Patents

Literature

44results about How to "Not easy to drop crumbs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

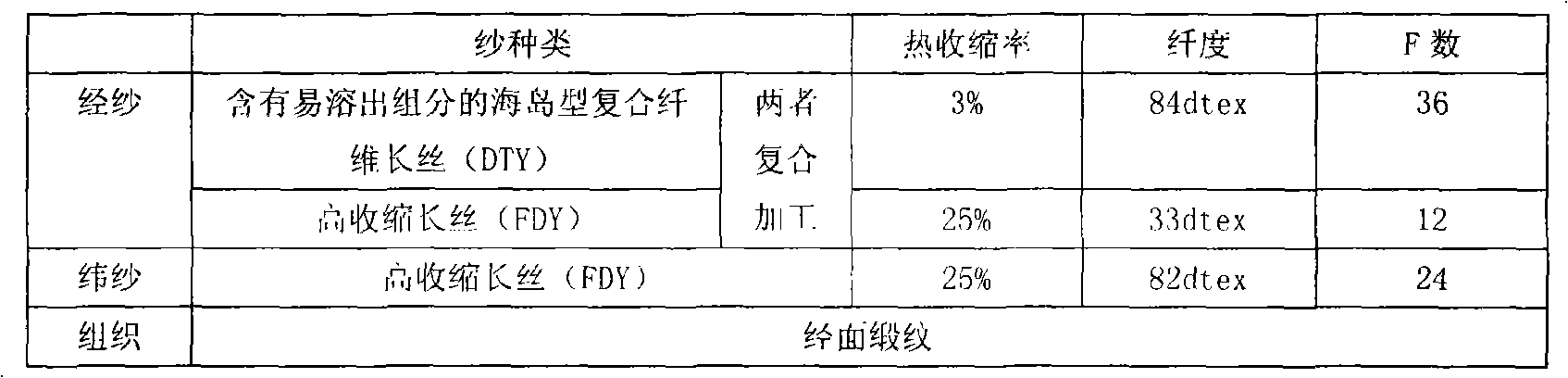

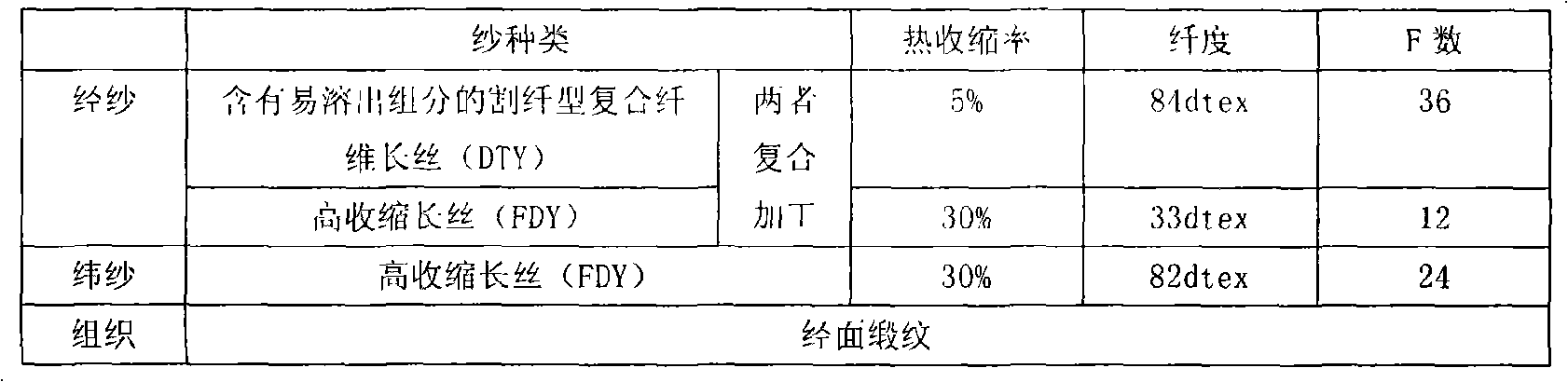

High performance wiping fabric and manufacturing method thereof

InactiveCN101328640AImprove wiping effectNot easy to drop crumbsCarpet cleanersFloor cleanersYarnPolyester

The invention discloses a high-performance wiping textile fabric and a manufacturing method thereof. At least one between wrap and weft which form the textile fabric is composite yarns which are formed by superfine polyester long fibers and modified polyester long fibers, and the corresponding wrap or the corresponding weft is modified polyester long fibers; and the two fibers which form the composite yarns have 5 to 30 percent of yarn length difference, and the fibers with long yarn length is positioned on the surface layer of a wiping surface. The manufacturing method comprises the following steps of: yarn selection, weaving, hot water treatment, splitting, heat-setting and so on. The product of the high-performance wiping textile fabric does not generate dust and has soft hand feeling, good size stability, superior liquid-absorbing property and superior wiping effect. The high-performance wiping textile fabric can be widely applied in assembly of semiconductors, laboratories, electronic industry, manufacture of optical instruments, precise components such as LCD liquid crystal displays and so on, glass articles, clean room environment and so on, and can be also cut into strip roll wipers with various specifications and be matched with automatic wiping devices for use.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

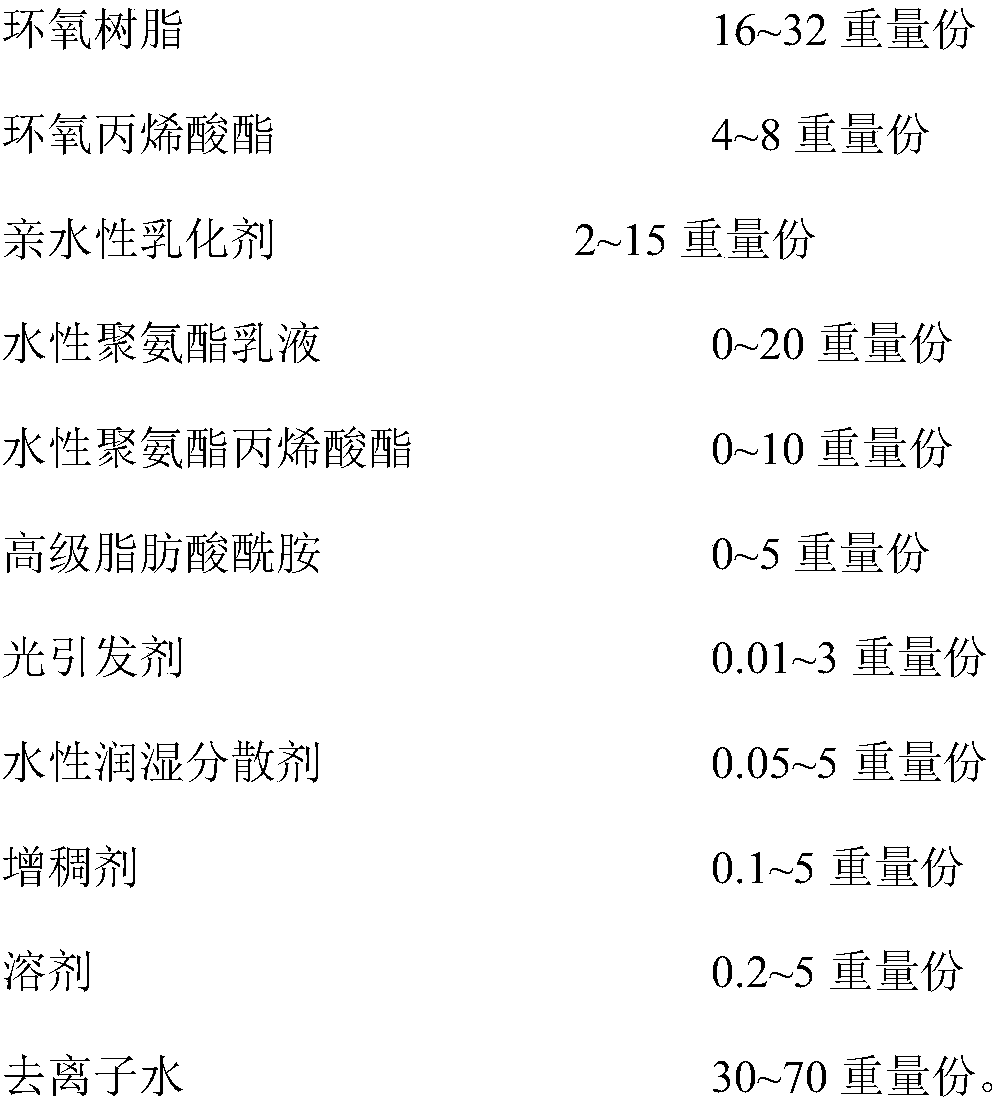

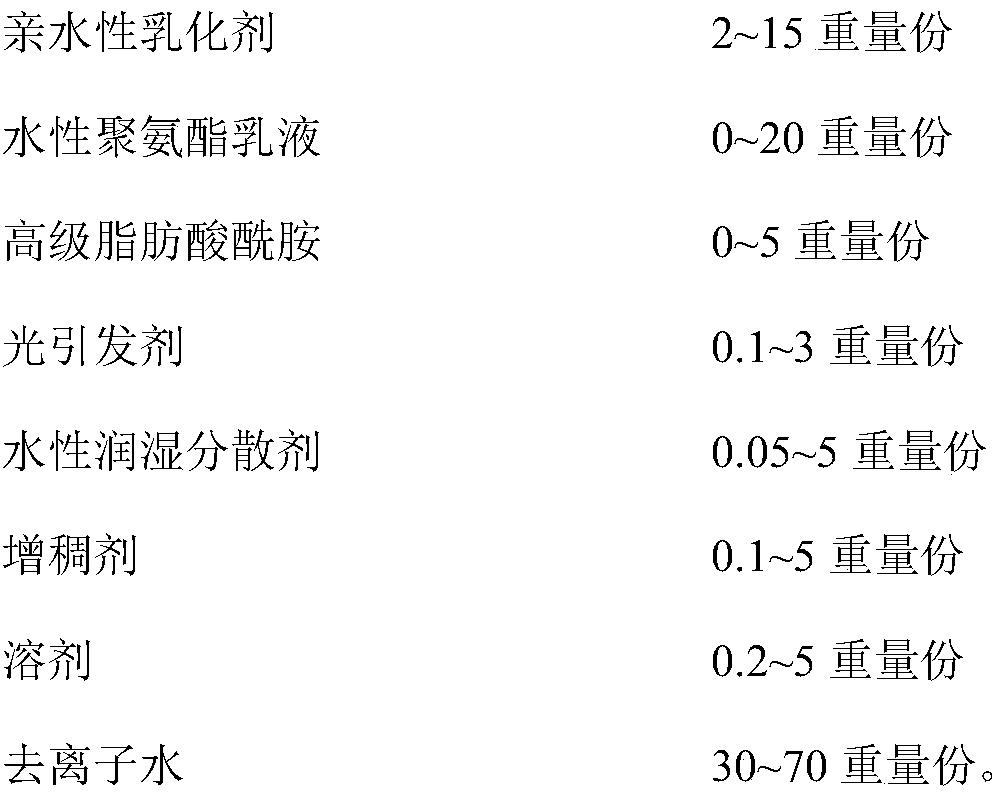

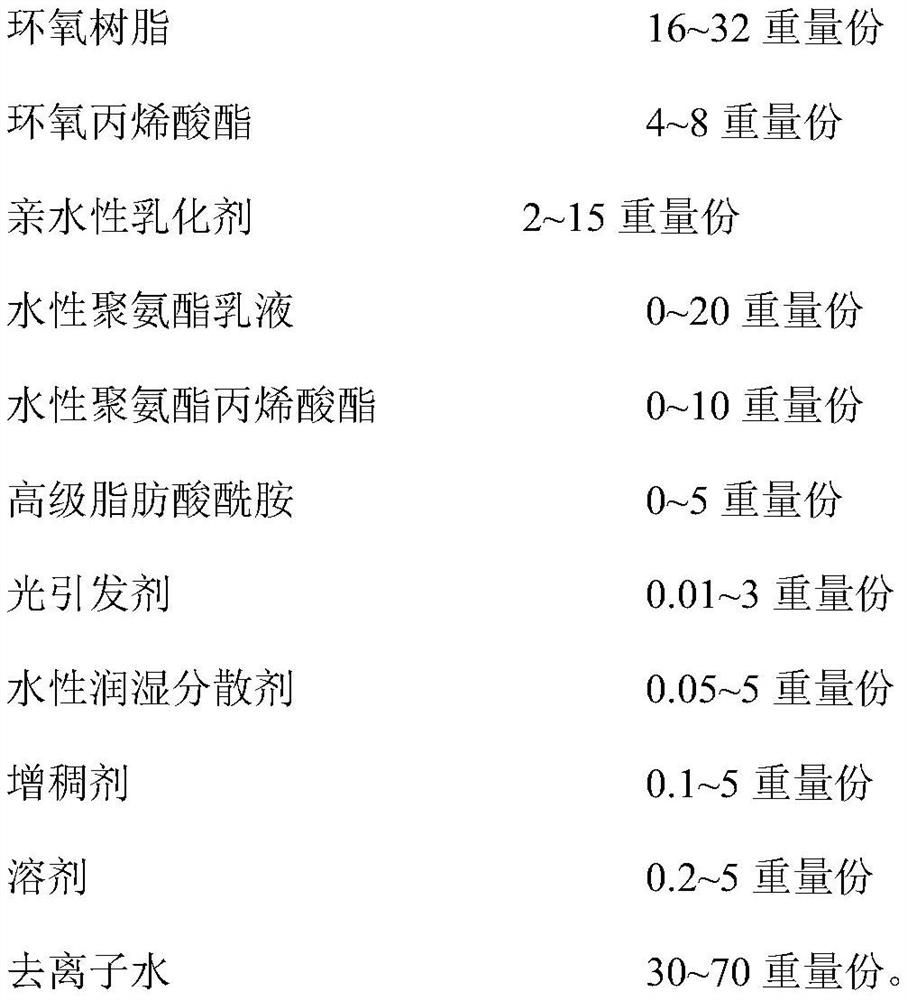

A waterborne carbon fiber sizing agent and a preparing method thereof

ActiveCN109385899AImprove performanceIncrease productivityCarbon fibresGrip property fibresEpoxyCarbon fibers

A waterborne carbon fiber sizing agent and a preparing method thereof are disclosed. The sizing agent is prepared from, by weight, 16-32 parts of epoxy resin, 4-8 parts of epoxy acrylate, 2-15 parts of a hydrophilic emulsifier, 0-20 parts of aqueous polyurethane emulsion, 0-10 parts of aqueous urethane acrylate, 0-5 parts of higher fatty acid amide, 0.01-3 parts of a photoinitiator, 0.05-5 parts of an aqueous wetting and dispersing agent, 0.1-5 parts of a thickening agent, 0.2-5 parts of a solvent and 30-70 parts of deionized water. The sizing agent is a waterborne carbon fiber sizing agent combining heat-curing and photo-curing. Carbon fibers sized by the sizing agent can be dried through a high-temperature drying manner and then cured through a photo-curing manner so that the performanceof the sizing agent is further improved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

