Pretreatment method for full-cotton heavy type self-adhering bandage

A heavy-duty, self-adhesive technology, applied in viscous dressings, dressings, etc., can solve the problems of unsuitable medical heavy-duty protective gear and low strength, and achieve the effects of improving aesthetics, improving breaking strength, and eliminating bulkiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention are clearly and completely described below. Obviously, the described embodiments are part of the embodiments of the present invention, not all Example.

[0023] The pretreatment method of the all-cotton heavy-duty self-adhesive bandage in the present embodiment comprises the steps:

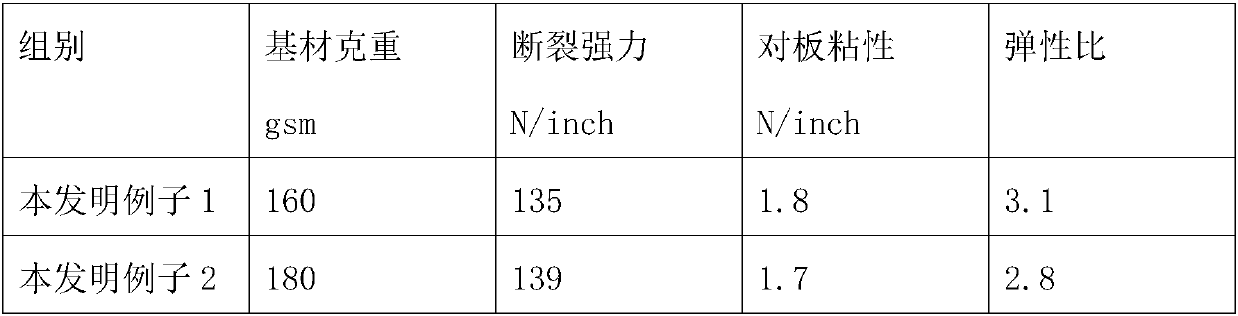

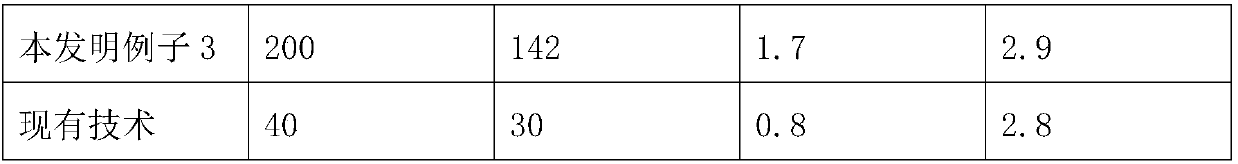

[0024] A preparation of the base material: the base material is made of pure cotton material, and the weight of the pure cotton material is selected from 160 to 200gsm; Thick, so that the self-adhesive bandage can meet the high-strength requirements;

[0025] Production of B base material: the base material is set as a woven fabric, so that the fabric texture is formed on the base material to improve the aesthetics, and the spandex yarn is configured, and the spandex yarn is covered with a process to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com