Project plan management system and method, and computer storage medium

A project planning and management system technology, applied in the field of project planning management system, can solve the problems of increasing costs, storage space storage, etc., and achieve the effects of controlling costs, realizing standardization, and avoiding untimely replenishment of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

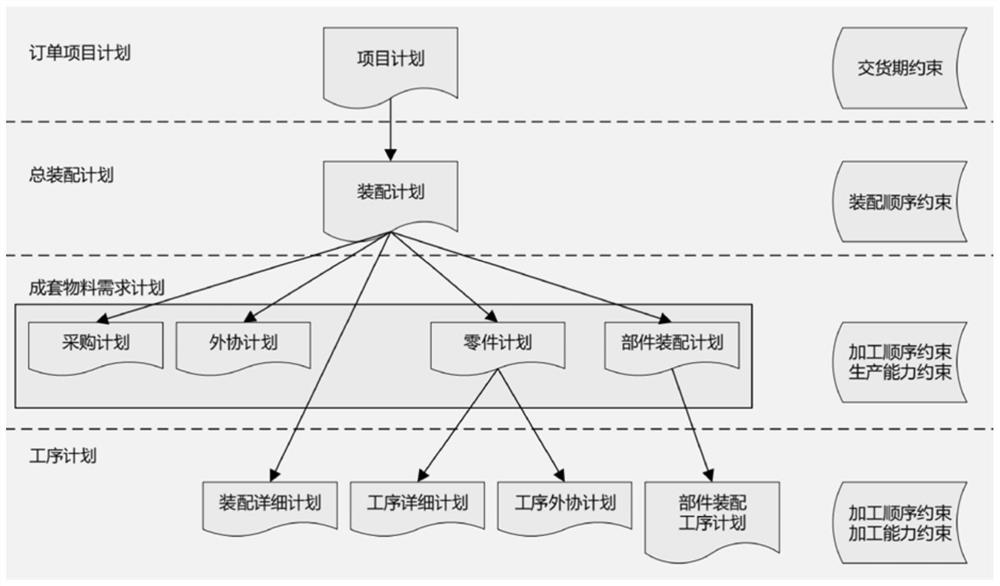

[0053] Embodiment 1. Combining figure 1 and 2 Describe this implementation mode, this implementation mode provides a project plan management system, and the described system includes:

[0054] Project planning unit, used to prepare product project plans according to orders;

[0055] The general assembly planning unit is used to prepare the product general assembly plan according to the product project plan;

[0056] The complete set of material requirement unit is used to prepare the product complete set of material requirement plan according to the general assembly plan of the product;

[0057] The process planning unit is used for preparing a product process plan according to the product general assembly plan.

[0058] Specifically, the project plan management system provided by this embodiment is a project plan prepared according to the order, so the project plan meets the requirements of the quality and acceptance time of all components in the order;

[0059] The gener...

Embodiment approach 2

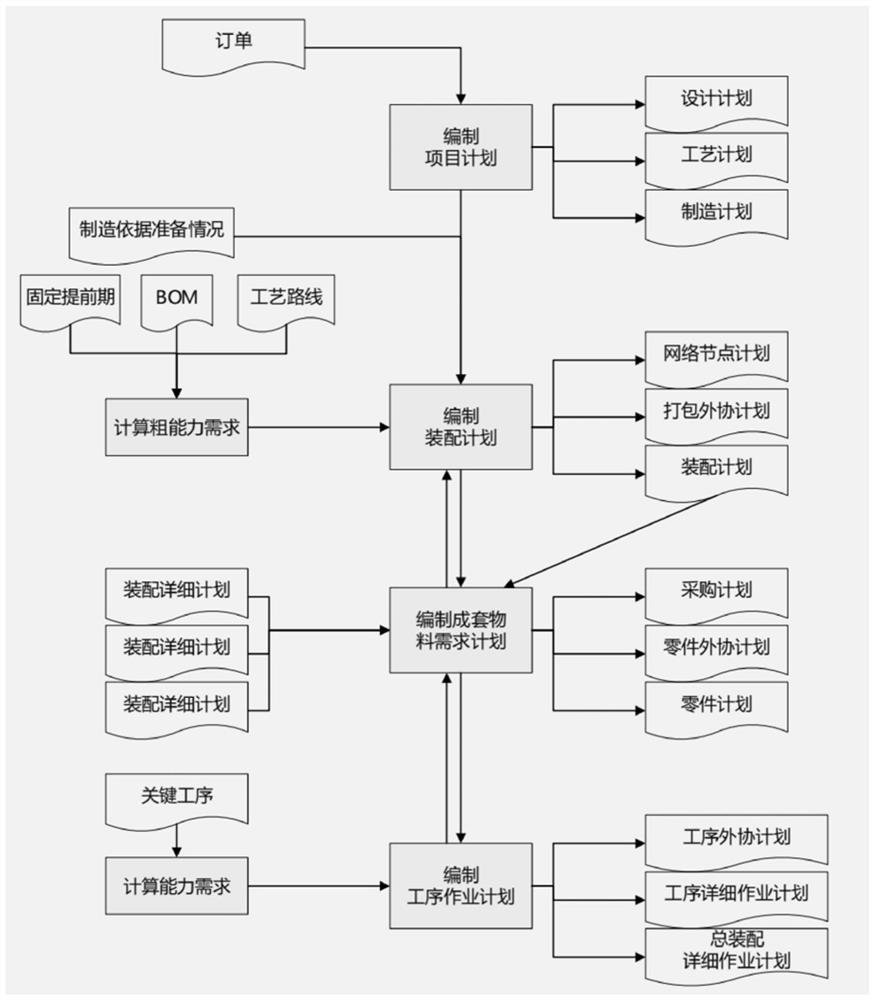

[0064] Embodiment 2. Combination figure 1 and 2 Describe this embodiment. This embodiment is a further limitation of the project plan management system provided by Embodiment 1. The project plan unit includes:

[0065] A design planning module, used for preparing a product design plan according to the order;

[0066] A process planning module, used for preparing a product process plan according to the order;

[0067] The manufacturing planning module is used for preparing a product manufacturing plan according to the order.

[0068] Among them, the project planning unit decomposes the project plan according to the product according to the content in the order, and decomposes it into: product design plan, for specific parts of non-standard products and parts that have not been manufactured before, prepare design plan, limit the start of part design and The end time; product process plan, to prepare the plan of the entire process flow of the product; product manufacturing pla...

Embodiment approach 3

[0069] Embodiment 3. Combination figure 1 and 2 Describe this embodiment. This embodiment is a further limitation of the project plan management system provided in Embodiment 1. The preparation of the product assembly plan meets the crude capacity requirements, and the crude capacity requirements include: the lead time of the actual product , BOM and process route.

[0070] Among them, the judgment condition of rough capacity is that before the preparation of the general assembly plan, the production capacity of the entire workshop is considered to ensure that the prepared plan conforms to the actual production capacity, so as to effectively ensure that the project is completed on schedule according to the plan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com