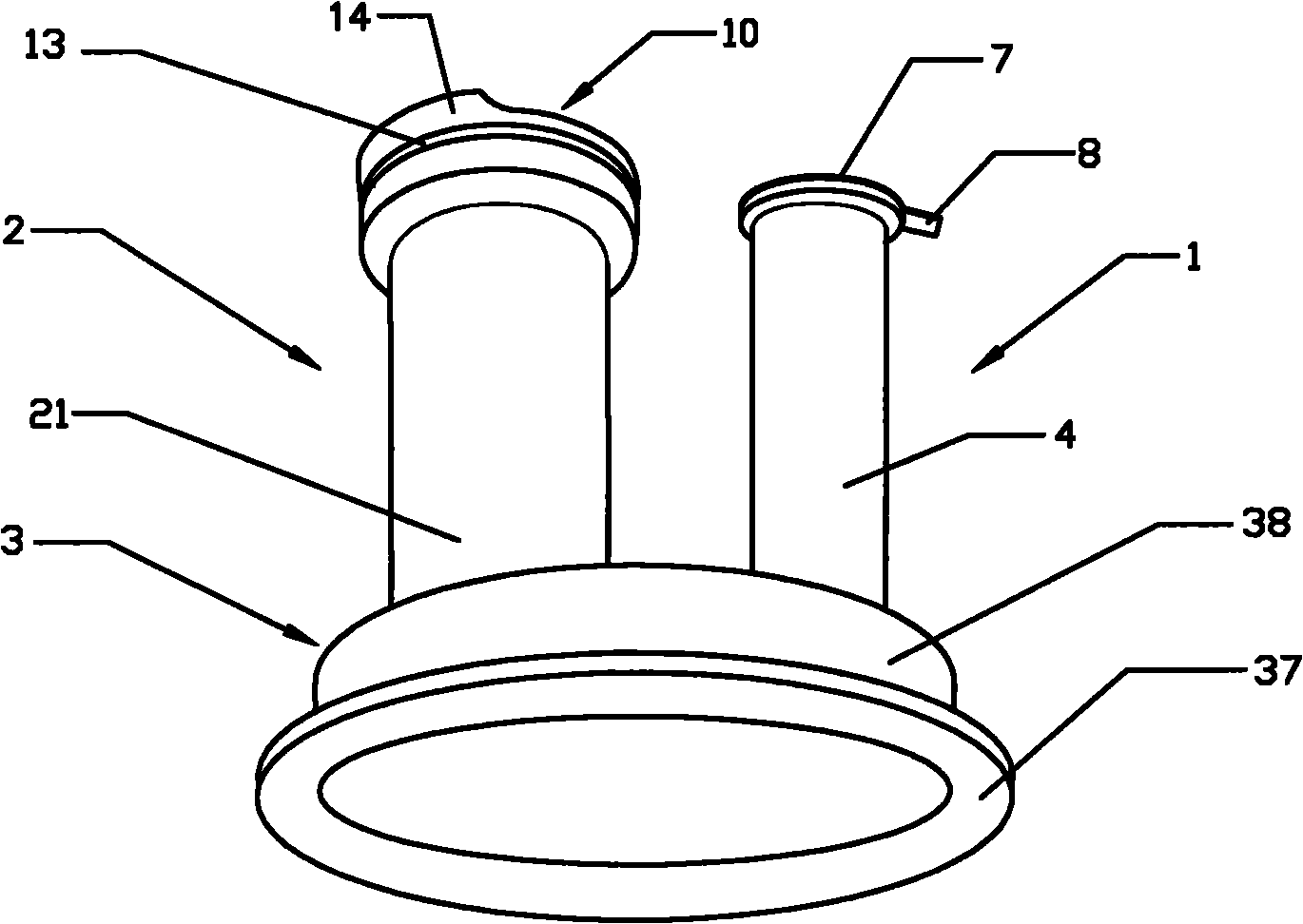

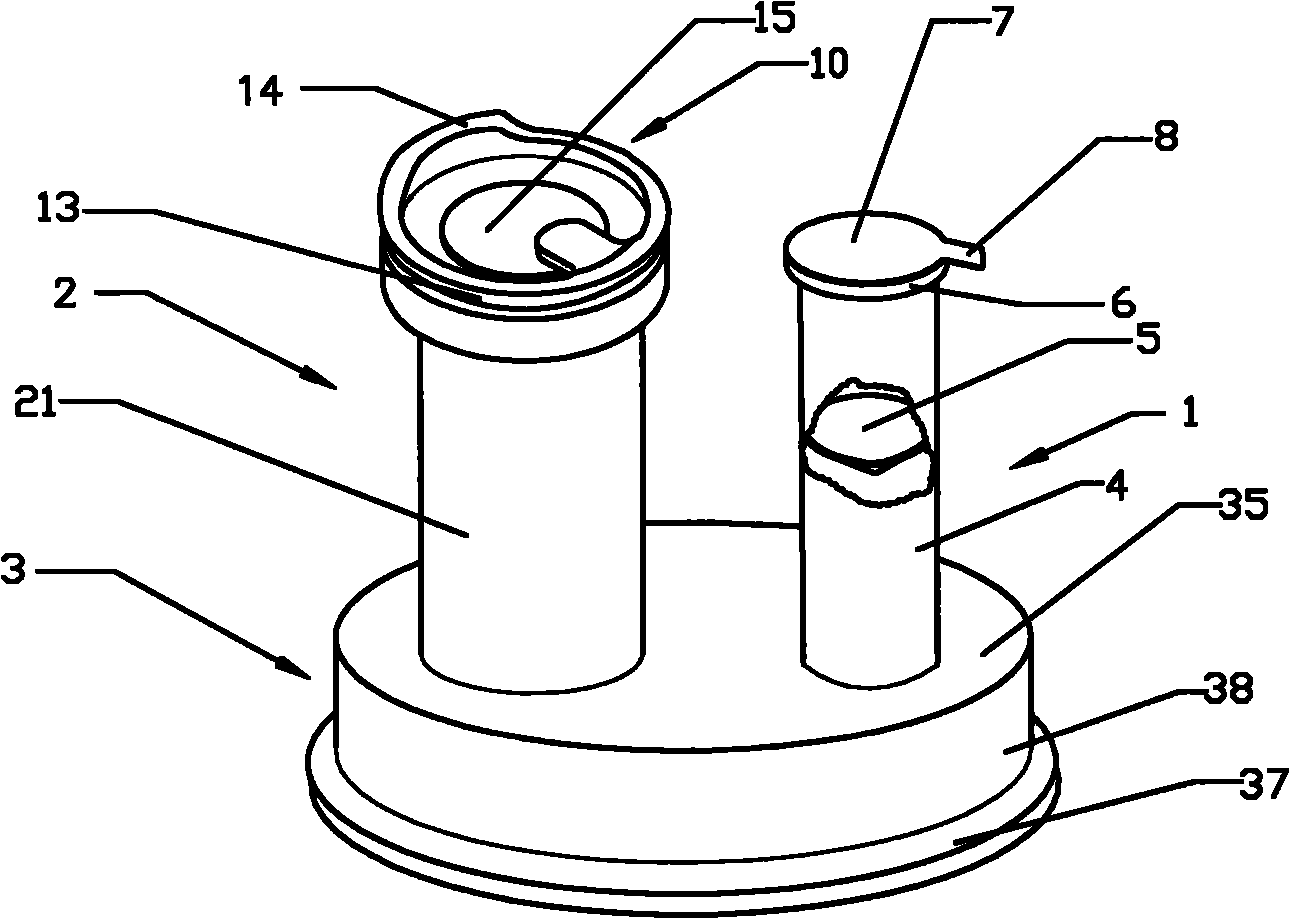

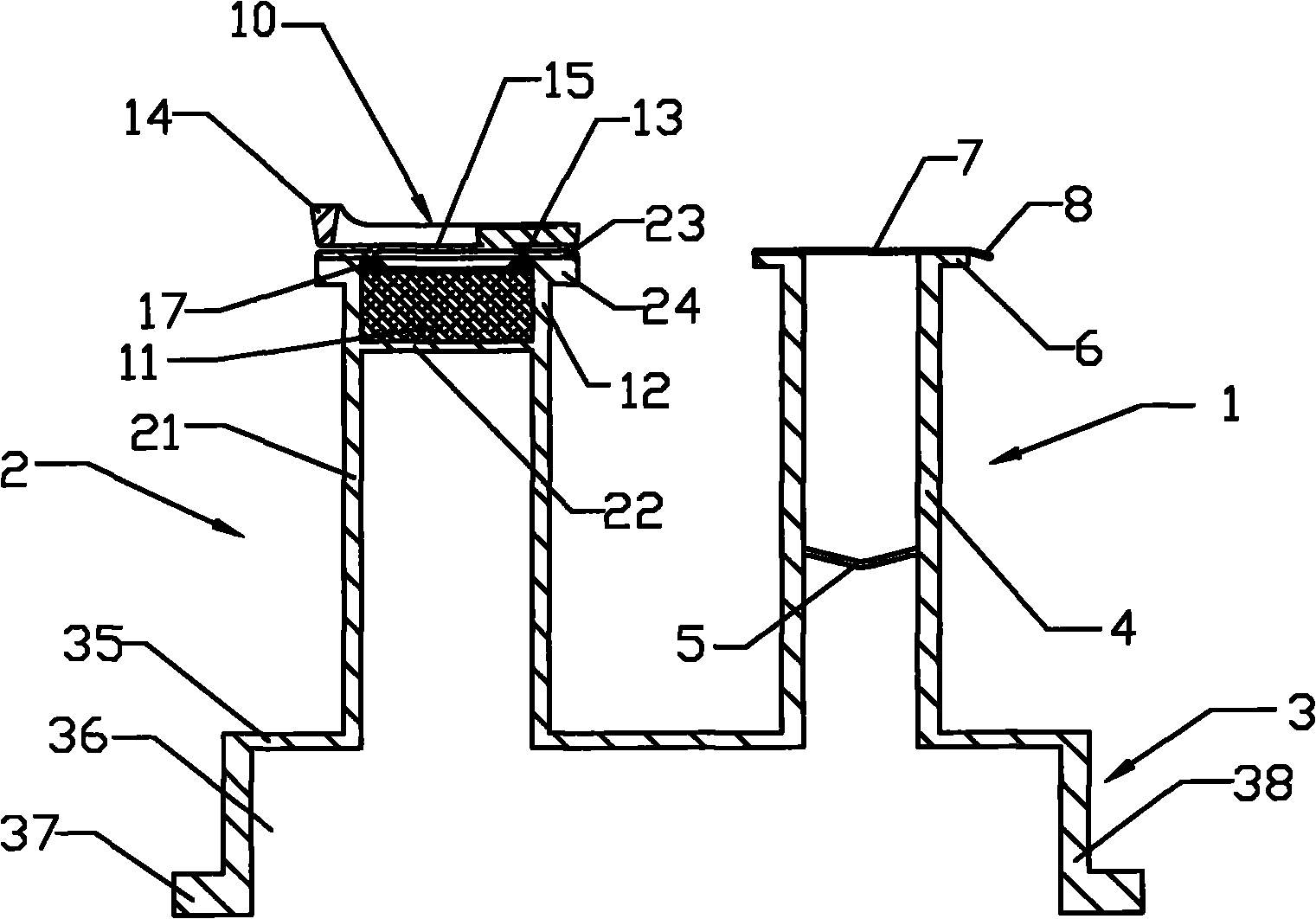

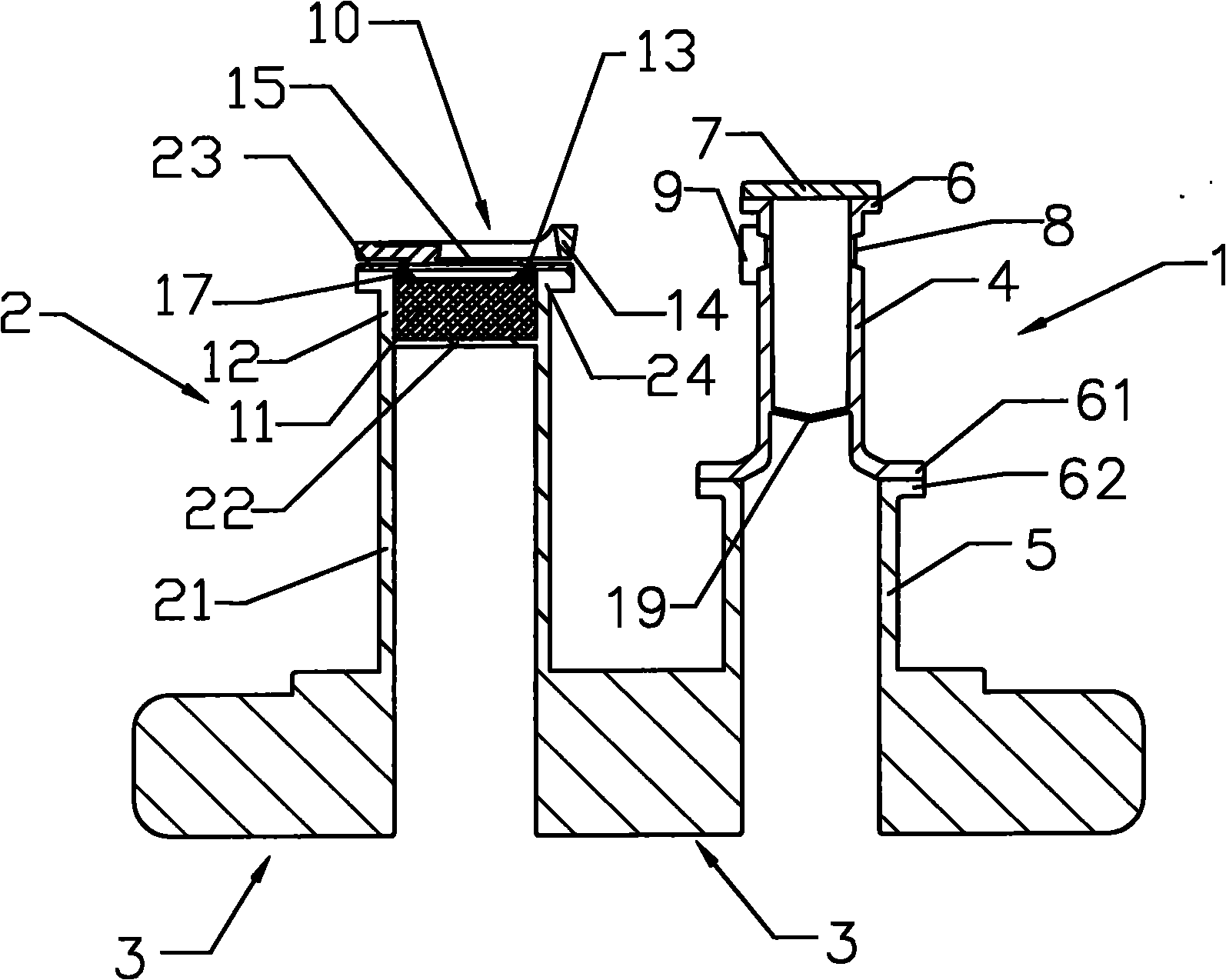

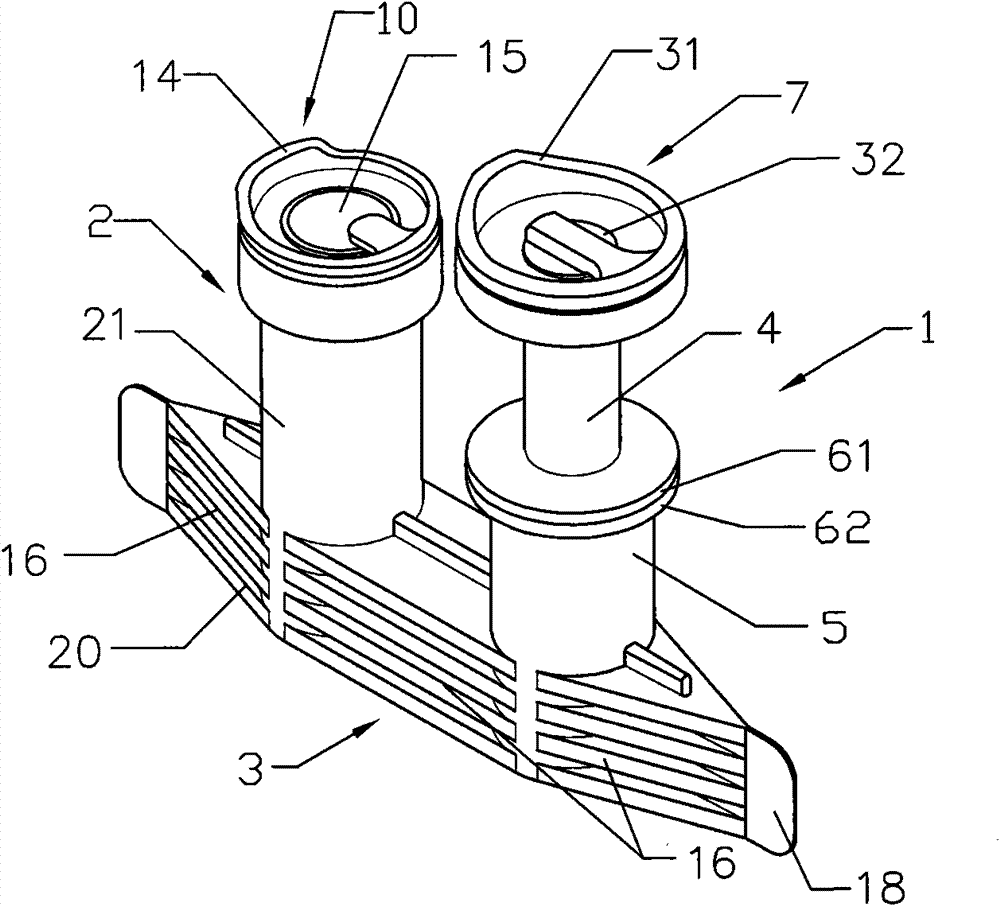

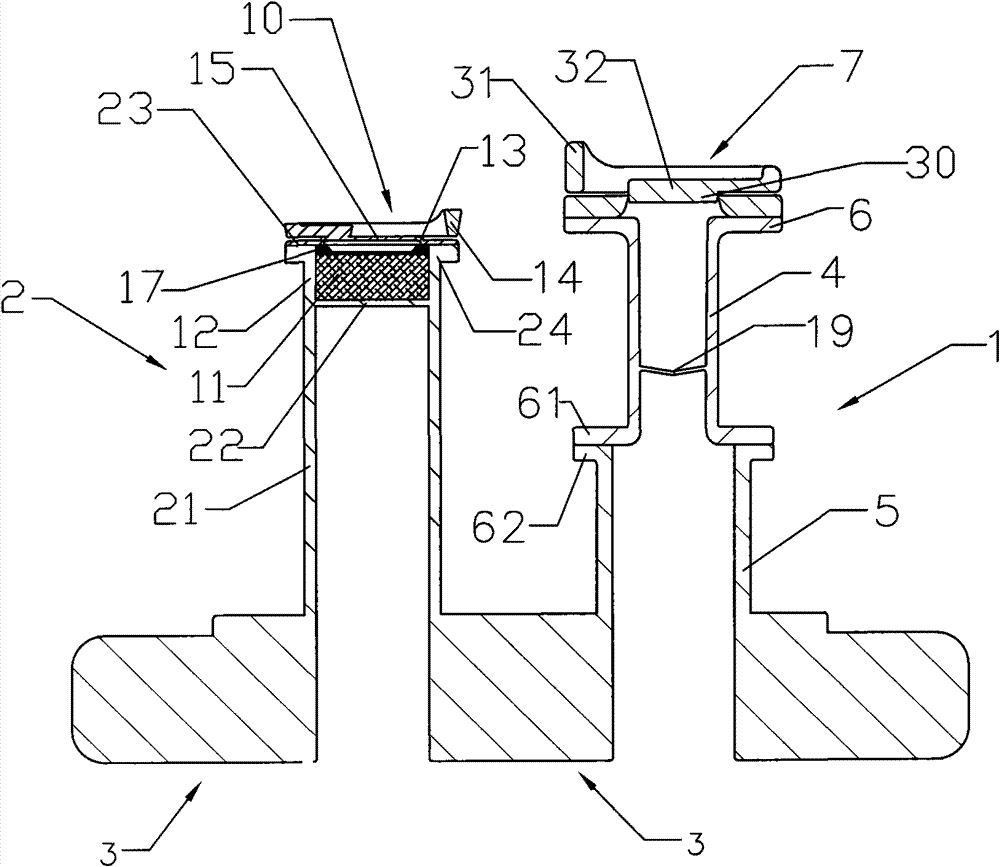

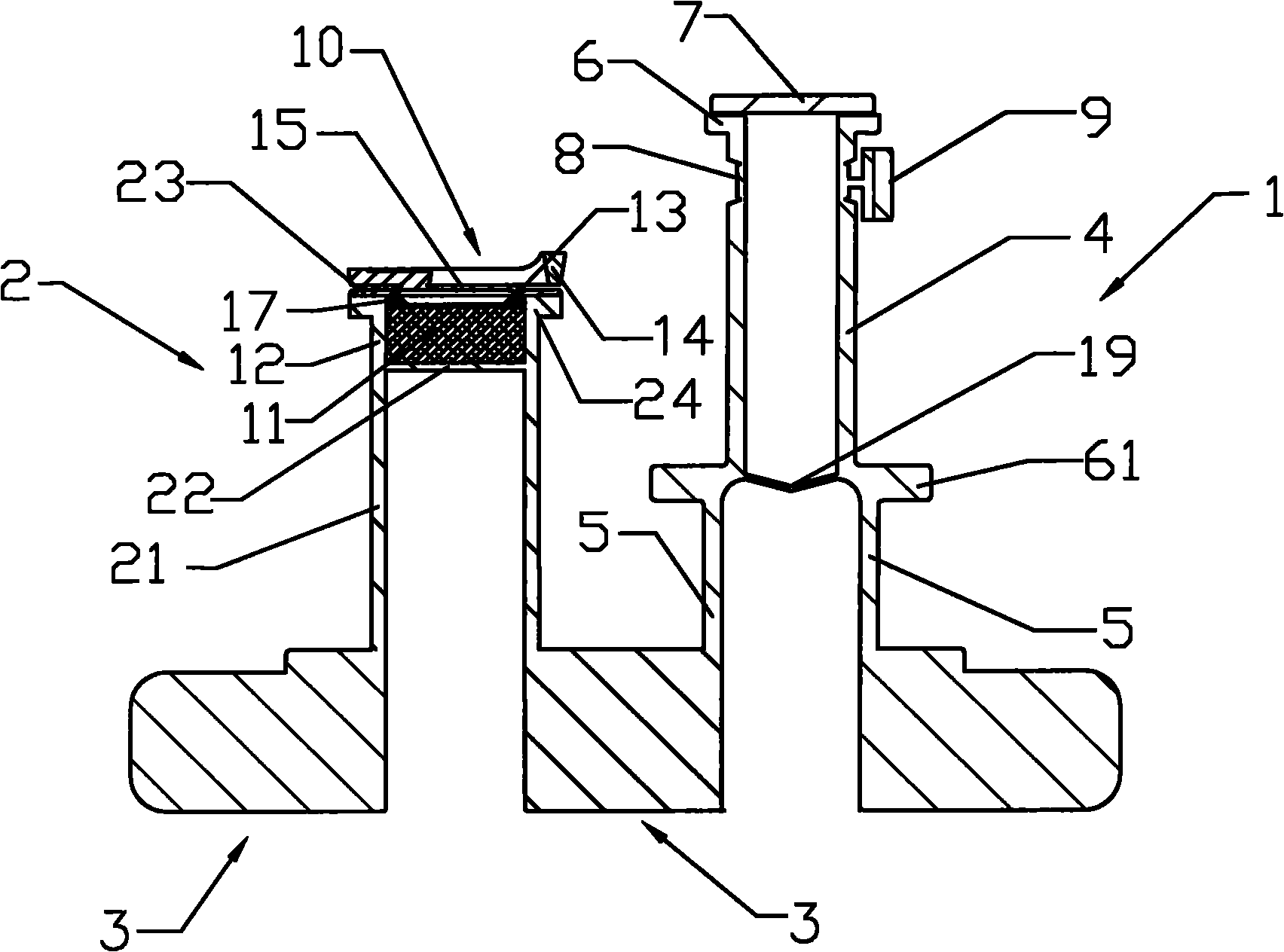

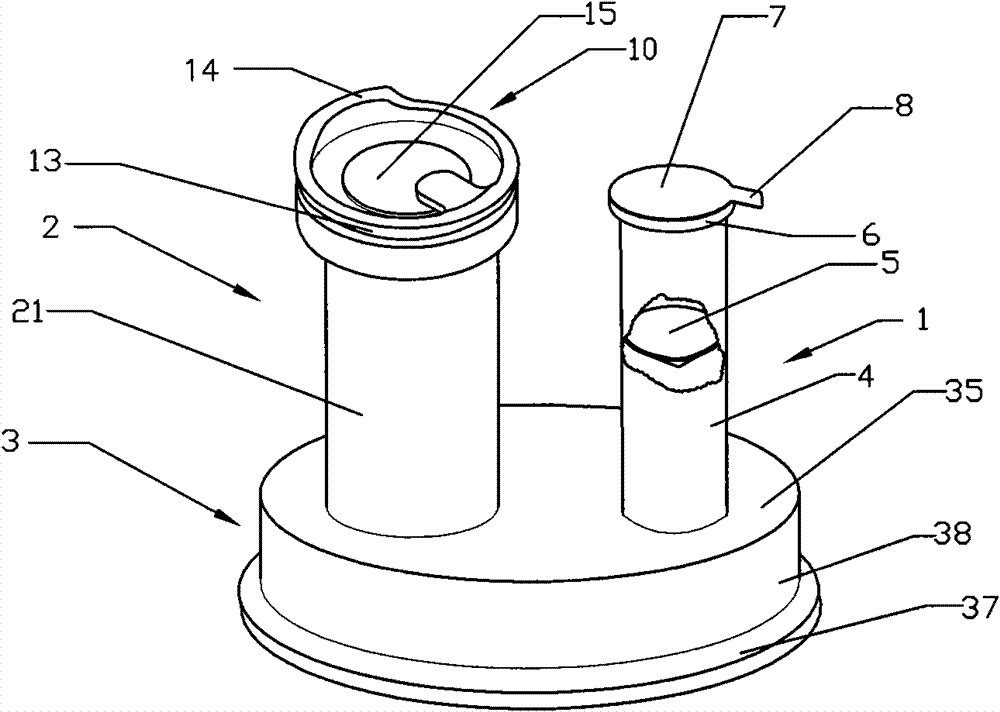

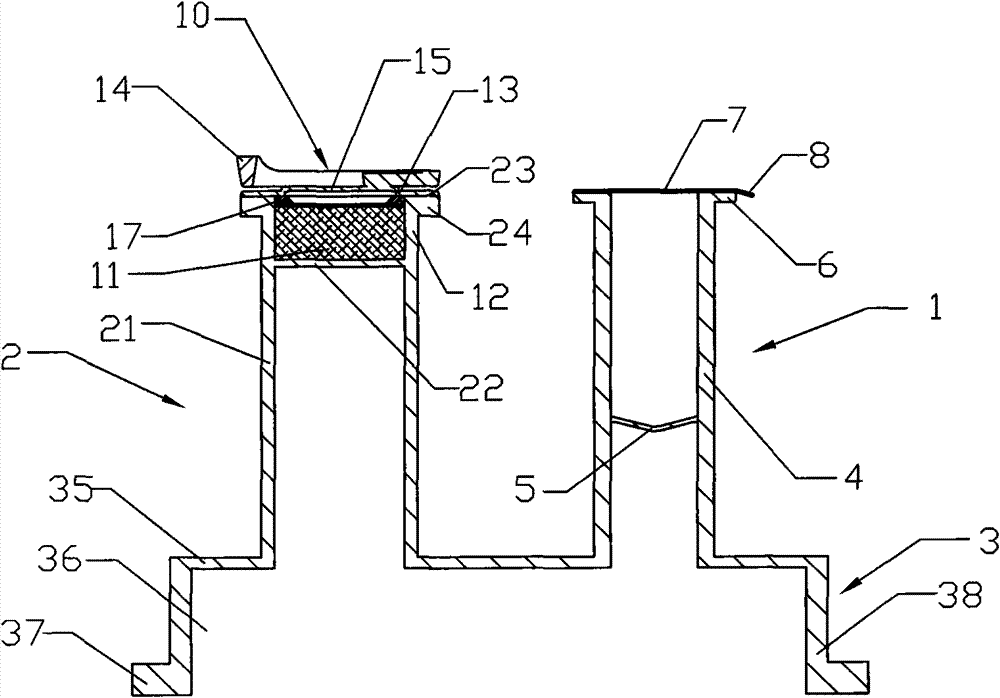

Transfusion container sealing cover with easily-torn sealing membrane transfusion pipe and drug feeding pipe

ActiveCN101804006AReduce manufacturing costNot easy to drop crumbsInfusion devicesPharmaceutical containersDouble tubeCatheter

The invention relates to a transfusion container sealing cover with an easily-torn sealing membrane transfusion pipe and a drug feeding pipe, belonging to a liquid inlet and outlet pipeline and a pipeline sealing device of a transfusion bottle (bag). The easily-torn sealing membrane transfusion pipe and the drug feeding pipe are fixed on the same surface of a cover bottom sheet of a cover body in parallel; the easily-torn membrane transfusion pipe comprises an easily-torn sealing membrane transfusion needle guide pipe and an easily-torn sealing membrane; the drug feeding pipe comprises a drug feeding pipe body, a gasket, a gasket fixing ring and an easy-open cover, the gasket is arranged on a gasket membrane, and the gasket fixing ring is arranged on the gasket; and the cover body comprises the circular cover bottom sheet, a hollow cylinder formed by connecting the side walls of the cover, and a cylinder welding ring formed by outwards extending the edge of the hollow cylinder. The invention has the advantages that double-pipe combiner can realize two functions of drug feeding and transfusion, and has difficult scrap dropping and easy puncture in the process of transfusing puncture; and the transfusion container sealing cover also has lower production cost.

Owner:SICHUAN KELUN PHARMA CO LTD

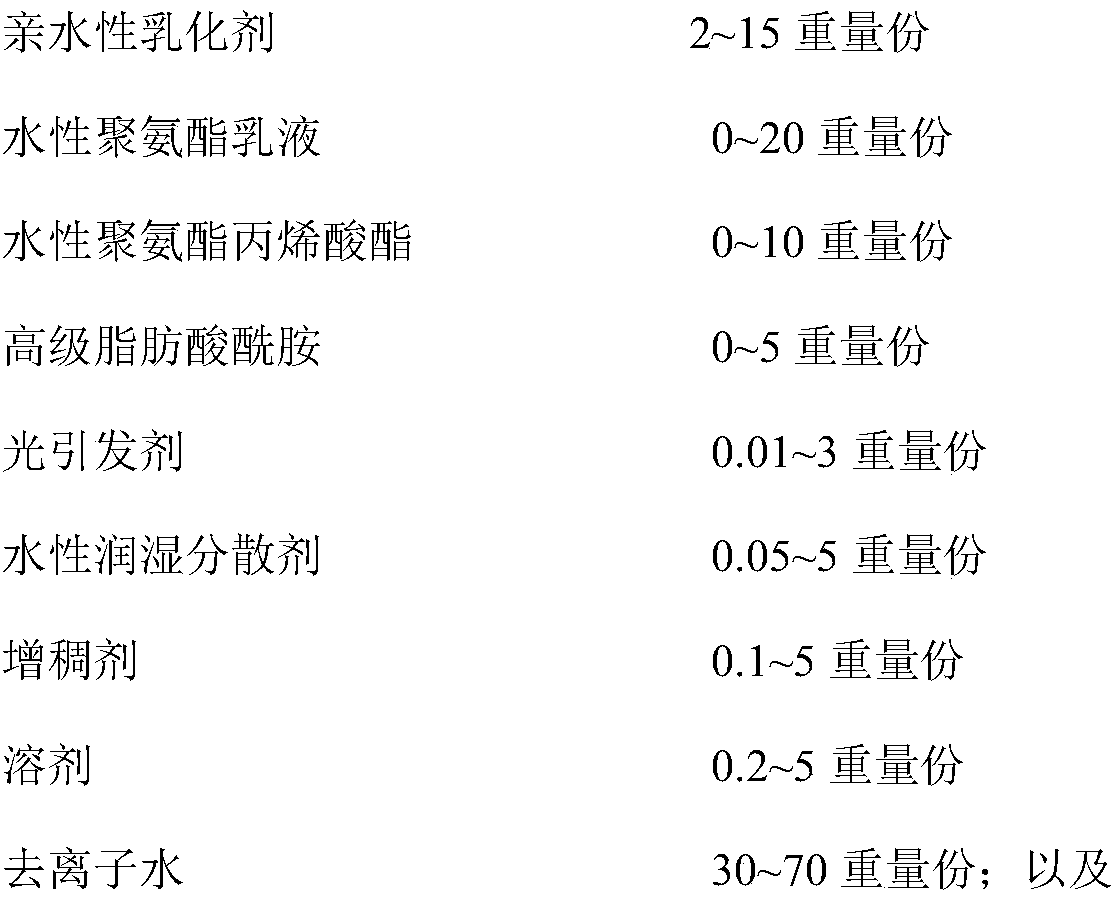

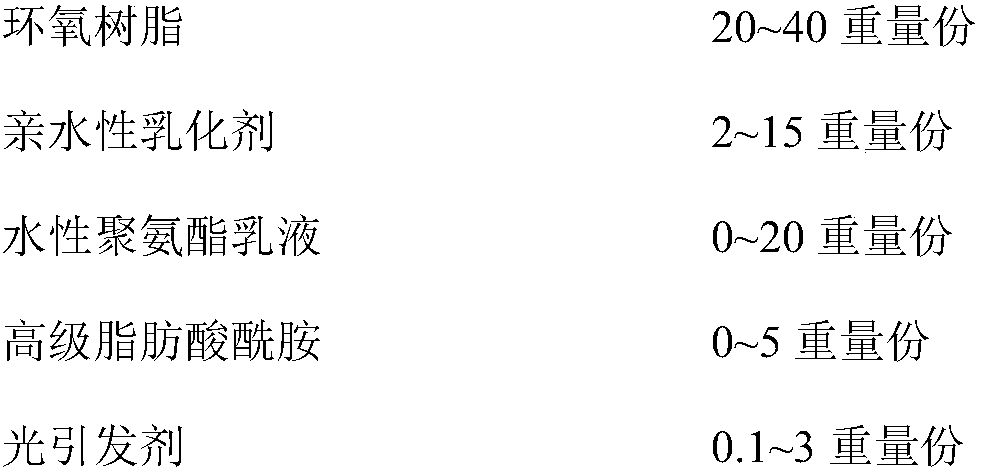

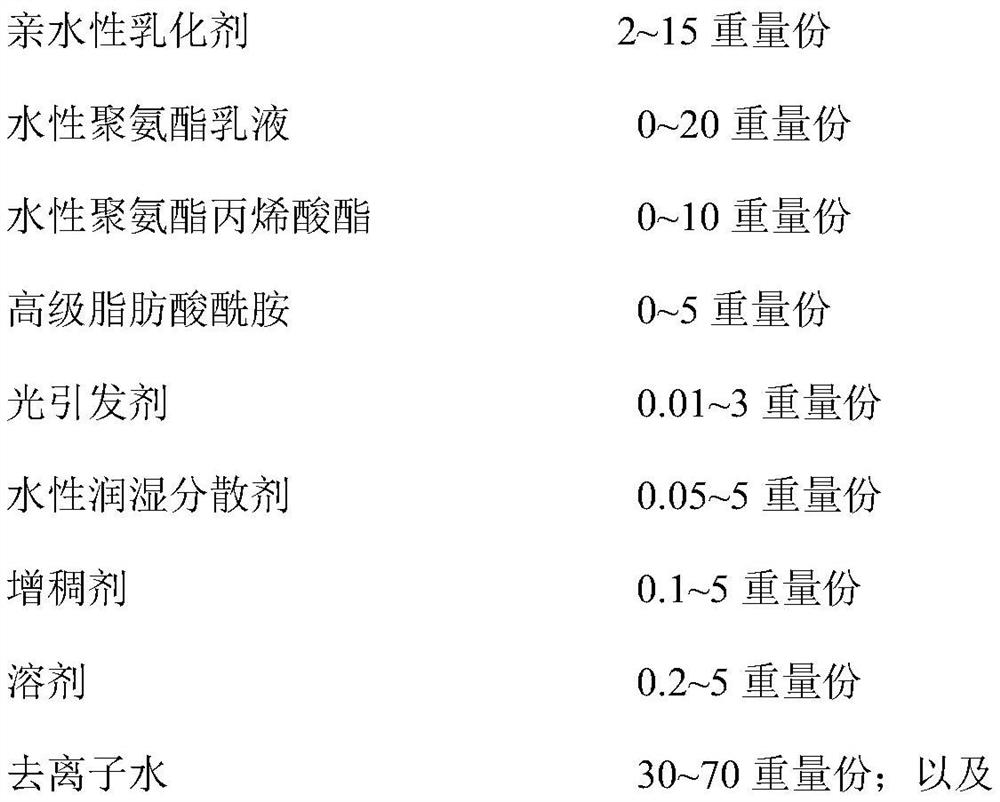

Aqueous carbon fiber sizing agent and preparation method of same

The invention discloses an aqueous carbon fiber sizing agent and a preparation method of same. The aqueous carbon fiber sizing agent is composed of, by weight, 20-40 parts of epoxy resin, 2-15 parts of a hydrophilic emulsifier, 0-20 parts of an aqueous polyurethane emulsion, 0-5 parts of higher fatty acid amide, 0.1-3 parts of a photo-initiator, 0.05-5 parts of an aqueous wetting dispersant, 0.1-5parts of a thickener, 0.2-5 parts of a solvent, and 30-70 parts of deionized water. The aqueous carbon fiber sizing agent integrates thermal curing and photo-curing, which can be firstly dried in a high temperature drying manner and then cured in a photo-curing manner, so that the performances of the sizing agent are further improved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Mooncake with Luchuan pig lean meat serving as stuffing

