Transfusion container sealing cover with top-pull type transfusion pipe and drug feeding pipe

An infusion container, top-pull technology, applied in the field of medical infusion packaging, can solve the problems of gaskets and inner covers that are easy to chip, high production cost, and large puncture resistance, and achieve low production cost, not easy to drop chips, and easy to puncture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

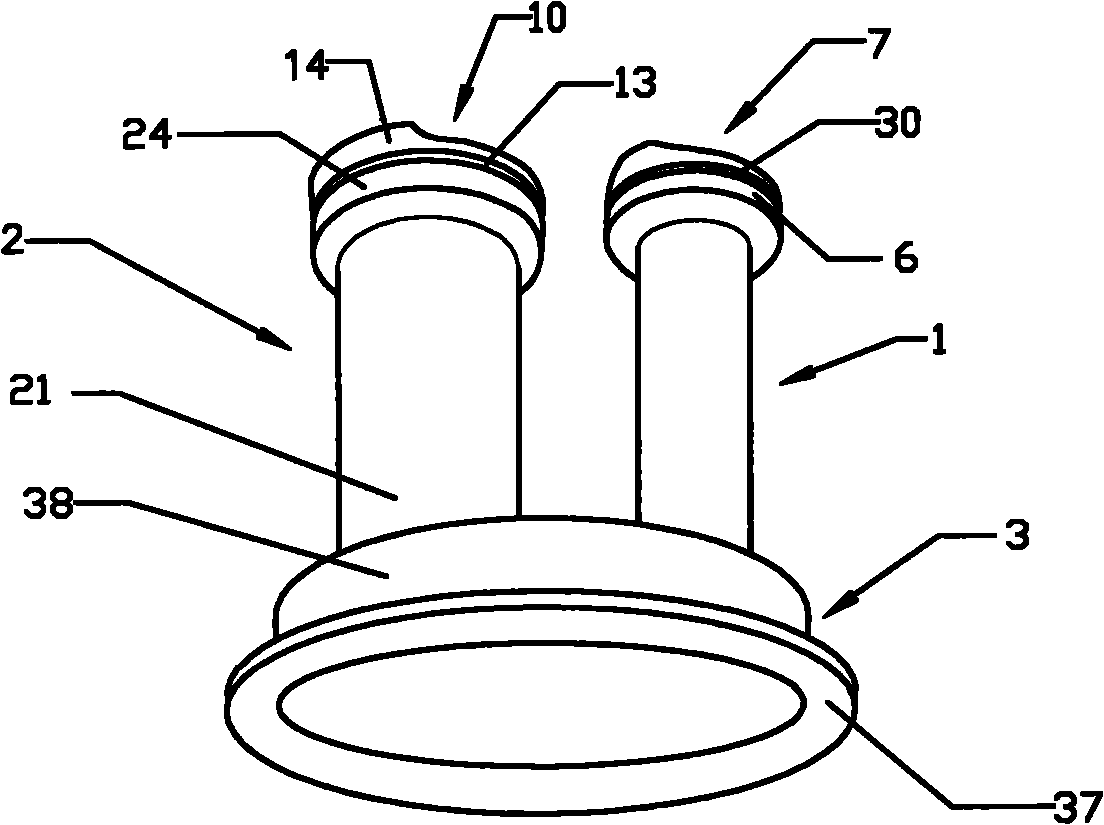

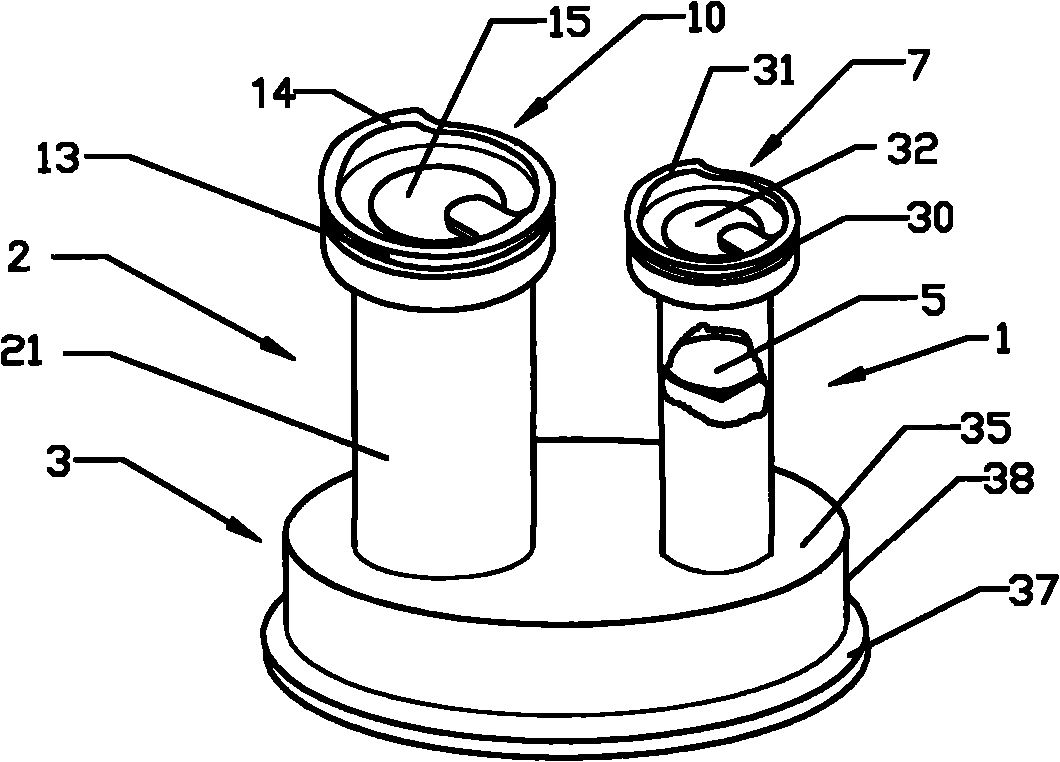

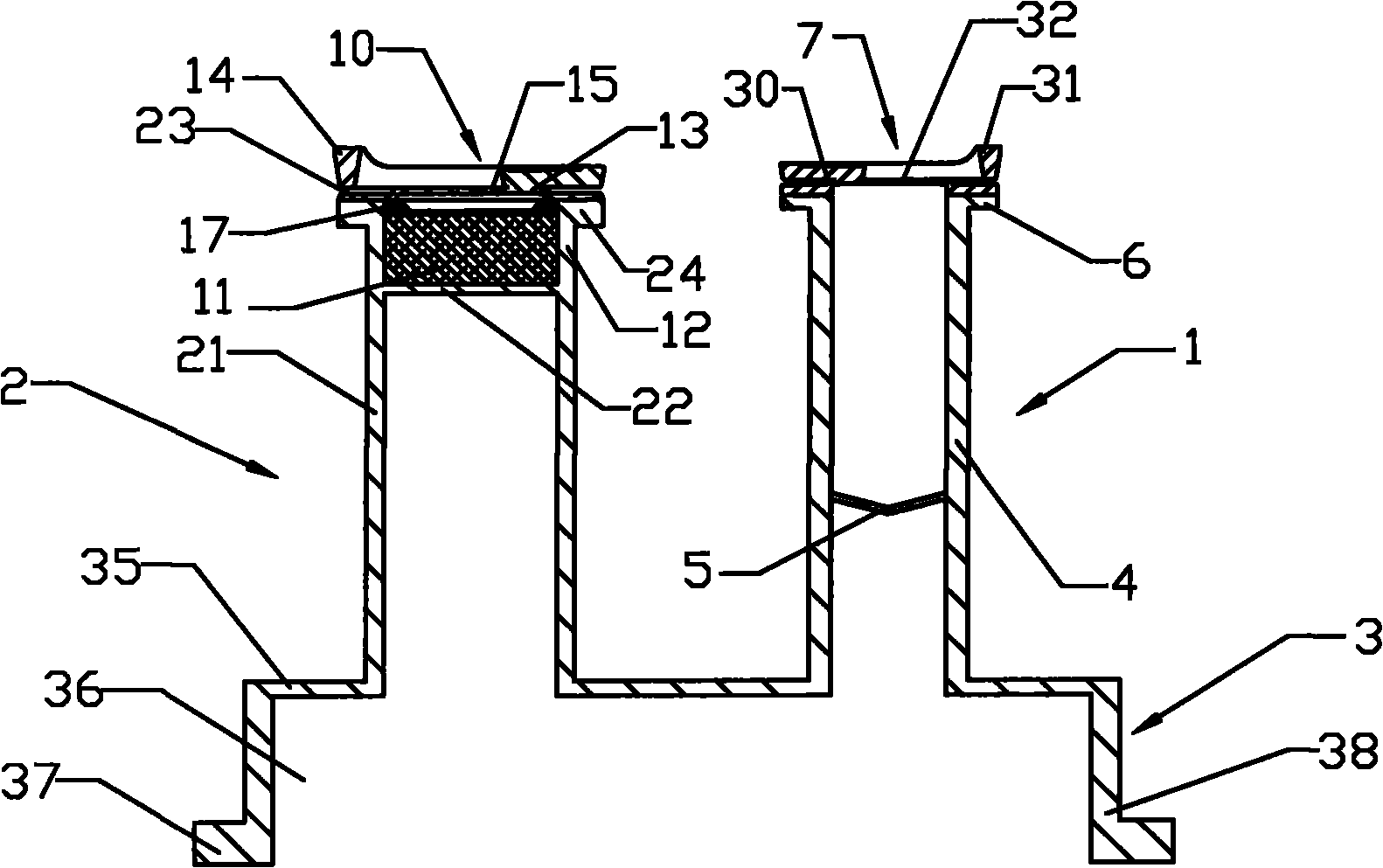

[0021] Embodiment 1, the infusion container seal cover of band top-pull infusion tube and dosing tube

[0022] The main part of the sealing cover is injection-molded with polypropylene pellets at one time, and the main part includes the cover body 3, the top-pull infusion needle catheter part 4 of the top-pull infusion tube 1, the dosing tube body 21 of the dosing tube 2 and the inner cavity Empty 12 sections. The top-pull infusion tube 1 and the dosing tube 2 are located on the same surface of the bottom cover sheet 35 and are basically parallel, and the distance between the outer walls of the top-pull infusion tube 1 and the dosing tube 2 is 6mm. The top-pull sealing cover 7, the easy-open cover 10 and the gasket fixing ring 17 are respectively injection-molded with polypropylene pellets. Spacer 11 is made of polyisoprene.

[0023] The top-pull sealing cover 7 is thermally sealed with the welding ring 6 connected to the top cover; the gasket 11 is placed in the recessed in...

Embodiment 2

[0046] The main structure is the same as that of Embodiment 1, but the sealing diaphragm 5 is a plane, and the bottom cover sheet 35 is oval.

Embodiment 3

[0048] The main structure is the same as that of Embodiment 1, but the thickness of the gasket 11 is 6.0 mm, and the thickness of the gasket diaphragm 22 is 1.0 mm.

[0049] Embodiment 3,

[0050] The main structure is the same as in Embodiment 1, but the height of the hollow cylinder 36 is 6.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com