Low-brightness high-gray high-display LED manufacturing process

A manufacturing process, high gray technology, applied in the direction of static indicators, instruments, electrical components, etc., can solve the problems of low display contrast, glare and reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

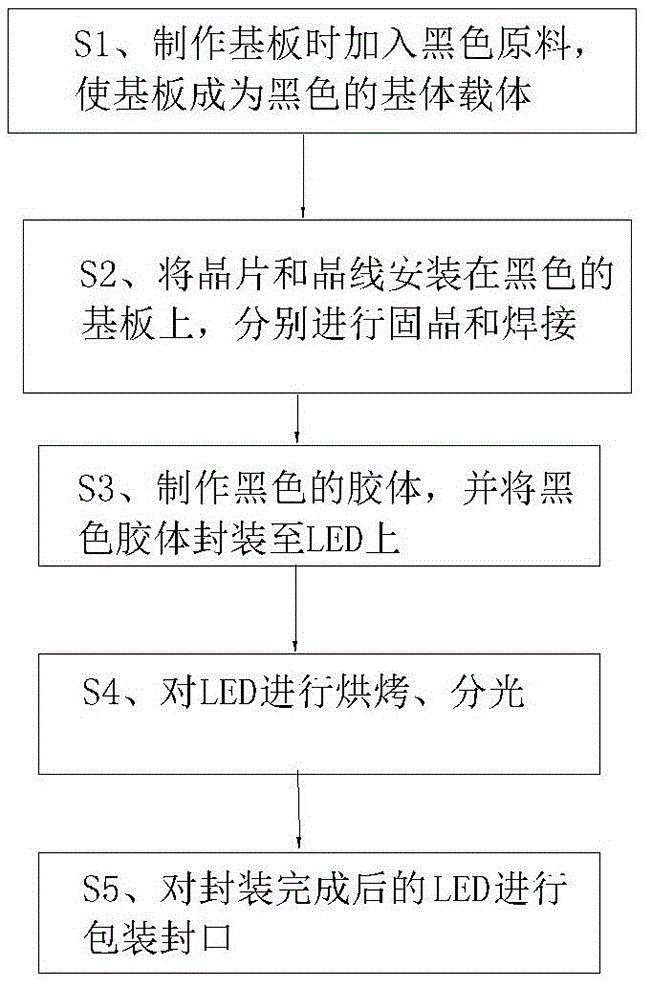

[0020] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0021] refer to figure 1 , a low-brightness, high-gray, high-display LED manufacturing process provided by the present invention comprises steps:

[0022] S1. Add black raw materials when making the substrate, so that the substrate becomes a black matrix carrier;

[0023] S2, install the chip and the crystal wire on the black substrate, and carry out crystal bonding and welding respectively;

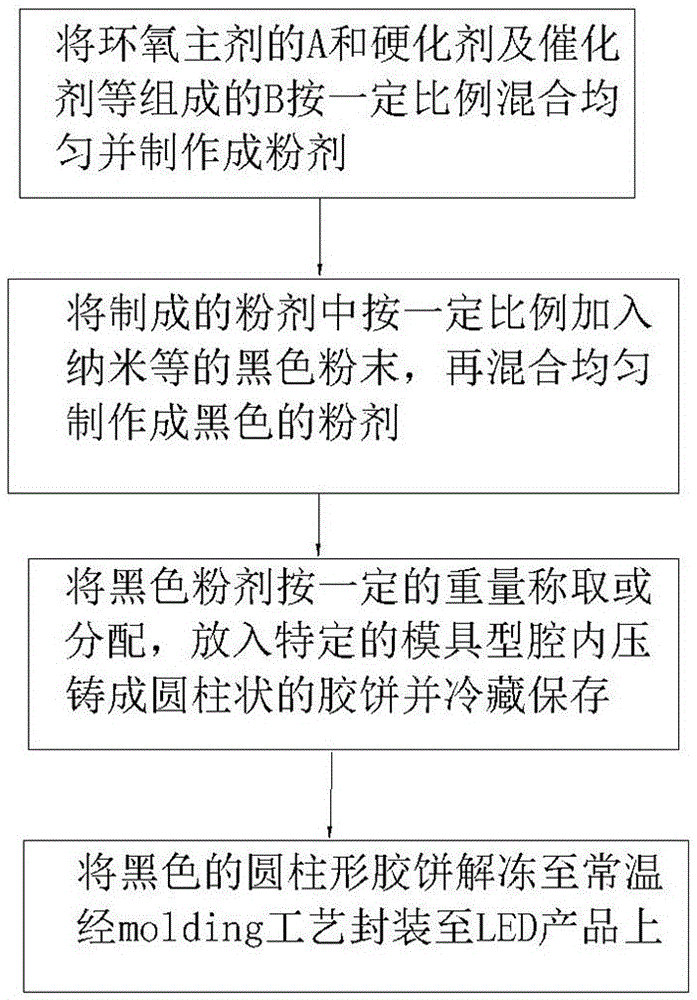

[0024] S3, making black colloid, and encapsulating the black colloid on the LED;

[0025] S4, baking and splitting the LED;

[0026] S5. Packaging and sealing the LED after packaging.

[0027] Compared with the prior art, the low-brightness, high-gray and high-display LED manufacturing process provided by the present invention adopts an all-black manufacturing design, so that the front side of the LED light is completely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com