InactiveCN104273197AIncrease stickinessNot easy to drop crumbsDough treatmentBakery productsYolkLean meat

The invention relates to a mooncake with Luchuan pig lean meat serving as stuffing. The mooncake comprises mooncake skin and mooncake stuffing, flour, glutinous rice flour, yolk and chopped green onion serve as main ingredients of the mooncake skin, the mooncake skin is prepared from, by weight, 46-57 parts of the flour, 20-25 parts of the glutinous rice flour, 10-15 parts of the yolk, 5-10 parts of the chopped green onion and 4-8 parts of animal fat, and the mooncake stuffing is mainly prepared from, by weight, 23-34 parts of Luchuan pig lean meat, 30-35 parts of lotus paste, 10-15 parts of honey, 4-7 parts of chopped green onion and 3-5 parts of iodized edible refined salt. Compared with the prior art, the mooncake with the Luchuan pig lean meat serving as the stuffing has the advantages that the mooncake smells good when being unpacked, makes a great appetite for people and tastes excellent, and the mooncake skin is free of crumbs.

Owner:广西陆川县泓源食品有限公司

Infusion bag part with fusiform seat, side pull filling infusion tube and gasket ring dosing tube

ActiveCN101804008AReduce manufacturing costReduce the chance of leaksPharmaceutical containersMedical packagingDouble tubeCatheter

The invention relates to an infusion bag part with a fusiform seat, a side pull filling infusion tube and a gasket ring dosing tube, and belongs to a pipeline for liquid to pass in and out of an infusion bag and a pipeline sealing device. The side pull filling infusion tube and the dosing tube are basically parallel to each other and fixed on the same surface of the fusiform tube body seat; the side pull filling infusion tube consists of a connecting tube body, a side pull infusion needle conduit and a sealing strip; the dosing tube consists of a dosing tube body, a concave gasket groove, a gasket, a gasket fixing ring and an easy open end; and the gasket is provided with the gasket fixing ring which is in compression joint with the easy open end. The infusion bag part has the advantages that: the infusion bag part is a double tube integrated infusion bag part, can realize the functions of filling, dosing and infusing, reduce welding positions during infusion production, and reduce the probability of liquor leakage; and meanwhile, scraps are difficult to fall off in the process of infusion and puncture, the infusion bag part is convenient to puncture, and the production cost of the infusion bag part is relatively low.

