Light diffusion sheet for overlaying, and backlight unit

A light diffusion sheet and backlight unit technology, applied in the direction of optical components, light guides, optics, etc., can solve the problems of slight roughness, unevenness, roughness, etc., and achieve the effect of suppressing flickering and uneven brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

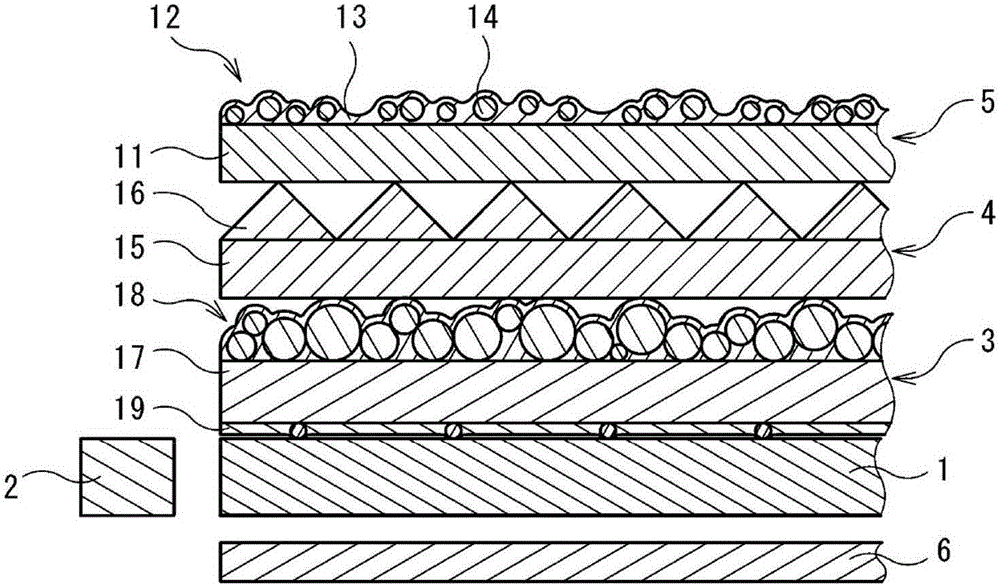

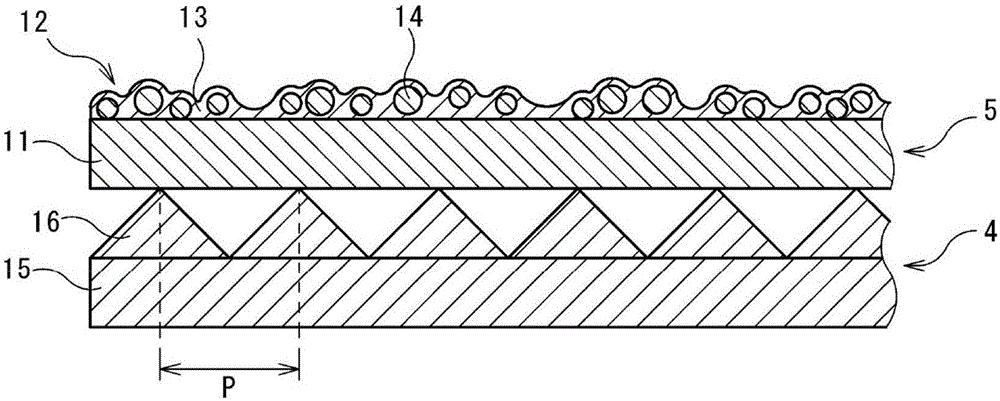

[0153] In addition, the light-diffusion sheet for top use of this invention, and a backlight unit can also be implemented in the aspect which modified and improved variously besides the said form. For example, the backlight unit may include another optical sheet other than the upper light diffusion sheet, the prism sheet, and the lower light diffusion sheet on the surface side of the light guide sheet. In addition, the backlight unit does not necessarily have to be an edge-type backlight unit, and may be, for example, a direct-type backlight unit in which a diffusion plate and a light source are arranged on the back side of a lower light-diffusing sheet.

[0154] The specific structures of the prism sheet, the light diffusion sheet, the light guide sheet, the light source and the reflection sheet of the backlight unit are not particularly limited, and members of various structures can be used.

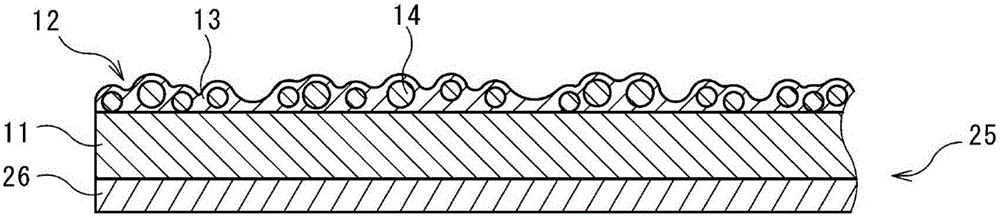

[0155] The above light diffusion sheet is preferably a two-layer structure of a ba...

Embodiment 1

[0160] On the surface of a substrate layer with an average thickness of 75 μm mainly composed of polyethylene terephthalate, a light-diffusing layer in which resin beads are dispersed in a resin matrix mainly composed of an ultraviolet curable resin is laminated, thereby The top light-diffusing sheet of Example 1 was produced. As the resin beads, resin beads obtained by mixing first beads having a larger average particle diameter and second beads having a smaller average particle diameter than the first beads at a ratio of 2:1 (mass ratio) were used. In addition, the lamination amount of the light-diffusing layer is 2.5 g / m 2 The content rate of the resin matrix of the light-diffusion layer was 66.61 mass %, and the average thickness of the said light-diffusion layer was 3.5 micrometers. in addition, Figure 6 It is a partially enlarged cross-sectional photograph of the top light-diffusing sheet of Example 1.

Embodiment 2

[0162] Except having made content of the resin matrix of a light-diffusion layer into 52.57 mass %, it carried out similarly to Example 1, and manufactured the top light-diffusion sheet of Example 2. The average thickness of the light diffusion layer is 3.7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Arithmetic mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com