TFT liquid crystal display assembly method and system based on six-axis manipulator platform

A six-axis manipulator and assembly method technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of large manual assembly errors, many stations, low efficiency, etc., to reduce scrap rate, improve production efficiency and yield. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

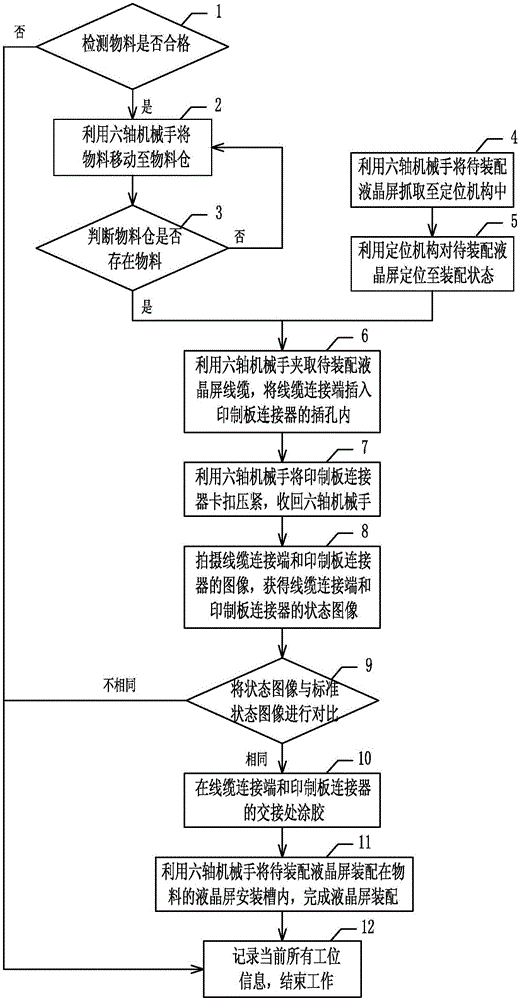

[0041] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, the method for assembling a TFT liquid crystal screen based on a six-axis manipulator platform described in this embodiment includes the following steps:

[0042] Step 1: Check whether the material is qualified, if yes, perform step 2, otherwise, perform step 12, the material is an automobile combination instrument without an LCD screen,

[0043] Step 2: Use the six-axis manipulator to move the material to the material bin, and then perform step 3,

[0044] Step 3: Determine whether there are materials in the material bin, if yes, perform step 6, otherwise return to step 2,

[0045] Step 4: Use the six-axis manipulator to grab the LCD screen to be assembled into the positioning mechanism, and then perform step 5,

[0046] Step 5: Use the positioning mechanism to position the liquid crystal screen to be assembled to the assembly state, and then perform step 6. The assembly state i...

specific Embodiment approach 2

[0055] Specific embodiment two: This embodiment is to further explain the TFT liquid crystal screen assembly method based on the six-axis manipulator platform described in specific embodiment one. In this embodiment, a photoelectric sensor is used in step 3 to determine whether there is material in the material bin. .

specific Embodiment approach 3

[0056] Embodiment 3: This embodiment is to further explain the TFT liquid crystal screen assembly method based on the six-axis manipulator platform described in Embodiment 1. In this embodiment, in step 6, first set the insertion depth in the electric cylinder , and then insert the cable connection end into the socket of the printed board connector according to the set insertion depth.

[0057] This embodiment can ensure that the plug accurately reaches the insertion depth, avoids the problem of manual insertion not in place, and further reduces the risk of the cable falling off during the driving of the car.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com