Owner:SICHUAN KELUN PHARMA CO LTD

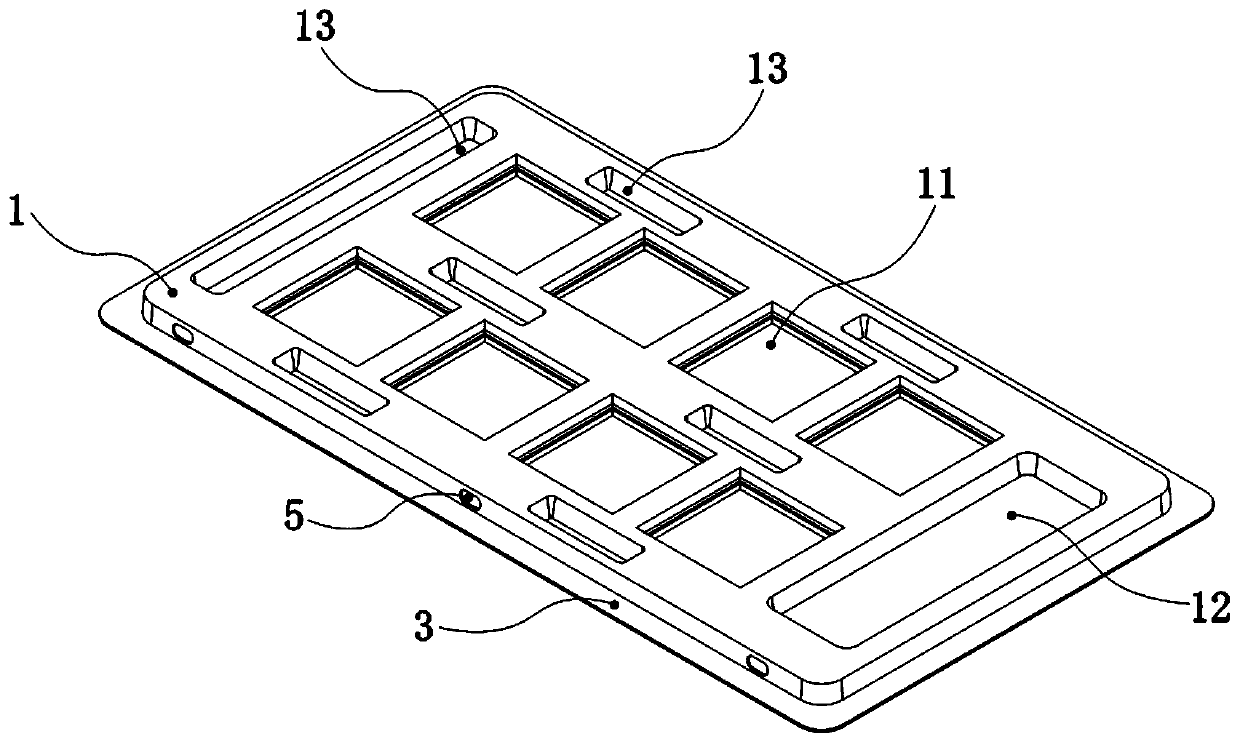

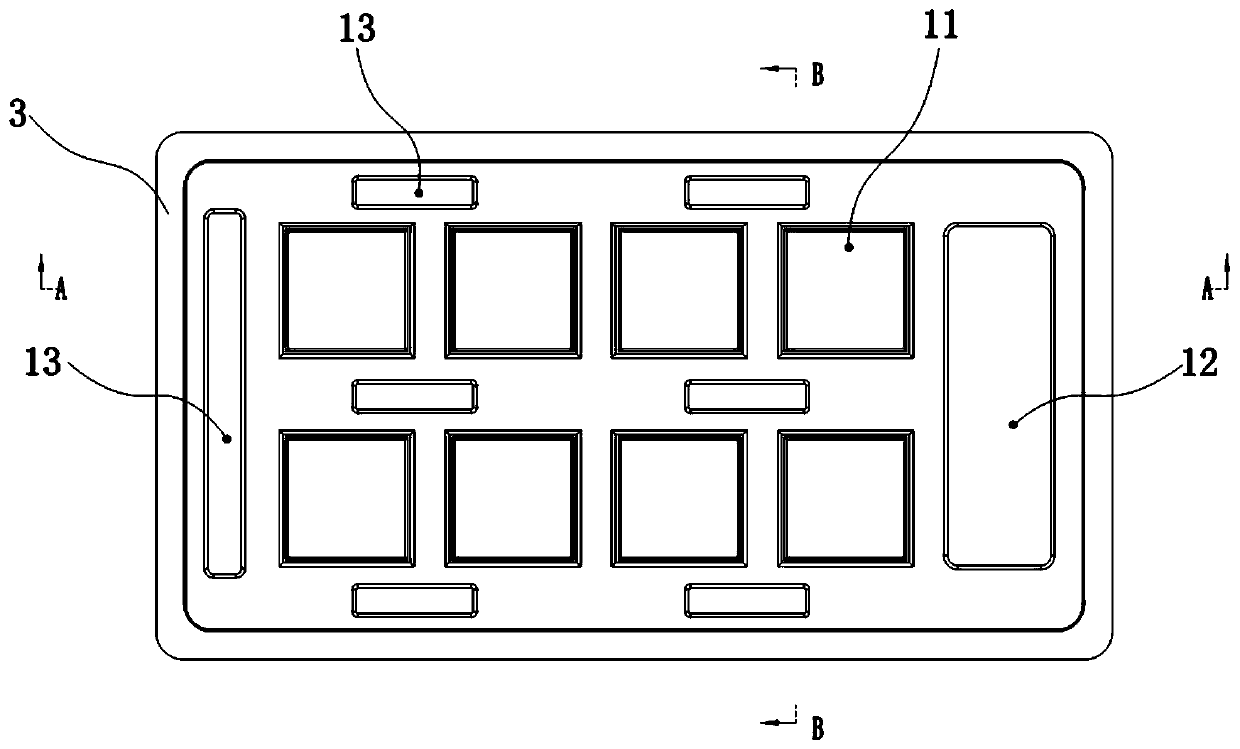

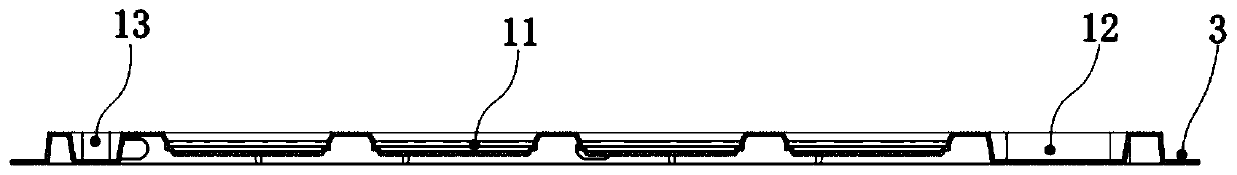

Chip packaging box and chip packaging method

InactiveCN110683221AImprove the protective effectNot easy to drop crumbsTray containersElectrical and Electronics engineeringScrap

The invention discloses a chip packaging box and a chip packaging method. The chip packaging box comprises a first cover body and a second cover body. The first cover body and the second cover body are of stereoscopic structures formed by die hot pressing or vacuum plastic uptake, and first grooves for containing chips and second grooves for containing auxiliary materials are formed in the first cover body. A first scrap is arranged on the outer side of the first cover body, a second scrap is arranged on the outer side of the second cover body, the second cover body is buckled on the first cover body, the first scrap and the second scrap are subjected to heat sealing, the chips can be packaged, the operation is easy, and the efficiency is high. Firstly, the first cover body and the secondcover body have good strength and buffer performance, protection of the chips is good, the chips are not easily broken, scraps do not easily fall, and the chips can be prevented from being contaminated. The packaging box has a good barrier property after heat sealing, the packaging box can be used for transportation and directly used for chip drying and packaging, and the material cost of a dryingand packaging bag is reduced.

Owner:SUZHOU TF AMD SEMICON CO LTD

Flame-retardant polyurethane gel prepolymer and preparation method thereof

The invention provides a flame-retardant polyurethane gel prepolymer which comprises, by weight, 20-30 parts of polyhydric alcohols 1000, 30-40 parts of polyhydric alcohols 2000, 15-25 parts of toluene diisocyanate, 6-10 parts of flame retardants, 2-4 parts of vulcanizing agents and 7-12 parts of plasticizers. The flame-retardant polyurethane gel prepolymer does not contain any toxic and harmful substances and other filled materials and is a novel water-tolerant and oil-retardant environment-friendly flame-retardant material, and the hardness of the prepolymer ranges from 0A to 98A. The prepolymer has the advantages that the prepolymer is good in surface viscosity and elasticity, high in adhesion force, stable in surface hardness, environmentally friendly, durable, retardant in flame, oil, abrasion and solvent corrosion, anti-static and easy to clean and does not easily ages and falls scraps, the performance of the prepolymer cannot reduce when the prepolymer is used for a long time and the like. The prepolymer is used for producing mobile phone charging test devices, anti-aging detection devices, automotive parts and components, fireproofing doors and windows, charging piles, battery tanks and medical facilities and the like. The invention further provides a preparation method of the flame-retardant polyurethane gel prepolymer. The preparation method is simple, practicable and good in stability.

Owner:SHENZHEN LIXIN LUNAN RUBBER & PLASTIC HARDWARE

Production process of hot-rolled non-woven base fabric for packaging

InactiveCN110344176AGuarantee product qualityImprove structural strengthSynthetic resin layered productsNon-woven fabricsFiberPolyester

The invention discloses a production process of a hot-rolled non-woven base fabric for packaging, and aims to overcome the defects of difficulty in tearing, easiness in moisture absorption and mildewof paper packaging. According to the invention, two short fibers are proportioned and mixed, polyester short fibers are the main body of the product, so that the temperature resistance effect is achieved, a certain thickness is achieved in the processing course, and a material supporting effect is achieved. The low-melting-point polyester staple fibers play a bonding role in the product, glue coating can be omitted when the formed product is made into a packaging bag, and the product has a self-bonding effect. After fiber carding, the individual fibers are laid along the carding direction, sothat the formed cloth is easy to tear along the carding direction. A mesh surface with certain thickness and air permeability is formed between the fibers, so that the packaging material has effects of supporting, air permeability and water impermeability, and is not easy to absorb moisture and mildew.

Owner:杭州金百合非织造布有限公司

Sesame cake and production method thereof

The invention discloses a sesame cake and a production method thereof in the technical field of processing of byproducts. The sesame cake is produced from the following raw materials in parts by weight: 10-15 parts of sticky rice, 3-5 parts of peanut kernels, 2-4 parts of sesame, 2-4 parts of common perilla seeds, 2-3 parts of walnut kernels, 2-3 parts of maltose, 0.5-1 part of honey, 0.5-1 part of rock candy, 0.5-1 part of brown sugar, 0.5-0.6 part of white sugar and 0.02-0.03 part of salt. The sesame cake disclosed by the invention is fragrant, sweet, crisp, full of nutrients and unique in flavour, does not stain hands, is easy to carry and low in content of unsaturated fatty acid, can not cause burden and influence on body and can not cause disease after being eaten due to the burden and body; meanwhile, the selected honey, peanut, sticky rice and common perilla seeds have the effects of maintaining beauty and keeping young, replenishing blood and reducing dryness as well as clearing internal heat and lubricating intestines, so that the sesame cake disclosed by the invention has extremely high health value, is convenient to popularize and apply and is a good item as a present to relatives and friends.

Owner:习家瑞

Anti-flaming anti-static polyurethane prepolymer and preparation method thereof

InactiveCN106753157AGood surface stickinessIncrease elasticityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesHazardous substanceSolvent

The invention provides anti-flaming anti-static polyurethane prepolymer which is prepared from the following ingredients in parts by weight: 25 to 35 parts of polyhydric alcohols 1000, 20 to 30 parts of polyhydric alcohols 2000, 15 to 25 parts of toluene diisocynate, 8 to 12 parts of flame retardant, 3 to 5 parts of vulcanizing agent and 10 to 12 parts of antistatic agent. The anti-flaming anti-static polyurethane prepolymer disclosed by the invention does not contain any toxic and harmful substance and other filler materials and is a waterproof and oil-proof environment-friendly anti-static novel material; a hardness range is 0A to 98A; the anti-flaming anti-static polyurethane prepolymer has the excellent characteristics of good surface viscosity, strong adhesive power, good elasticity, stable surface hardness, environmental friendliness, durability, flame resistance, static resistance, difficulty in ageing, no scrap, easiness to clean, oil resistance, wear resistance, solvent corrosion resistance, non-decreasing use performance for a long time and the like. The invention further provides a preparation method of the anti-flaming anti-static polyurethane prepolymer, and the preparation method is simple and easy to implement and has high stability and high production efficiency.

Owner:SHENZHEN LIXIN LUNAN RUBBER & PLASTIC HARDWARE

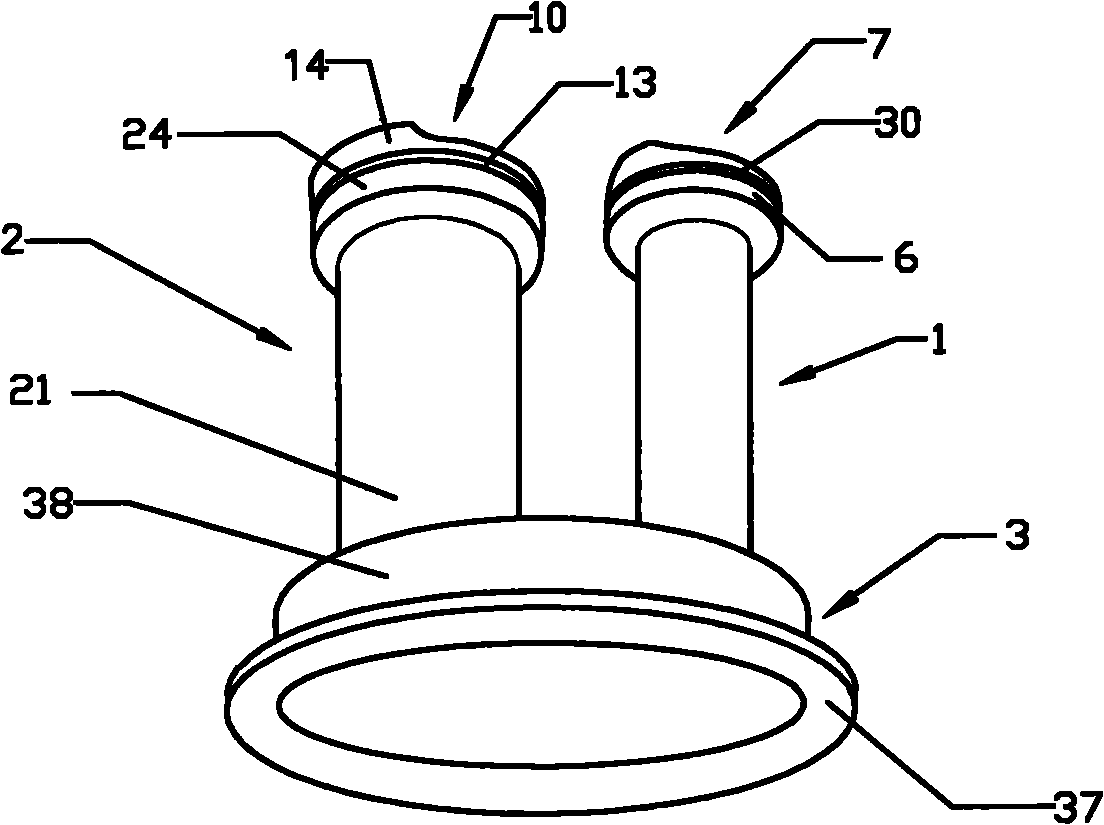

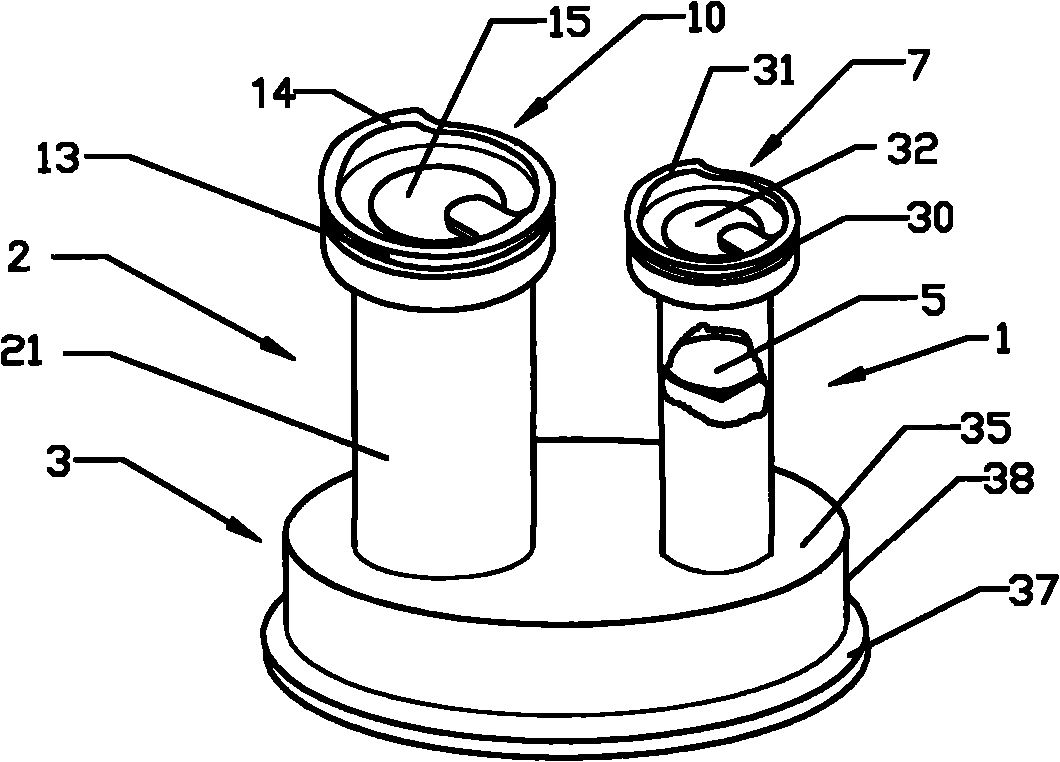

Infusion bag part with fusiform seat, top pull filling infusion tube and gasket ring dosing tube

ActiveCN101804010BReduce manufacturing costReduce the chance of leaksInfusion devicesPharmaceutical containersDouble tubeCatheter

The invention relates to an infusion bag part with a fusiform seat, a top pull filling infusion tube and a gasket ring dosing tube, and belongs to a pipeline for liquid to pass in and out of an infusion bag and a pipeline sealing device. The infusion bag part comprises the top pull filling infusion tube, the dosing tube and the fusiform tube body seat, and is characterized in that: the top pull filling infusion tube and the dosing tube are fixed on the same surface of the fusiform tube body seat and basically parallel to each other; the top pull filling infusion tube is hollow and provided with a sealing diaphragm, and the top end of the top pull filling infusion tube is provided with a top pull sealing cover for sealing the top pull filling infusion tube; and the top of the dosing tube is sealed by a gasket and an easy open end. The infusion bag part has the advantages that: the infusion bag part is a double tube integrated infusion bag part, can realize the functions of filling, dosing and infusing, reduce welding positions during infusion production, and reduce the probability of liquor leakage; and meanwhile, scraps are difficult to fall off in the process of infusion and puncture, the infusion bag part is convenient to puncture, and the production cost of the infusion bag part is relatively low.

