An intelligent press-fitting system based on high-end manufacturing and process monitoring

A process monitoring and intelligent technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problem of difficult to achieve full closed-loop control, inability to monitor the subtle changes of the press-fitting force-displacement curve, and difficult to achieve precise press-fitting control. and monitoring and other issues to achieve the effect of lean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

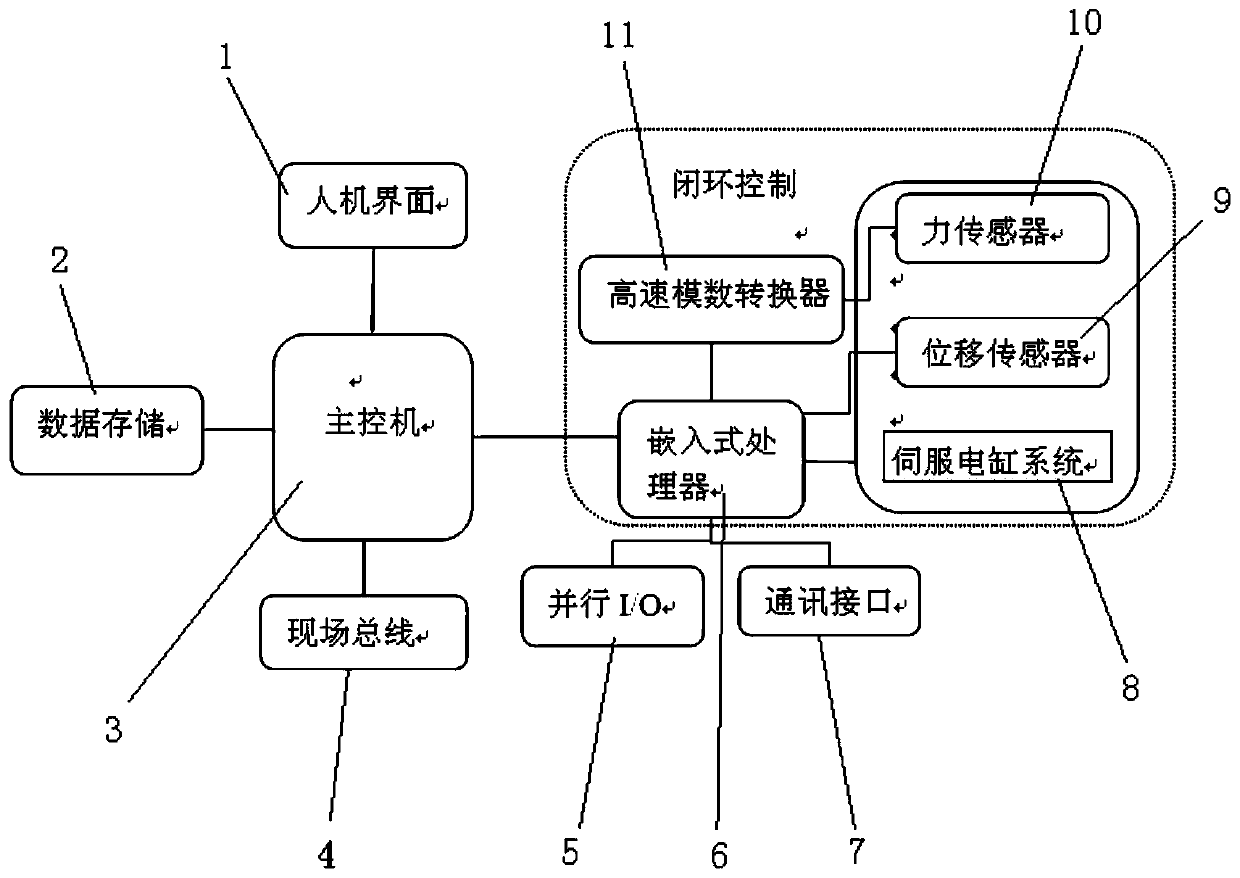

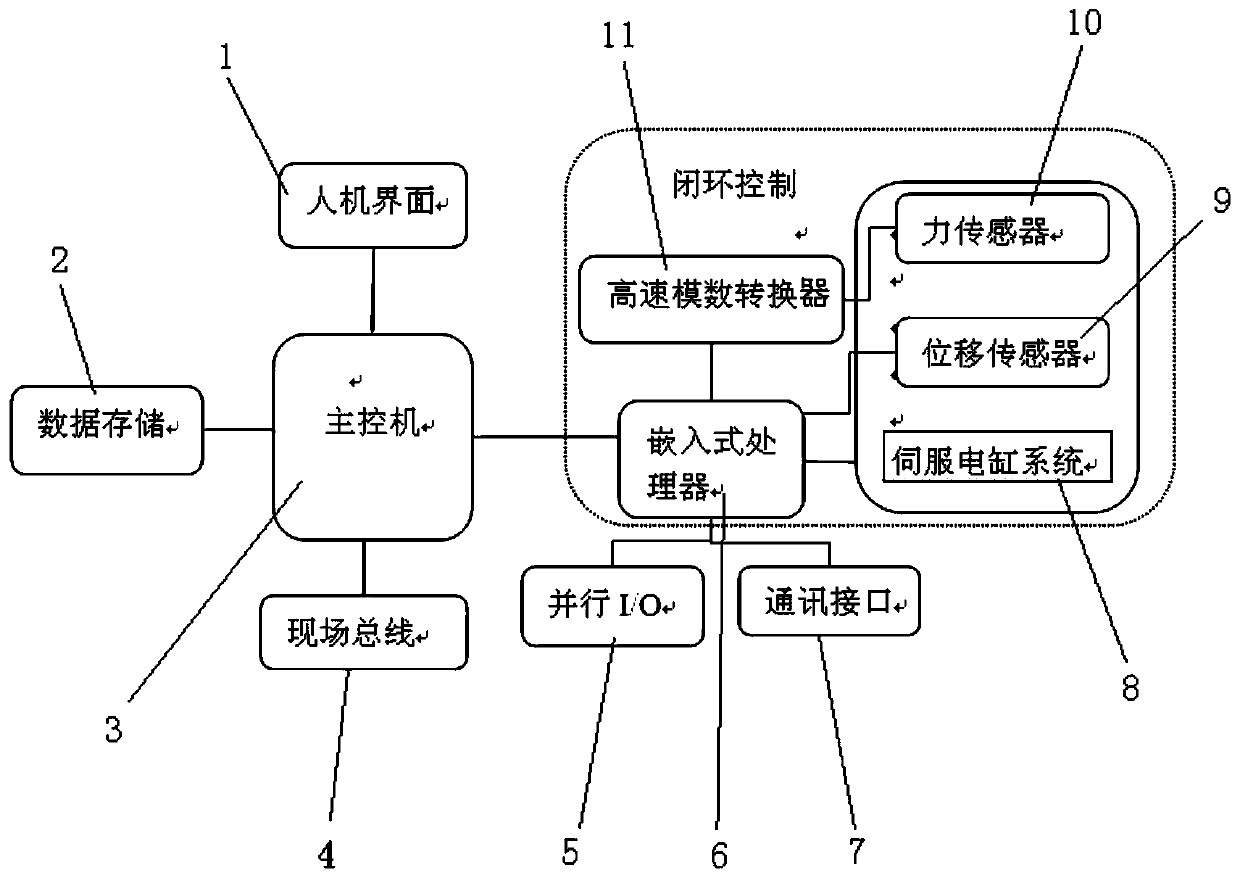

[0028] see figure 1 , the equipment mainly includes force sensor 10, displacement sensor 9, high-speed analog-to-digital converter 11, servo electric cylinder system 8, high-performance embedded processor 6, parallel output and input interface 5, communication interface 7, main control machine 3, man-machine Interface 1, data storage 2, field bus 4 and other units.

[0029] The system of the main control machine 3 adopts the IMX6Q processor with ARM A9 architecture. The core board mainly includes the central processing unit IMX6Q, 4G Flash, and 2G RAM. .34. The master computer runs operating systems such as Windows, Linux or Android. The main control computer software is developed with C++, which can realize parameter setting such as limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com