Method for verifying damage mechanisms of high-temperature resistant composite-material structure under multiple failure modes

A composite material and verification method technology, which is applied in the field of multi-failure mode damage mechanism verification of high temperature resistant composite material structures, can solve the problems of high cost, low simulation verification accuracy, can not truly reflect the structural design level, etc., to reduce the verification period and cost, the effect of improving the verification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] with [0] 16 Taking the life test of the fabric one-way plate under the tension-tension fatigue load as an example, the implementation process of the present invention is briefly described.

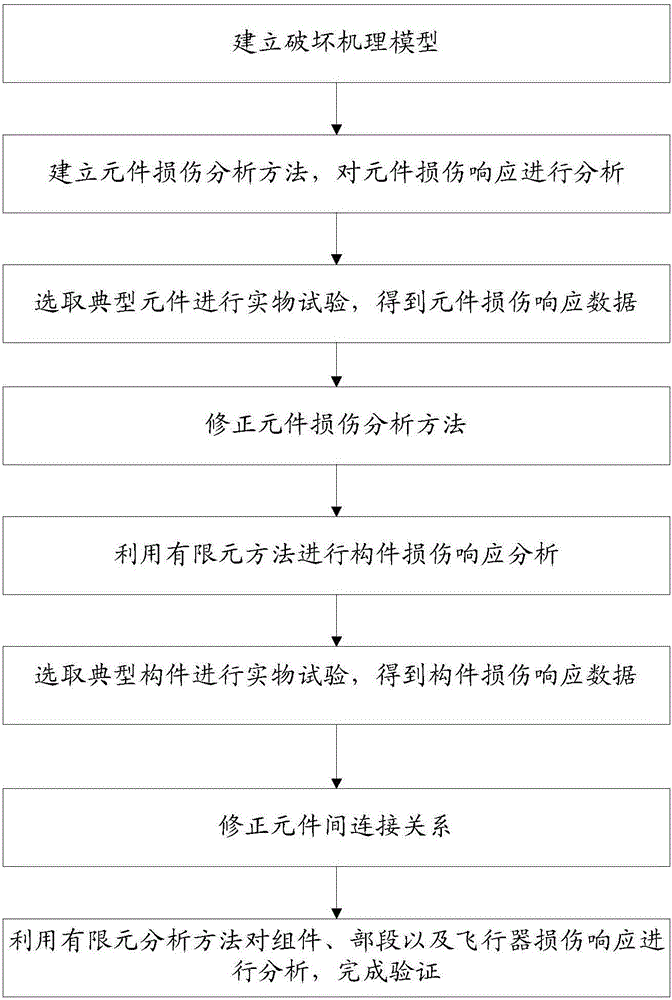

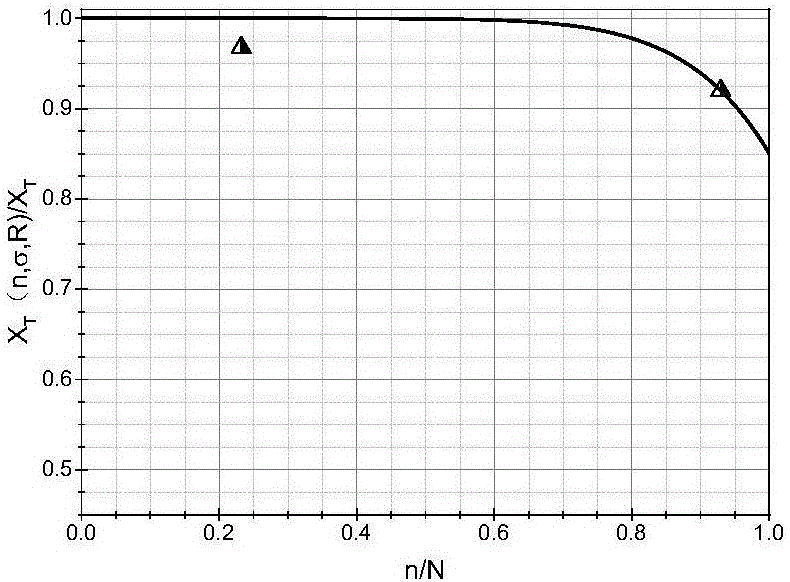

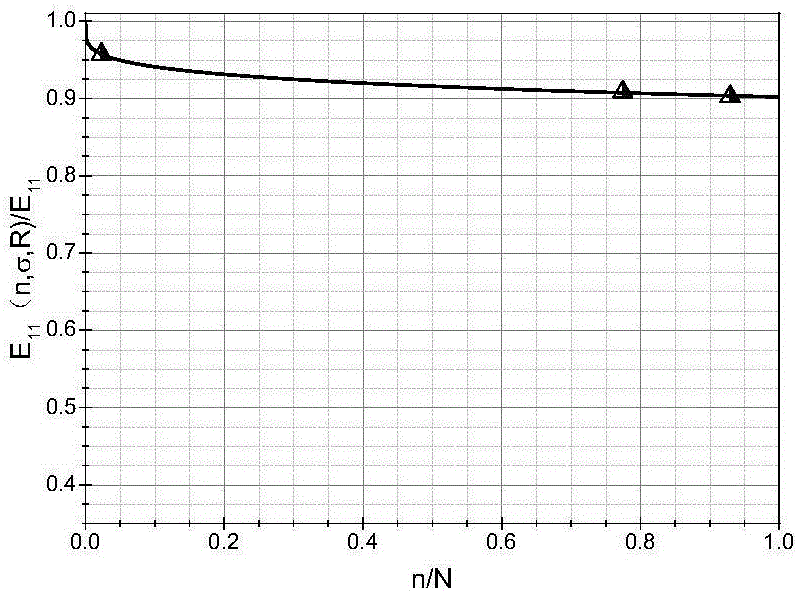

[0124] Select 85% loading as [0] 16 Fixed values of fatigue loads for strength and stiffness degradation tests of fabric unidirectional plates. Adopt the component damage analysis method that the present invention provides to analyze component damage response, obtain [0] 16 The strength degradation curve of fabric unidirectional plate is as follows: figure 2 As shown, the change trend of residual stiffness under different cycle times is as follows image 3 shown. in figure 2 The middle ordinate is [0] 16 The ratio of the residual tensile strength of the fabric unidirectional panel to the static load tensile strength under the specified number of cycles X T (n,σ,R) / X T , and the abscissa is the ratio of loading times to fatigue life (n / N). image 3 The middle ordinate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com