Owner:SICHUAN KELUN PHARMA CO LTD

Aqueous carbon fiber sizing agent and preparation method thereof

ActiveCN109385899BImprove performanceIncrease productivityCarbon fibresGrip property fibresEpoxyPolymer science

The invention discloses a water-based carbon fiber sizing agent and a preparation method thereof. The water-based carbon fiber sizing agent is made of the following components in parts by weight: 16-32 parts by weight of epoxy resin, 4-8 parts by weight of epoxy acrylate; 2-15 parts by weight of hydrophilic emulsifier; water-based polyurethane emulsion 0-20 parts by weight; 0-10 parts by weight of water-based polyurethane acrylate; 0-5 parts by weight of higher fatty acid amide; 0.01-3 parts by weight of photoinitiator; 0.05-5 parts by weight of water-based wetting and dispersing agent; 5 parts by weight; 0.2-5 parts by weight of solvent; 30-70 parts by weight of deionized water. The water-based carbon fiber sizing agent of the present invention is a water-based carbon fiber sizing agent combined by heat curing and light curing. The carbon fiber after the sizing can be dried by high-temperature heat drying, and then cured by light curing, so that the carbon fiber The performance of the sizing agent is further improved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

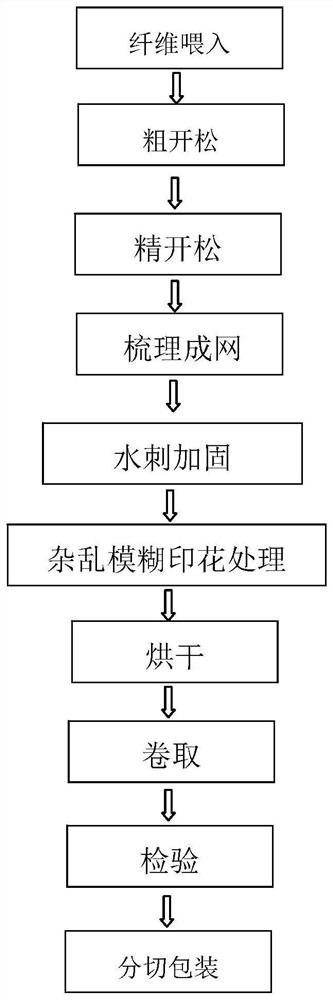

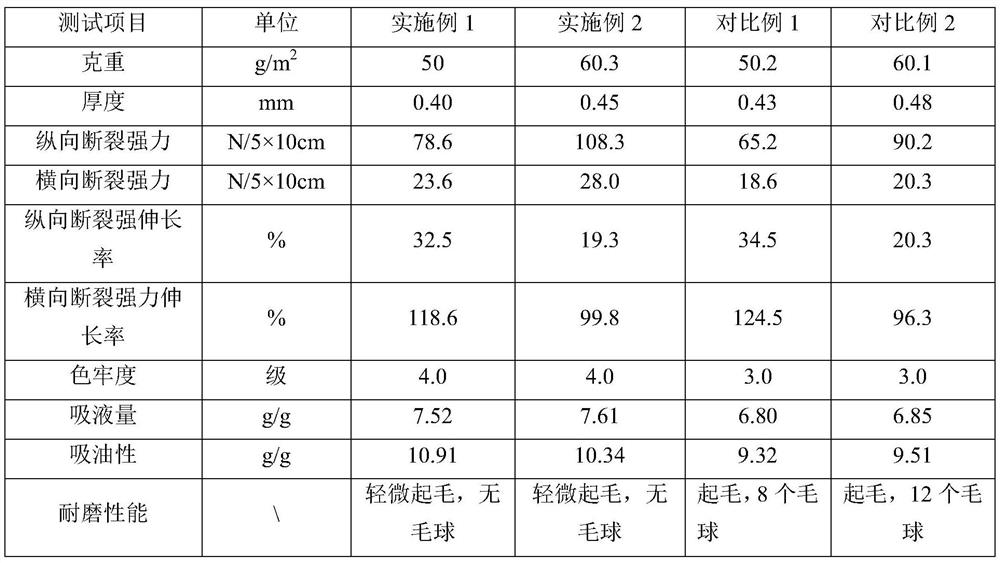

Spunlace disordered fuzzy printed cloth and preparation method thereof

ActiveCN112030357ANot easy to drop crumbsImprove water absorptionDyeing processNon-woven fabricsTextile printerColour fastness

The invention relates to a preparation method of a spunlace disordered fuzzy printed cloth. The preparation method comprises the following steps of fiber feeding, coarse opening, fine opening, cardingweb-forming, spunlace reinforcement, disordered fuzzy printing treatment, drying, reeling and inspection. The invention further provides the spunlace disordered fuzzy printed cloth prepared through the method. The spunlace disordered fuzzy printed cloth is obtained through an online disordered fuzzy printing technology for a spunlace cloth, a technological method selected in the technology is proper, and the produced disordered fuzzy printed cloth with non-continuous patterns such as star-shaped patterns, diamond patterns and rhombic patterns is free of scrap falling and dizziness and has theadvantages of being better in liquid absorption diffusion, resistant to washing and abrasion and the like; and the spunlace disordered fuzzy printed cloth is gradually changed in color, diversified in color and high in color fastness, and reaches the international advanced level.

Owner:XINLONG HLDG GROUP +1

Infusion bag part with fusiform seat, side pull infusion tube and gasket ring dosing tube

ActiveCN101804007AReduce manufacturing costReduce the chance of leaksInfusion devicesPharmaceutical containersDouble tubeCatheter

The invention relates to an infusion bag part with a fusiform seat, a side pull infusion tube and a gasket ring dosing tube, and belongs to a pipeline for liquid to pass in and out of an infusion bag and a pipeline sealing device. The side pull infusion tube and the dosing tube are basically parallel to each other and fixed on the same surface of the fusiform tube body seat; the side pull infusion tube consists of a connecting tube body, a side pull infusion needle conduit and a sealing strip; the dosing tube consists of a dosing tube body, a concave gasket groove, a gasket, a gasket fixing ring and an easy open end; and the gasket is provided with the gasket fixing ring which is in compression joint with the easy open end. The infusion bag part has the advantages that: the infusion bag part is a double tube integrated infusion bag part, can realize the functions of dosing and infusing, reduce welding positions during infusion production, and reduce the probability of liquor leakage; and meanwhile, scraps are difficult to fall off in the process of infusion and puncture, the infusion bag part is convenient to puncture, and the production cost of the infusion bag part is relativelylow.

Owner:SICHUAN KELUN PHARMA CO LTD

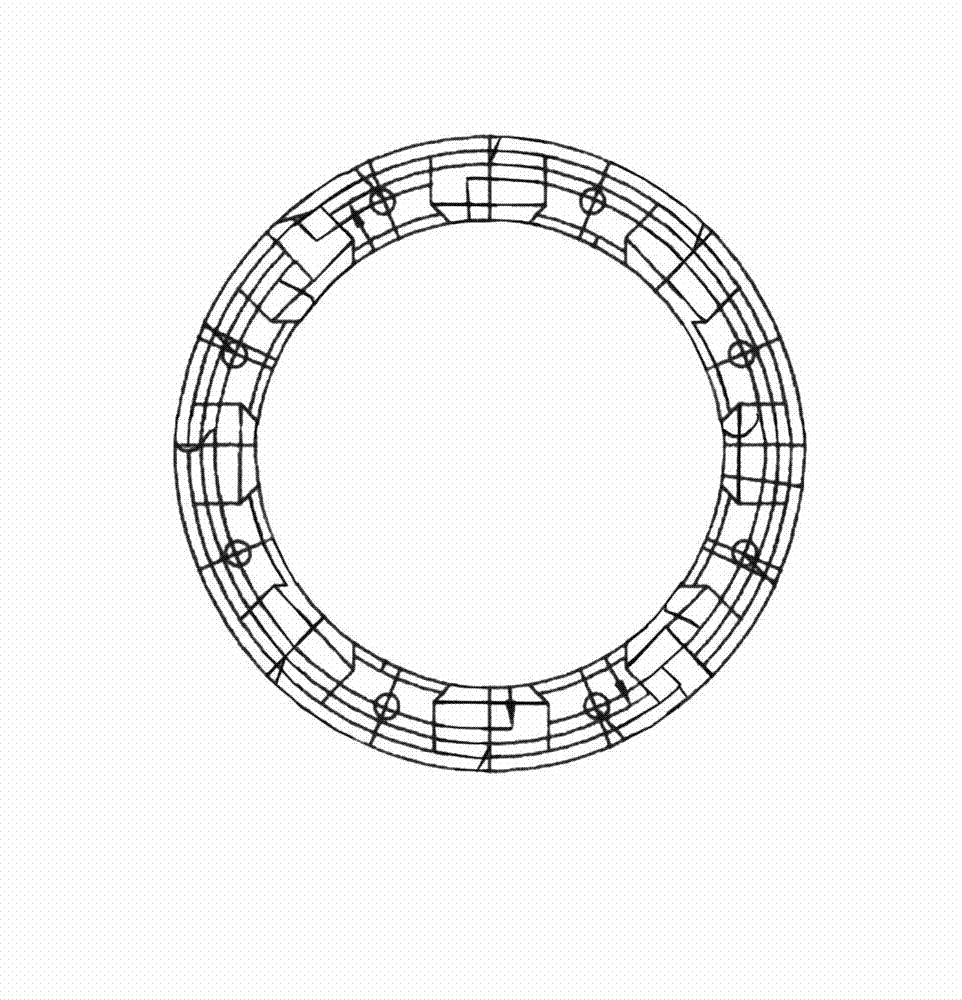

Application of high-toughness low-expansion zinc-based wear-resisting alloy for production of bearing cage

InactiveCN102758102AChange the production processImprove working precisionBearing componentsAlloyCobalt

The invention discloses application of a high-toughness low-expansion zinc-based wear-resisting alloy for production of a bearing cage. The alloy comprises, by weight, 55-65% of zinc, 20-30% of aluminum, 10-15% of intermediate alloy aluminum and 1-2% of aluminum cobalt. A method for producing the bearing cage comprises that materials are smelted, cast and molded by a mold and subjected to finish machining, and then the high-toughness low-expansion zinc-based wear-resisting alloy bearing cage is produced. According to the application of the high-toughness low-expansion zinc-based wear-resisting alloy for the production of the bearing cage, production materials and production processes of traditional bearing cages are changed, the specific gravity of the bearing cage is reduced to 4.8, the wearing resistance and the strength of the bearing cage are better than those of lead bronze, the starting resistance is low, the bearing cage is not easy to wear, scraps are not easy to fall, the bearing cage are good in material oil immersion performance, and a layer of protective oil film can be formed on every working surface. According to the application, the alloy is low in starting resistance, free from scrap falling during operation, reliable in operation, good in stability and high in working precision, so that the alloy is the preferred application material for current processing of the bearing cage.

Owner:HEILONGJIANG HUAITE NEW MATERIALS

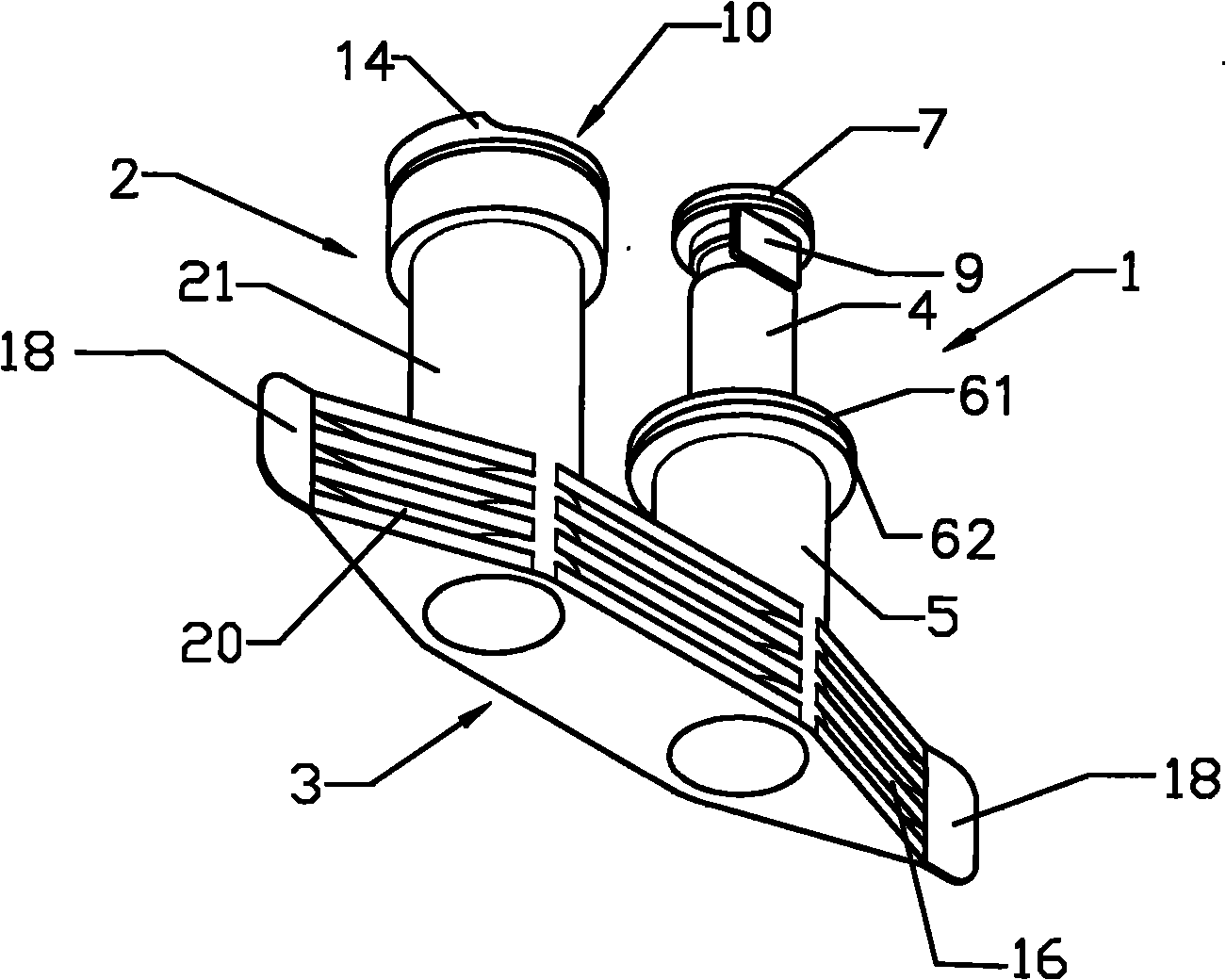

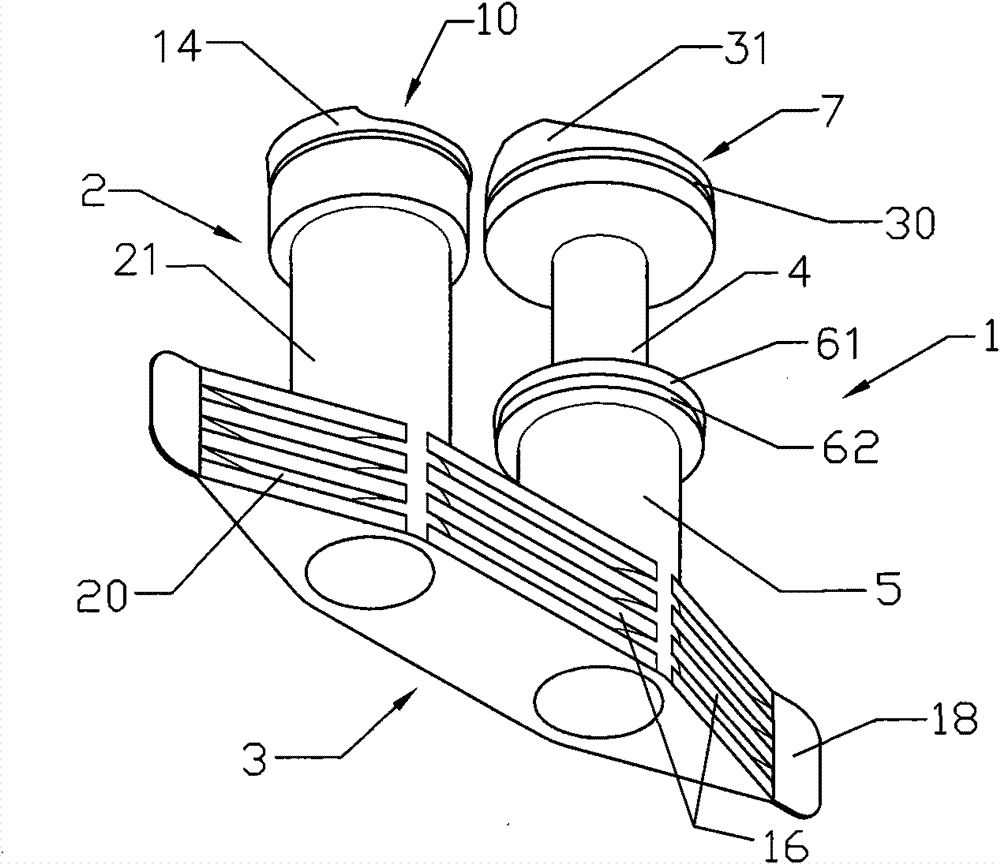

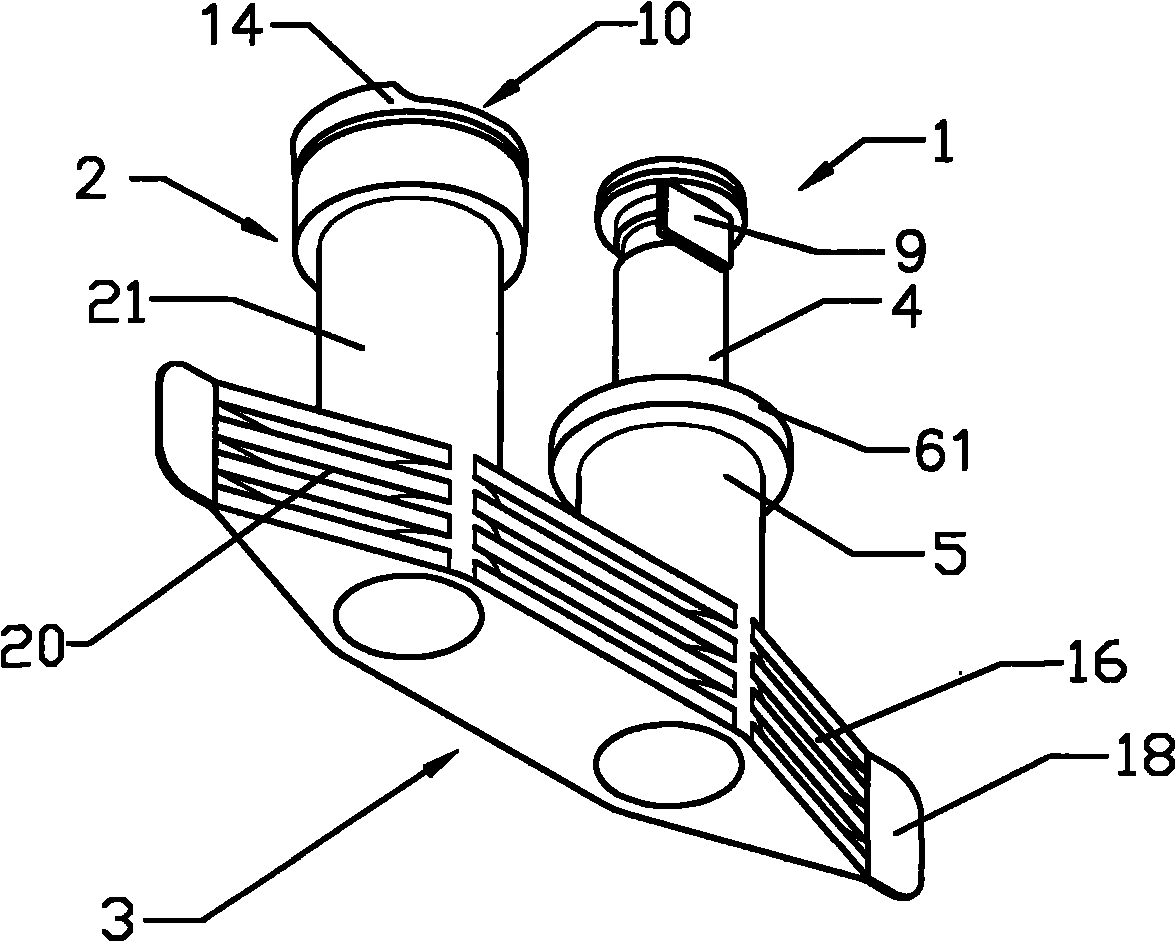

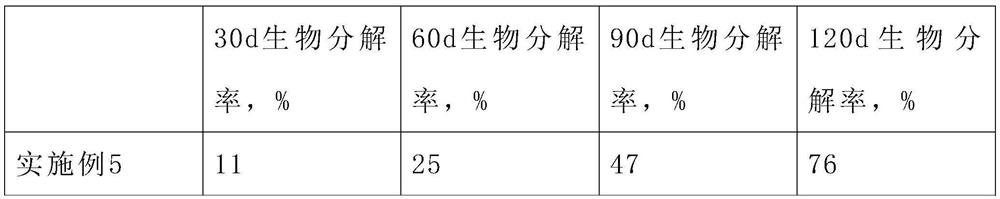

Transfusion container sealing cover with top-pull type transfusion pipe and drug feeding pipe

