Infusion bag part with fusiform seat, side pull infusion tube and gasket ring dosing tube

A technology for infusion tubes and dosing tubes, applied in the field of double-tube infusion bag accessories, which can solve the problems of easy chip loss, high puncture resistance, and increased chip loss, so as to reduce the probability of leakage, simplify infusion operations, and reduce welding parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

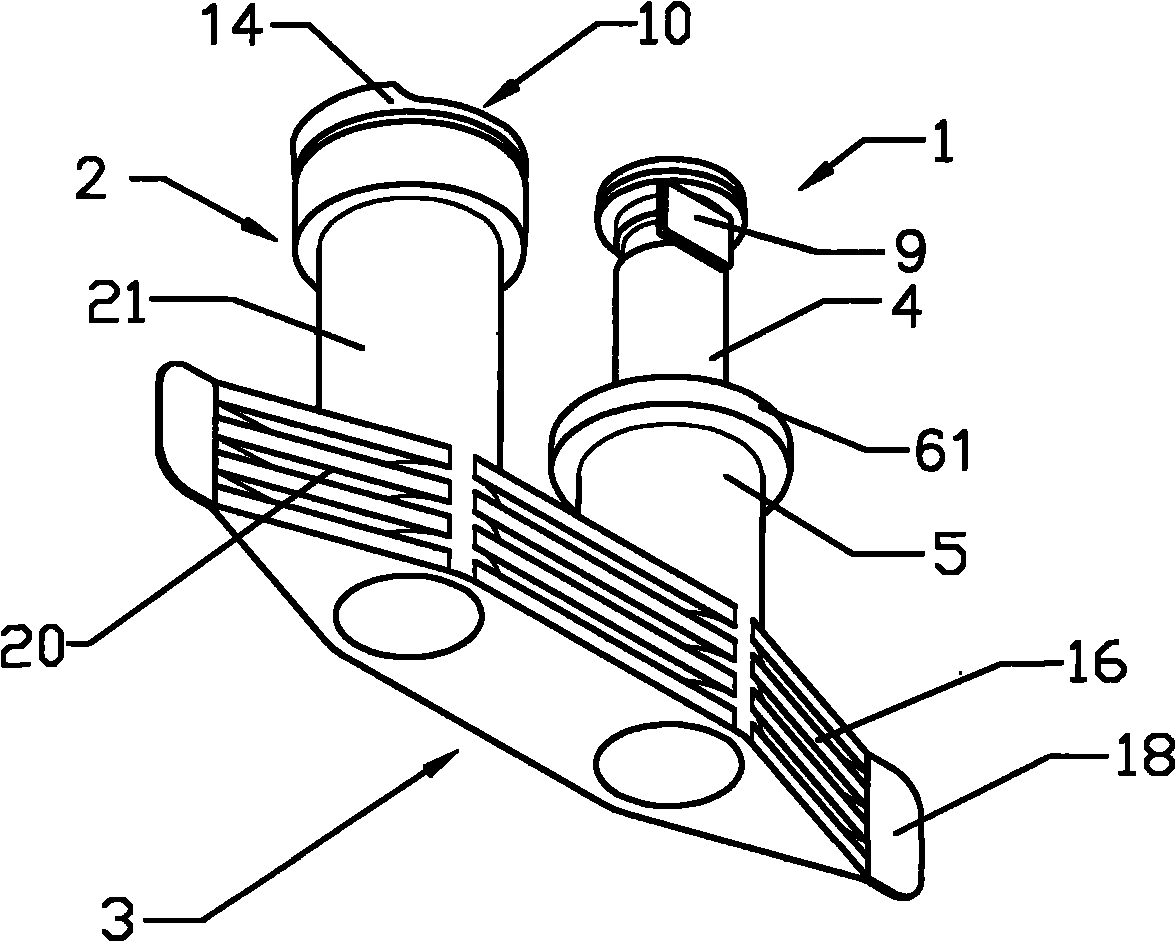

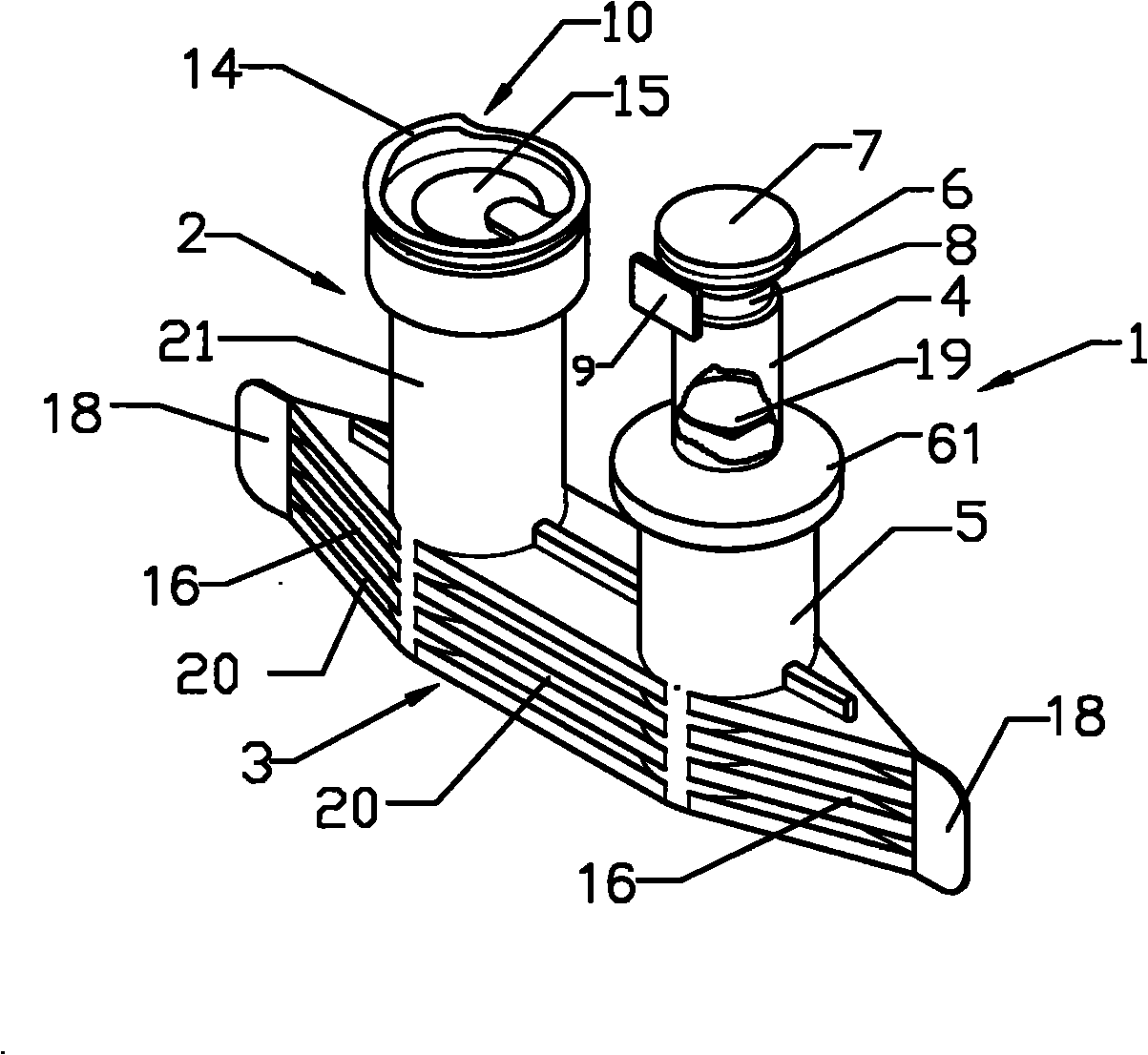

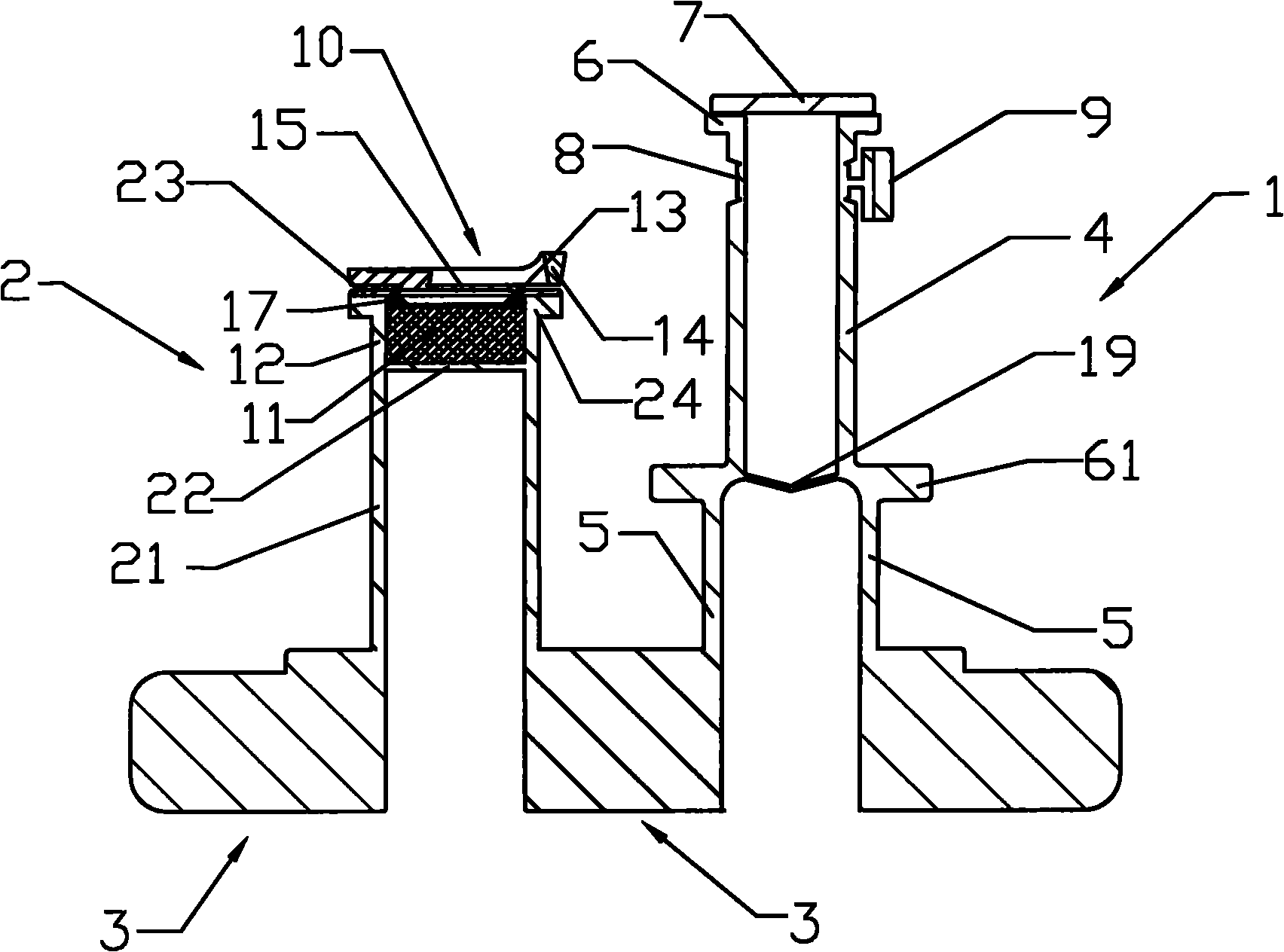

[0027] Example 1. Infusion bag accessories with side-pull infusion tube and gasket ring dosing tube with shuttle-shaped seat

[0028] Use polypropylene pellets to connect the connecting tube body 5 of the side-pull infusion tube 1 and the 4 part of the side-pull infusion needle catheter, the dosing tube body 21 of the dosing tube 2 and the 12 part of the concave gasket groove ring, and the shuttle tube The three parts of the body base 3 are injection molded into an integral part at one time. The tube body of the side-pull infusion tube 1 and the tube body of the dosing tube 2 are located on the same surface of the spindle-shaped tube body seat 3 and are basically parallel. The distance between the outer walls of the side-pull infusion tube 1 and the dosing tube 2 is 16mm. The sealing sheet 7, the easy-open lid 10 and the gasket fixing ring 17 are respectively injection molded with polypropylene pellets. The gasket 11 is made of polyisoprene.

[0029] The sealing sheet 7 and the ...

Embodiment 2

[0053] Embodiment 2 The main structure is the same as that of Embodiment 1, but the shuttle-shaped tube seat 3 used for connecting with the infusion bag film is provided with a plurality of recessed cells 20 on both sides.

Embodiment 3

[0054] Embodiment 3, the main structure is the same as embodiment 1, but the inner diameter of the connecting tube body 5 is 5.0 mm, which is the same as the inner diameter of the side-pull infusion needle catheter 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com