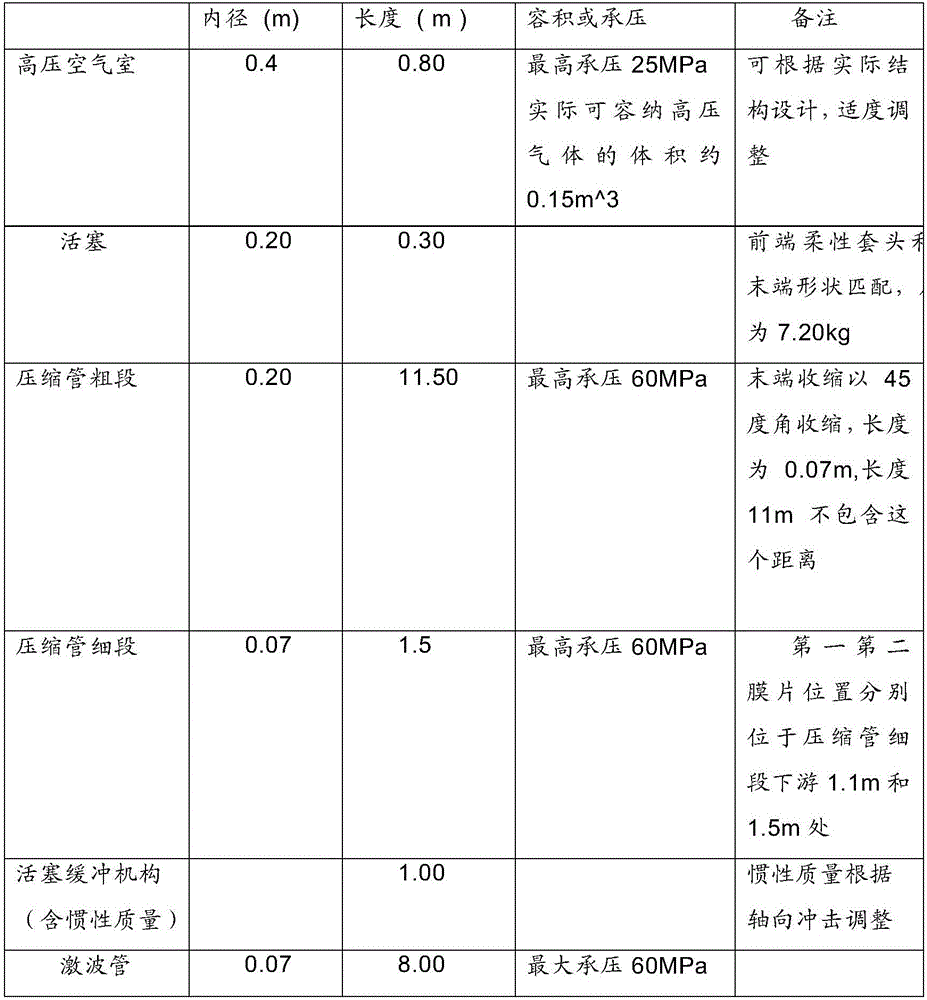

[0033] Taking a certain wind tunnel as an example, this type of piston compressor is briefly explained. The first and second clamping positions of the main diaphragm of the variable cross-section piston compressor are respectively located 1.1 m and 1.5 m downstream of the thin section of the compression tube. When the first position is enabled, the equivalent length of the shrinkage connection section is about 0.035m, and the equivalent length of the thin section of the compression tube is about 0.135m, so the maximum compression ratio is (11.5+0.035+0.135 ) / 0.135≈86.44, when the second position is enabled, the maximum compression ratio that can be obtained is (11.5+0.035+0.184) / 0.184≈63.70. Such redundant processing will increase the deceleration distance of the piston after the diaphragm is opened. The specific parameters of the variable cross-section piston compressor are shown in Table 1.

[0034] Table 1

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com