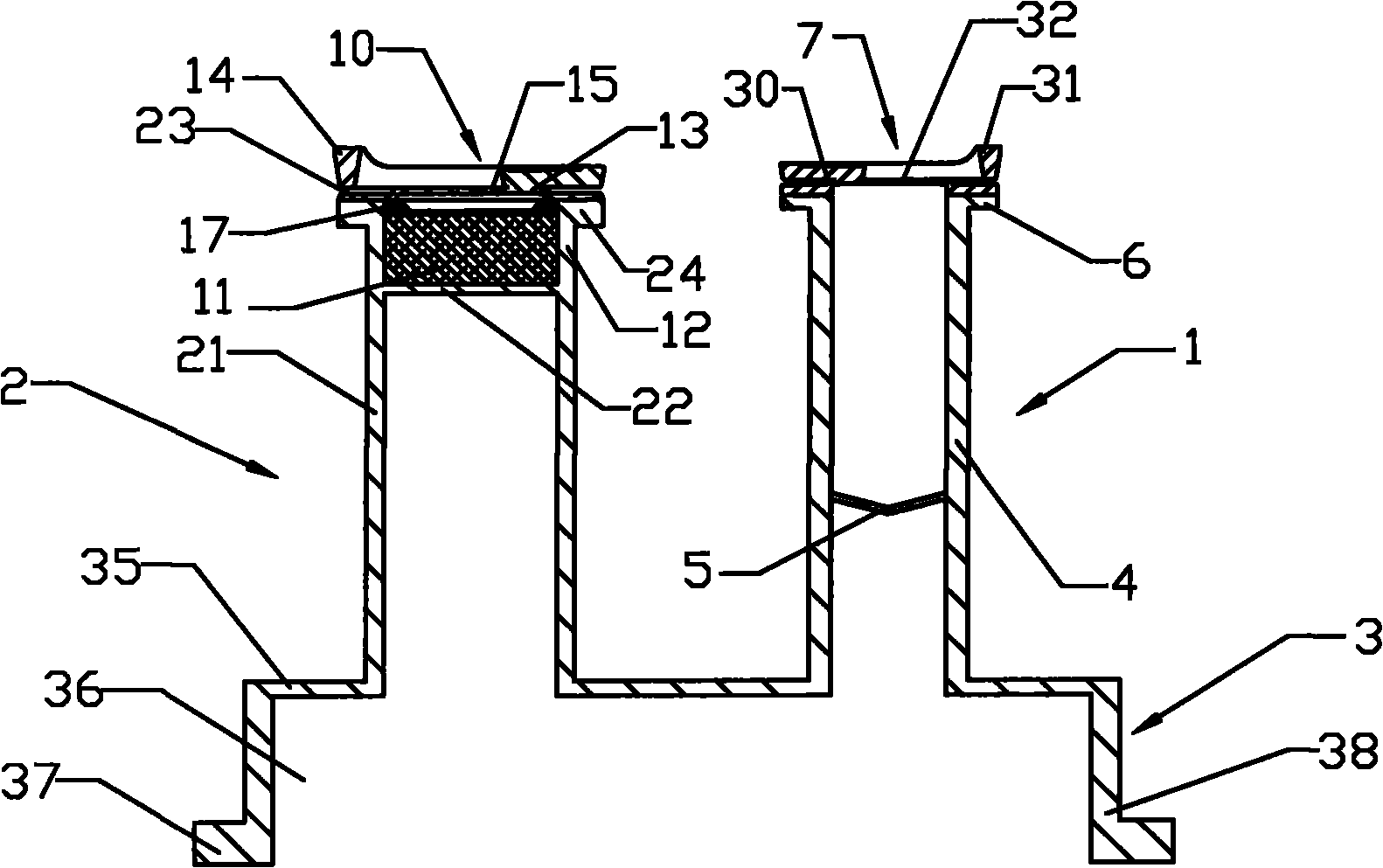

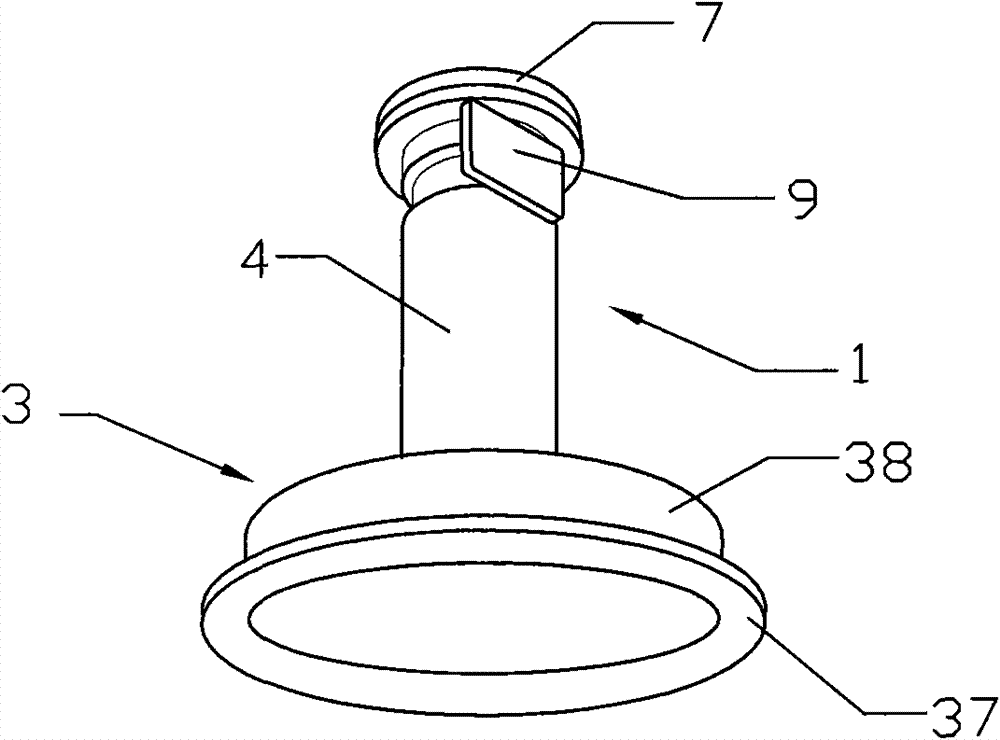

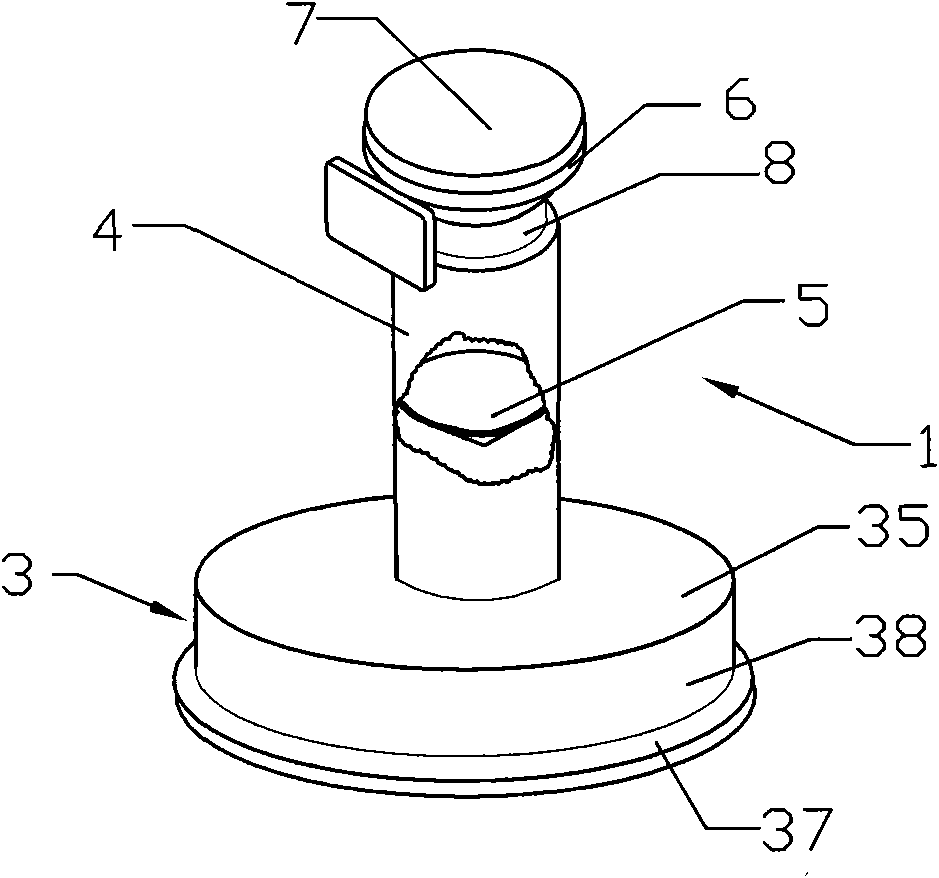

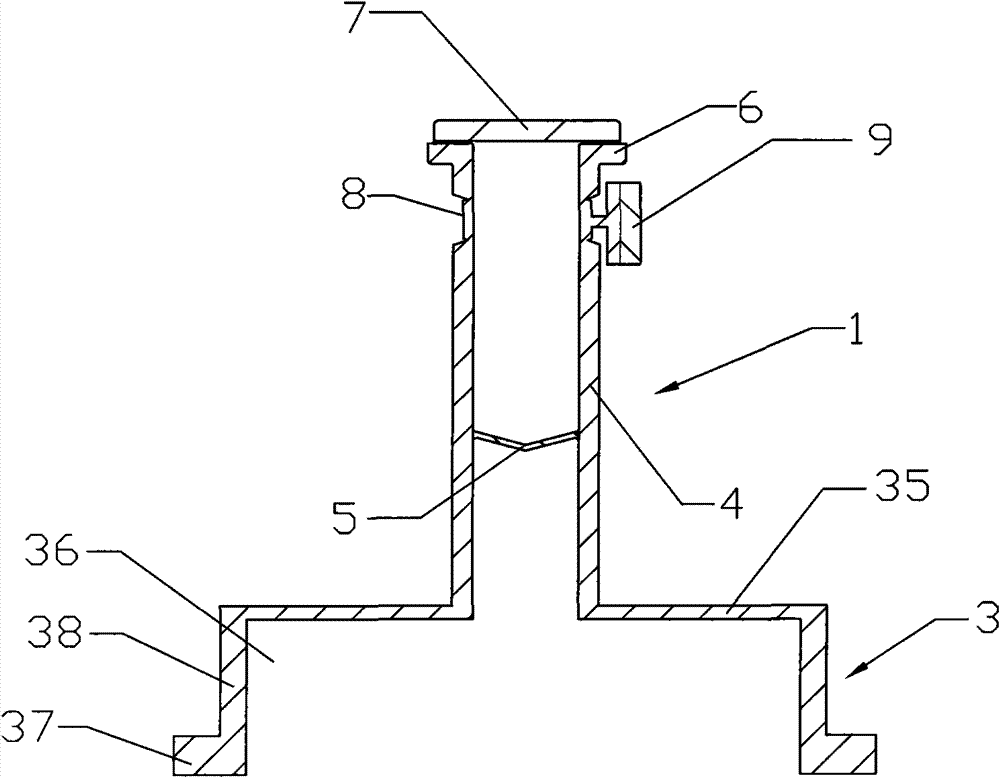

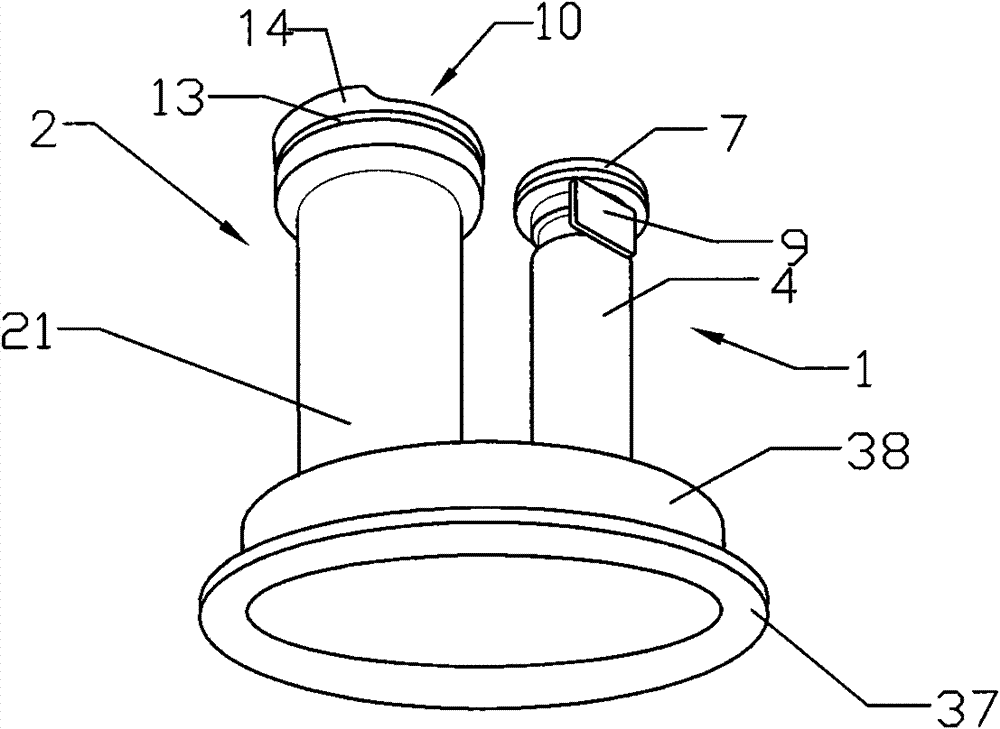

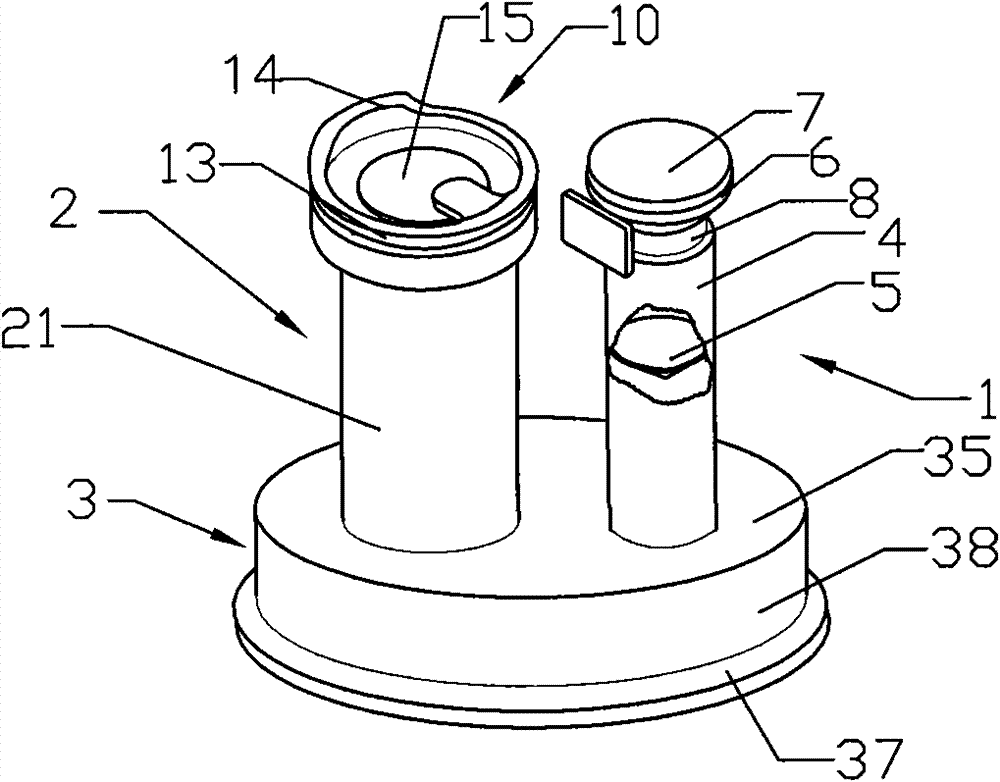

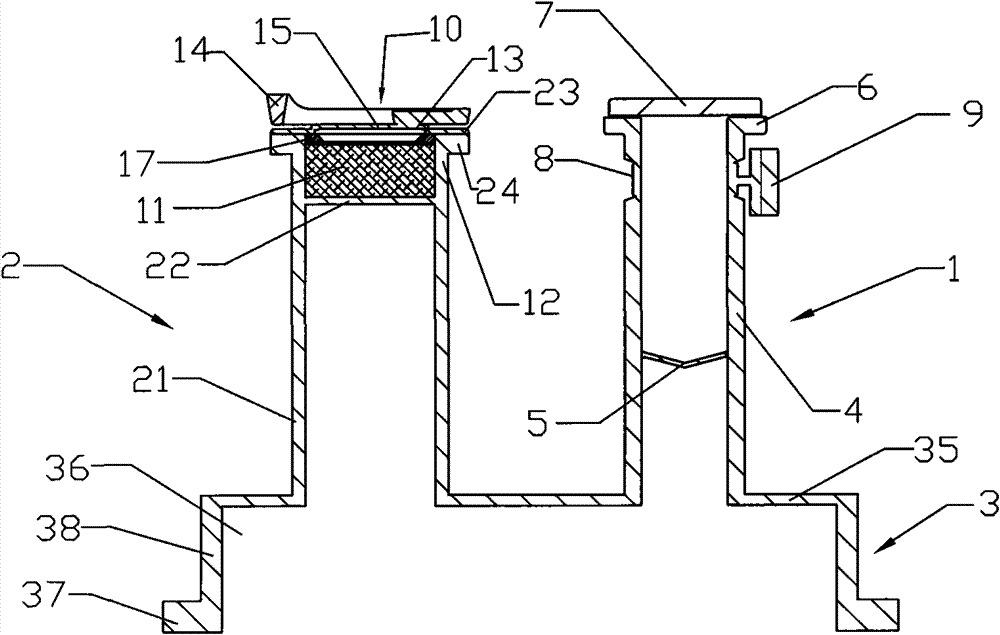

ActiveCN101804005AReduce manufacturing costNot easy to drop crumbsPharmaceutical containersMedical packagingNeedle guideHollow cylinder

The invention relates to a transfusion container sealing cover with a top-pull type transfusion pipe and a drug feeding pipe, belonging to a liquid inlet and outlet pipeline of a transfusion bottle (bag) and a pipeline sealing device. The top-pull type transfusion pipe and the drug feeding pipe are fixed on the same surface of a cover body basically in parallel; the top-pull type transfusion pipe comprises a top-pull type transfusion needle guide pipe and a top-pull type sealing cover; the drug feeding pipe comprises a drug feeding pipe body, a gasket, a gasket fixing ring and an easily-pull cover, wherein the gasket is arranged on a gasket membrane, and the gasket fixing ring is arranged on the gasket; the cover body comprises a cover bottom sheet, a hollow cylinder and a cylinder welding ring, wherein the hollow cylinder is formed by connecting the side walls of the cover, and the cylinder welding ring is formed by outwards extending the edge of the hollow cylinder. The invention has the advantages that a double-pipe connector can realize two functions of drug feeding and transfusion, and the transfusion container sealing cover has difficult scrap dropping and easy puncture in the process of transfusing puncture; and the transfusion container sealing cover also has lower production cost.

Owner:SICHUAN KELUN PHARMA CO LTD

Flame-retardant antistatic polyurethane elastomer and preparation method thereof

InactiveCN111961431AStable hardnessGood surface stickinessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane elastomerPolymer science

The invention provides a flame-retardant antistatic polyurethane elastomer. A prepolymer of the flame-retardant antistatic polyurethane elastomer comprises the following components in parts by weight:25-35 parts of polyol 1000, 20 to 30 parts of a polyol 2000; 15 to 25 parts of toluene diisocynate; 8 to 12 parts of a flame retardant; 3-5 parts of a vulcanizing agent; and 10 to 12 parts of an antistatic agent. The flame-retardant anti-static polyurethane elastomer does not contain any toxic and harmful substances and other filling materials, is a water-resistant and oil-resistant environment-friendly anti-static flame-retardant new material, has the hardness range of 0A-98A, and has the advantages of good surface viscosity, strong adhesive force, good elasticity, stable surface hardness, environmental protection, durability, flame retardance, static resistance, difficulty in aging, no chip falling, easiness in cleaning, oil resistance, wear resistance and solvent corrosion resistance.The long-time use performance is not reduced, and the like. The invention further provides a preparation method of the flame-retardant anti-static polyurethane elastomer. The preparation method is simple and easy to implement, high in stability and high in production efficiency.

Owner:SHENZHEN LIXIN LUNAN RUBBER & PLASTIC HARDWARE

Preparation method of sponge formed by embedding of porous network material and polyvinyl alcohol porous foamed sponge

InactiveCN101649066BStrong cleaning and decontamination abilityDeformableCarpet cleanersKitchenware cleanersWire gauzePolymer science

The invention provides a preparation method of sponge formed by embedding of porous network material and polyvinyl alcohol porous foamed sponge. The making steps include that: firstly polyvinyl alcohol aqueous solution is prepared and warmed, pore-forming agent, antifoaming agent, cross linker and crosslink catalyst are respectively added in to the polyvinyl alcohol aqueous solution, rapid stirring is carried out to obtain polyvinyl alcohol mixed solution, then steel wire gauze material is placed in a container; then the polyvinyl alcohol mixed solution is poured into the container, pressurizing equipment is adopted to pressurize the steel wire gauze, bubble exhaust and air exhaust are carried out, and pressurizing and bubble exhaust are carried out again, the container is sealed and secondary air exhaust is carried out, the container is placed in a thermostat for warming and curing, the products are cleaned, sliced and packed into sponge for cleaning, not only cleaning and decontamination are easy and cleaning agent remaining efficiency is high but also handfeel is good, no scrap drops, no germ grows, and the sponge is environmentally friendly and sanitary.

Owner:黄建辉

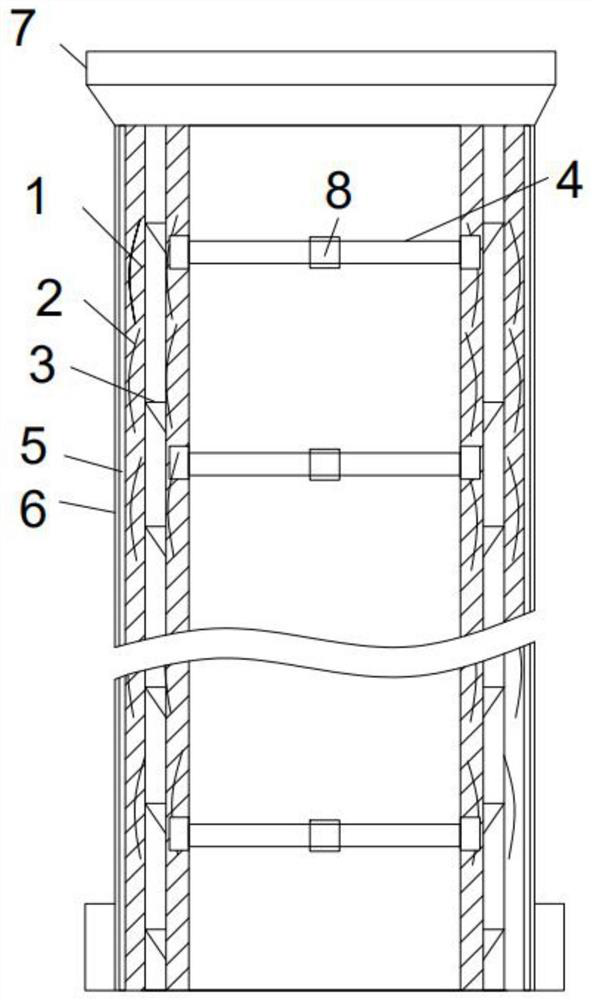

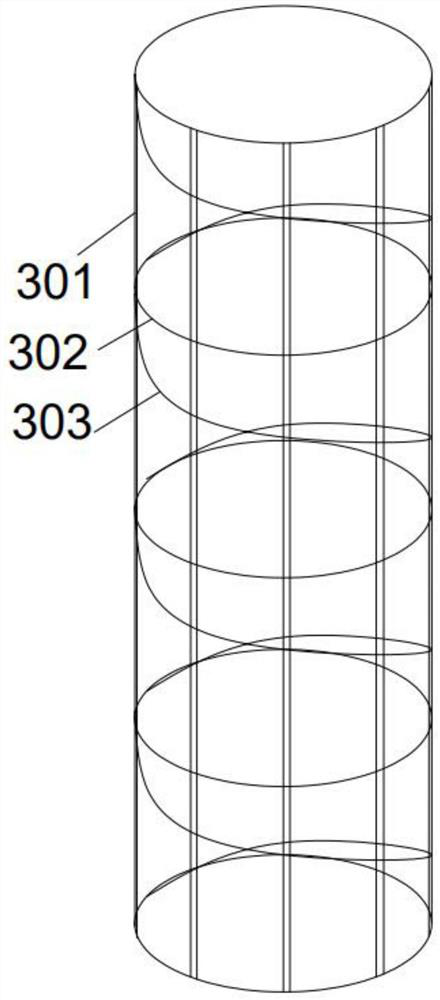

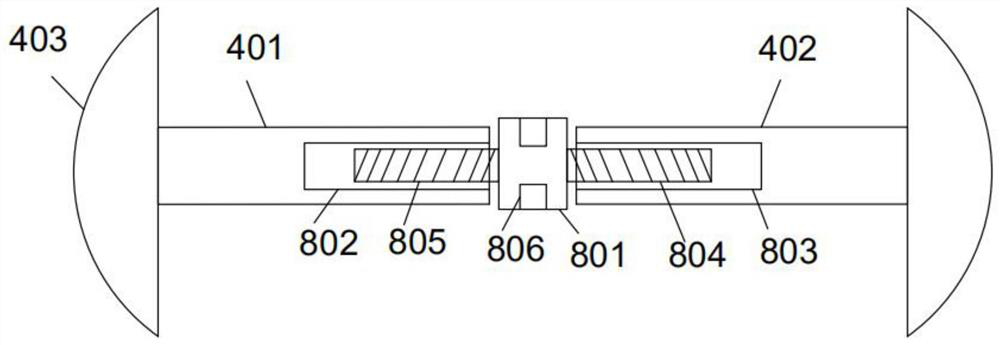

High-strength shock absorption and compression resistance type cement pipe column

InactiveCN112664723AEvenly planted reinforcement in support structureStrengthen traction and toughnessSleeve/socket jointsRigid pipesAgricultural engineeringStructural engineering

The invention discloses a high-strength shock absorption and compression resistance type cement pipe column. The cement pipe column comprises a concrete base layer, plant fiber filaments are arranged in the concrete base layer, a supporting framework is pre-planted in the concrete base layer and comprises main planting bars, annular planting bars are arranged on the outer sides of the main planting bars, spiral planting bars are arranged on the outer sides of the main planting bars, and compression resistance mechanisms are arranged in the concrete base layer. According to the cement pipe column, the spiral planting bars and the annular planting bars are fixed to the main planting bars, so that the blank area of the formed supporting framework after pouring is reduced, the supporting framework cannot deviate in the supporting process by means of the spiral structures of the spiral planting bars, so that pouring is more uniform, the cement pipe column is firmer due to the fact that the planting bars of the supporting structure are more uniform, the plant fiber filaments are mixed in the concrete base layer, so that the traction force and the toughness are enhanced, the surface is reinforced by a reinforcing grid layer, a coating layer is packaged, so that the surface is not liable to be damaged, scraps are not liable to fall from the surface, and an internal main body also cannot be damaged during collision.

Owner:泉州市元通科技服务有限公司

Precise circuit manufacturing method and circuit board

ActiveCN113068311AImprove pass rateEasy to producePrinted circuit secondary treatmentElectrical connection printed elementsEtchingCopper plating

Owner:SIHUI FUJI ELECTRONICS TECH

Moon cakes made by using truogx sinensis meat as filling

InactiveCN106305901AIncrease stickinessNot easy to drop crumbsDough treatmentBakery productsBiotechnologyDioscorea polystachya

The invention relates to moon cakes made by using truogx sinensis meat as a filling. The moon cakes comprise moon cake wrappers and a moon cake filling, wherein the moon cake wrappers are prepared from the following components in parts by weight: 46-57 parts of Chinese yam powder, 20-25 parts of black glutinous rice flour, 10-15 parts of bird meat, and 5-10 parts of chopped green onions, which are used as main materials, and also comprise 4-8 parts by weight of animal oil and fat; and the filling is prepared from the following components in parts by weight: 23-34 parts of truogx sinensis meat, 30-35 parts of jujubes, 10-15 parts of bee pollen, 4-7 parts of chopped green onions, and 3-5 parts of iodized edible refined salt, which are used as main materials. Compared with the prior art, people can smell fragrance when the moon cakes are unpacked, so that the appetite of people is attracted, the mouth feel is good, and the moon cake wrappers do not cause crumbs.

Owner:梁春林

Manufacturing method of interlayer cross line connecting structure, and circuit board

ActiveCN113015343ASmall footprintImprove qualityConductive pattern formationConductive material mechanical removalEngineeringNickel deposition

The invention discloses a manufacturing method of an interlayer cross line connecting structure, and a circuit board. The manufacturing method comprises the following steps: manufacturing a first connecting line groove and a first line groove which are communicated with each other on a first surface of an insulating substrate, and manufacturing a second connecting line groove and a second line groove which are communicated with each other on a second surface of the insulating substrate, wherein the depths of the first and second connecting wire grooves are greater than or equal to 1 / 2 of the thickness of the insulating substrate, and are smaller than 1 / 2 of the thickness of the insulating substrate, and the first and second connecting wire grooves are arranged in a crossed manner to form a through hole in an overlapping region of the two connecting wire grooves; carrying out copper deposition treatment on the insulating substrate, and removing a copper layer on the surface through a grinding plate; and then depositing a nickel layer through nickel deposition, and flattening the surface of the circuit through grinding to manufacture the precise circuit. The two crossed wire grooves are ablated through laser, and the through holes are formed in the overlapped area of the two crossed wire grooves, so that the area occupied by the through holes for interlayer connection is greatly reduced, and the method is suitable for interlayer connection of the IC support plate.

Owner:SIHUI FUJI ELECTRONICS TECH

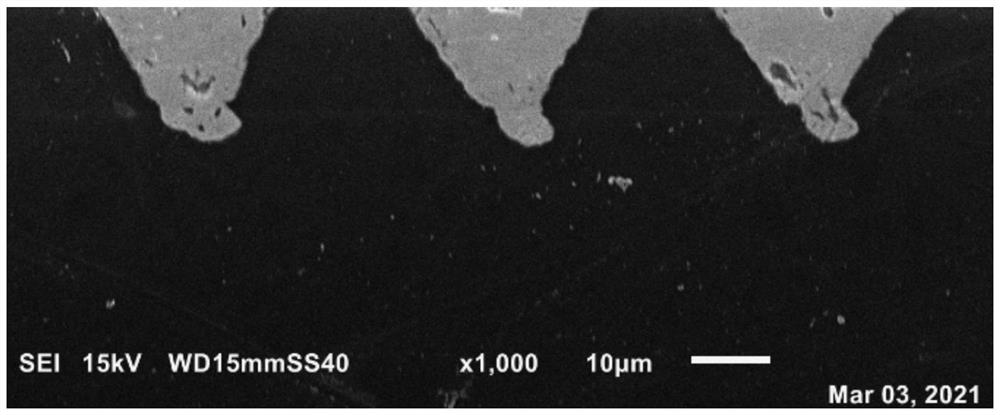

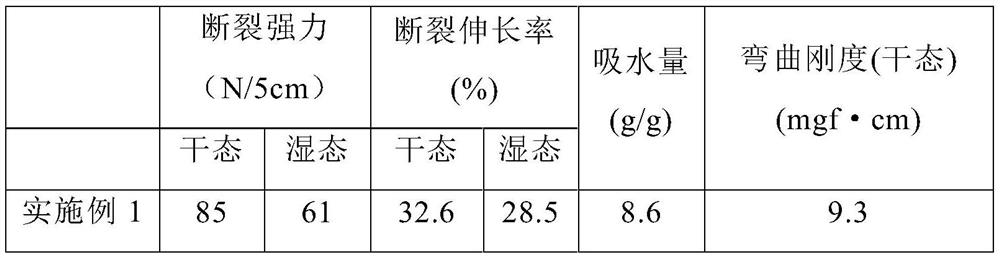

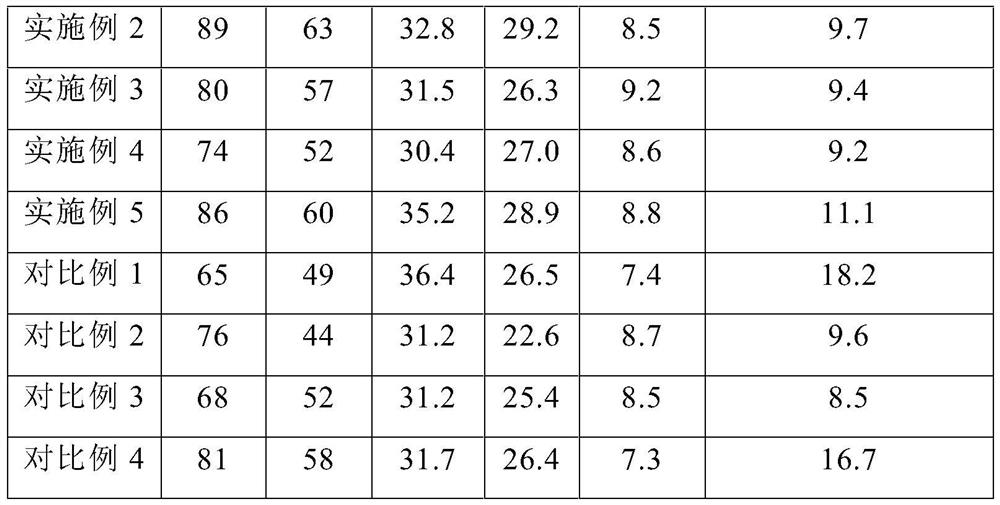

A double reinforced non-woven wiping material and its preparation method

The invention relates to a double-reinforced non-woven wiping material and a preparation method thereof. The double-reinforced non-woven wiping material is made of low-melting-point polyester fiber and viscose fiber respectively opened and carded into a web, and the two-layer web is first spunlace reinforced. It is obtained through thermal bonding and reinforcement; the raw materials for the preparation of the low-melting point polyester fiber include polyester and polyglycol, and the raw materials for the preparation of the polyester include neopentyl glycol and polyether polyol. It is prepared by mixing low-melting point polyester staple fibers and viscose fibers and then undergoing two reinforcement processes of spunlace and thermal bonding. In the preparation of polyester staple fibers, neopentyl glycol is added to polyester, so that polyester can be used in subsequent spinning. Under the high temperature condition of the silk process, it has certain hydrolysis resistance; polyether polyol is added to improve the softness of the obtained wiping material. Using a specific spunlace reinforcement and thermal bonding reinforcement process, the fibers are flexibly entangled and soft to the touch. The resulting wiping material has a firm structure, good durability and is not easy to shed.

Owner:ZHEJIANG WANGJIN NONWOVENS CO LTD

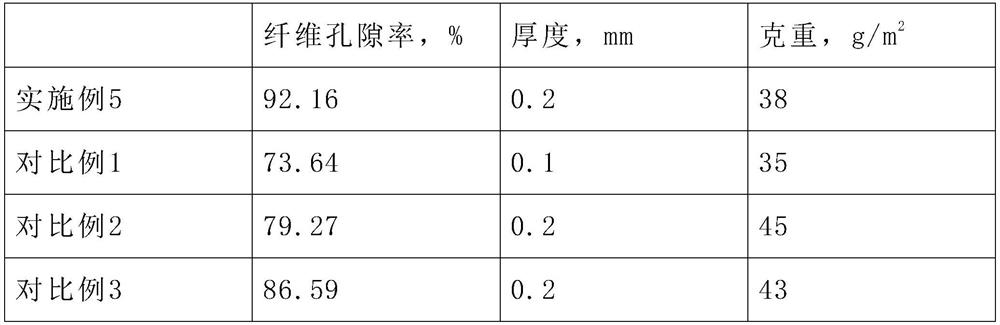

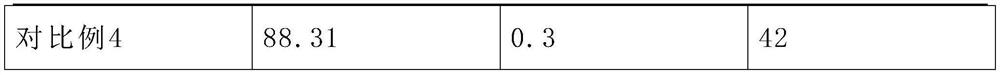

Preparation method of impact-resistant easily-degradable environment-friendly non-woven fabric

PendingCN112048829AImprove toughnessHigh impact strengthConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer sciencePolybutylene

The invention discloses a preparation method of an impact-resistant easily-degradable environment-friendly non-woven fabric. The preparation method of the impact-resistant easily-degradable environment-friendly non-woven fabric comprises the following steps that polylactic acid, epoxy resin, carbon nanotubes and acetone are mixed, ultrasonic treatment is carried out for 2-4 hours, ultrasonic poweris 300W-500W, the acetone is removed, a curing agent and montmorillonite are added, and reacting is carried out at 130DEG C-150DEG C for 10-20 minutes to obtain pretreated polylactic acid; the pretreated polylactic acid, polybutylene adipate-co-terephthalate resin, an inorganic filler and a plasticizer are uniformly mixed, twin-screw extrusion is carried out, and then sequential cooling, drying and crushing are carried out to obtain a premix; the premix is extruded and melted at the extruding and melting temperature of 160DEG C-168 DEG C, the temperature of the melt is adjusted to 185DEG C-190 DEG C, nascent fibers are sprayed through a 0.4mm-0.5mm spray head, the nascent fibers are stretched through air flow, the nascent fibers are uniformly laid into a fiber net, and the fiber net is bound through a 130 DEG C-140DEG C hot roller to obtain the impact-resistant easily-degradable environment-friendly non-woven fabric.

Owner:温岭市妮珂芙服饰有限公司

Transfusion container sealing cover with easily-torn sealing membrane transfusion pipe and drug feeding pipe

ActiveCN101804006BReduce manufacturing costNot easy to drop crumbsInfusion devicesPharmaceutical containersCatheterBottle

The invention relates to a transfusion container sealing cover with an easily-torn sealing membrane transfusion pipe and a drug feeding pipe, belonging to a liquid inlet and outlet pipeline and a pipeline sealing device of a transfusion bottle (bag). The easily-torn sealing membrane transfusion pipe and the drug feeding pipe are fixed on the same surface of a cover bottom sheet of a cover body inparallel; the easily-torn membrane transfusion pipe comprises an easily-torn sealing membrane transfusion needle guide pipe and an easily-torn sealing membrane; the drug feeding pipe comprises a drugfeeding pipe body, a gasket, a gasket fixing ring and an easy-open cover, the gasket is arranged on a gasket membrane, and the gasket fixing ring is arranged on the gasket; and the cover body comprises the circular cover bottom sheet, a hollow cylinder formed by connecting the side walls of the cover, and a cylinder welding ring formed by outwards extending the edge of the hollow cylinder. The invention has the advantages that double-pipe combiner can realize two functions of drug feeding and transfusion, and has difficult scrap dropping and easy puncture in the process of transfusing puncture; and the transfusion container sealing cover also has lower production cost.

Owner:SICHUAN KELUN PHARMA CO LTD

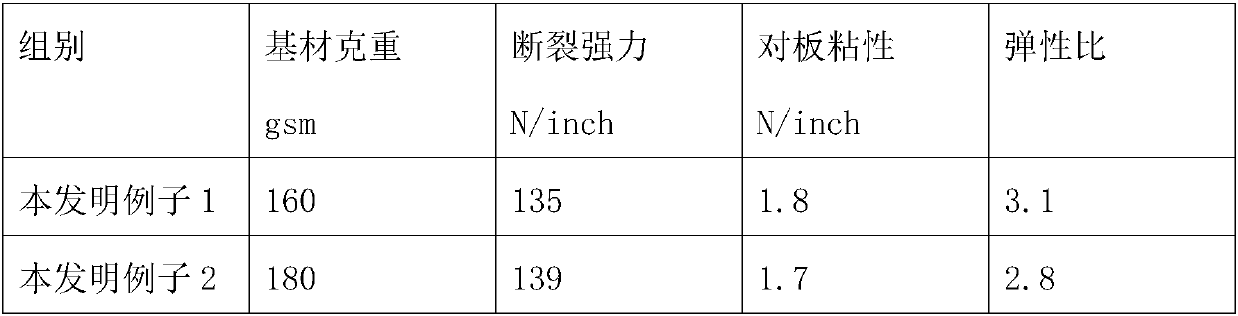

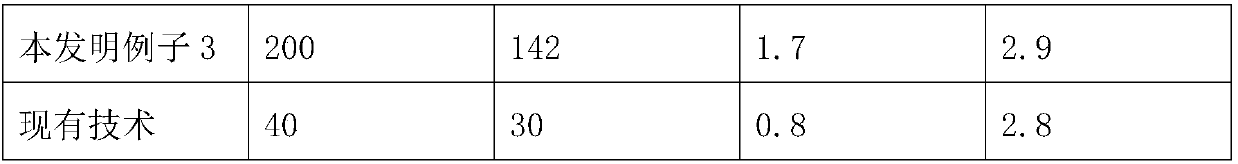

Pretreatment method for full-cotton heavy type self-adhering bandage

InactiveCN107638249AIncrease the amount of glueImprove adhesionAdhesive dressingsYarnPretreatment method

The invention discloses a pretreatment method for a full-cotton heavy type self-adhering bandage. The pretreatment method includes the steps that a, during preparation of a substrate, the substrate isselected to be made of pure cotton materials, and a selected gram weight ranges from 160 gsm to 200 gsm for the pure cotton materials; b, during making of the substrate, the substrate is set to be woven fabric, spandex filaments are arranged, the spandex filaments are coated to form stretch yarns, and the multiple stretch yarns are arranged on the surface of the substrate; c, during preparation of a padding reagent, the padding reagent is composed of, by weight, 2-4 parts of mixtures of methyl acrylate and ethyl acrylate, 1-2 parts of water and 0.05-0.2 part of cross-linking agent, wherein the proportion of the methyl acrylate to the ethyl acrylate is 1:1 during mixing; d, during finishing, the padding reagent in the step C is adopted for finishing the substrate in the mode of padding.

Owner:JUNTECH HEALTHCARE MATERIALS

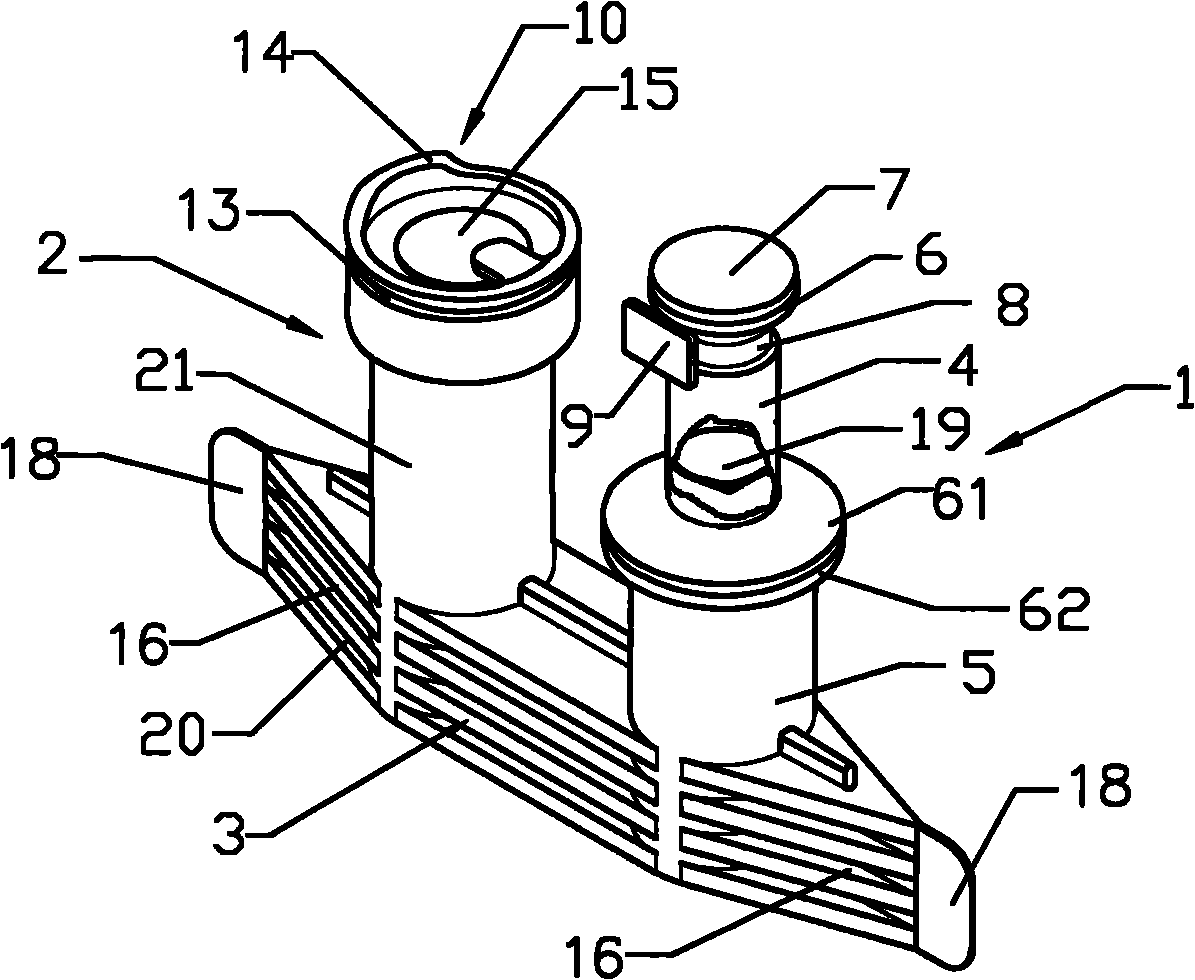

Transfusion container sealing cover with side-pull type transfusion pipe

ActiveCN101804001BReduce manufacturing costNot easy to drop crumbsInfusion devicesPharmaceutical containersCatheterEngineering

The invention relates to a transfusion container sealing cover with a side-pull type transfusion pipe, belonging to a liquid inlet and outlet pipeline of a transfusion bottle (bag) and a pipeline sealing device, namely an accessory of a transfusion container. The side-pull type transfusion pipe is communicated with a hole in the center of a cover body and is formed by connecting a side-pull type transfusion needle guide pipe and a sealing sheet; a cavity of the side-pull type transfusion needle guide pipe is provided with a sealing membrane, the outer wall is provided with an easily-pull ringand a pull sheet; and the cover body comprises a circular thin sheet, a hollow cylinder and a welding ring. The transfusion container sealing cover with the side-pull type transfusion pipe has the advantages of difficult scrap dropping and easy puncture in the process of transfusing puncture as well as lower production cost; and the easily-pulling structure of the easily-pull ring is convenient for transfusion operation.

Owner:SICHUAN KELUN PHARMA CO LTD

A method for making an interlayer cross-wire connection structure and a circuit board

ActiveCN113015343BSmall footprintImprove qualityConductive pattern formationConductive material mechanical removalEngineeringNickel deposition

The invention discloses a manufacturing method and a circuit board of an interlayer cross-wire connection structure. The manufacturing method comprises the following steps: manufacturing a first connecting wire slot and a first circuit connected to each other on a first surface of an insulating base material The groove is made on the second surface of the insulating base material to connect the second connecting wire groove and the second circuit groove. The depth of the first and second connecting wire grooves is ≥ 1 / 2 of the thickness of the insulating base material. The depth of the second line groove is less than 1 / 2 of the thickness of the insulating base material; the first and second connecting line grooves are crossed to form a through hole in the overlapping area of the two connecting line grooves; The copper layer on the surface is removed from the board; then a layer of nickel is deposited by immersion nickel, and the surface of the circuit is flattened by grinding to obtain a precision circuit. The invention adopts the method of laser ablating two intersecting wire grooves and forming through holes in the overlapping area of the two intersecting wire grooves, so that the area occupied by the through holes connected between the layers is greatly reduced, and is suitable for the interlayer of the IC carrier board. connect.

Owner:SIHUI FUJI ELECTRONICS TECH

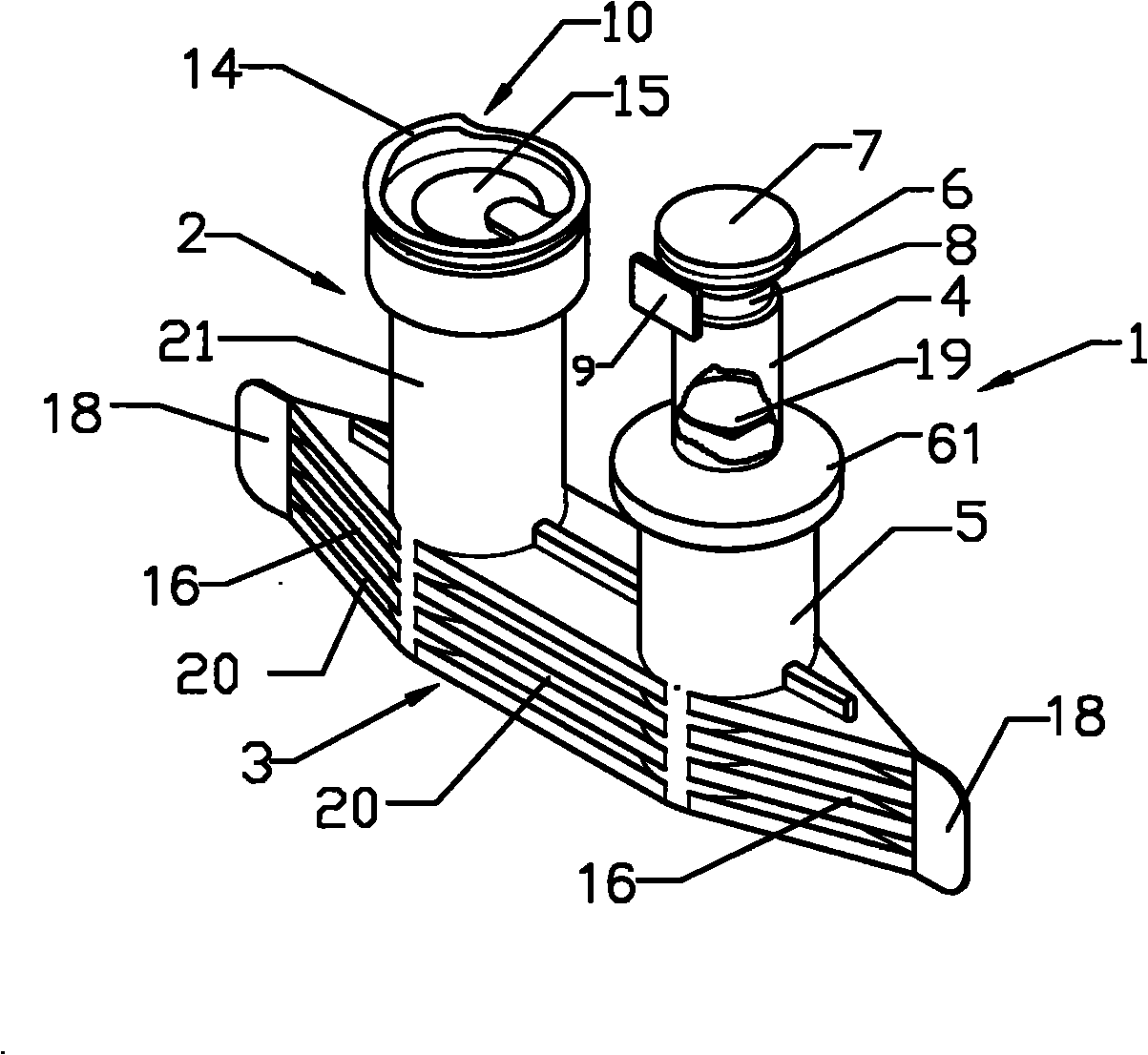

Transfusion container sealing cover with side-pull type transfusion pipe and drug feeding pipe

ActiveCN101804004BReduce manufacturing costNot easy to drop crumbsInfusion devicesPharmaceutical containersDouble tubeEngineering

The invention relates to a transfusion container sealing cover with a side-pull type transfusion pipe and a drug feeding pipe, belonging to a liquid inlet and outlet pipeline of a transfusion bottle (bag) and a pipeline sealing device. The side-pull type transfusion pipe and the drug feeding pipe are fixed on the same outer surface of a cover body basically in parallel; the side-pull type transfusion pipe comprises a side-pull type transfusion needle guide pipe and a sealing sheet; the drug feeding pipe comprises a drug feeding pipe body, a gasket, a gasket fixing ring and an easily-pull cover, wherein the gasket is arranged on a gasket membrane, and the gasket fixing ring is arranged on the gasket; the cover body comprises a cover bottom sheet, a hollow cylinder and a cylinder welding ring, wherein the hollow cylinder is formed by connecting the side walls of the cover, and the cylinder welding ring is formed by outwards extending the edge of the hollow cylinder. The invention has the advantages that a double-pipe connector can realize two functions of drug feeding and transfusion, and the transfusion container sealing cover has difficult scrap dropping and easy puncture in the process of transfusing puncture; and the transfusion container sealing cover also has lower production cost.

Owner:SICHUAN KELUN PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com