A double reinforced non-woven wiping material and its preparation method

A wiping material and non-woven technology, which is applied in the direction of non-woven fabrics, textiles, and papermaking, can solve the problems of insufficient flexibility, insufficient strength, and insufficient durability of wiping materials, and achieve temperature optimization of water pressure and thermal bonding , soft touch, improved breaking strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

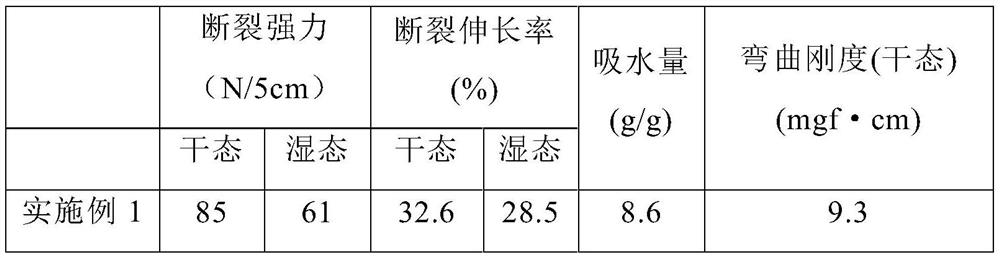

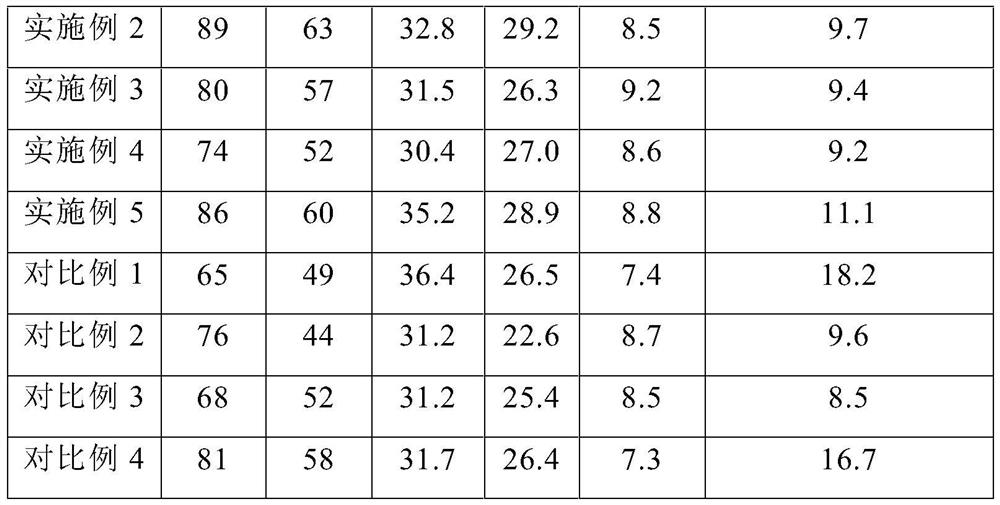

Examples

preparation example 1

[0042] Add 100 mole parts of terephthalic acid, 80 mole parts of butanediol, and 20 mole parts of neopentyl glycol into the reactor, and prepolymerize at 230°C for 1 hour at a relative pressure of -0.05MPa; then add 5 moles of Parts polyoxypropylene trihydric alcohol, polycondensation catalyst Sb of monomer (the sum of terephthalic acid, butanediol and neopentyl glycol) 0.2wt% 2 o 3 , at 250°C, 0.1MPa polycondensation for 5h, the acid value of the detection system is lower than 10mg KOH / g, stop the reaction, filter to remove impurities, pass through a casting belt, use a pelletizer to slice the polyester, and measure the viscosity average of the obtained polyester The molecular weight is 13200g / mol, and the melting point is 105-110°C.

[0043] The obtained 100 parts of polyester chips and 7 parts of PEG500, 0.8 parts of nano-silver, 1.1 parts of polyvinylpyrrolidone, 0.9 parts of antioxidant 2246 are added to a twin-screw extruder for extrusion granulation. The process of the...

preparation example 2

[0046] Other steps and conditions are the same as in Preparation Example 1, except that the polyoxypropylene triol is replaced by polyoxypropylene tetraol in an equimolar portion, and the viscosity-average molecular weight of the obtained polyester is 16900 g / mol, and the melting point is 110-115°C.

preparation example 3

[0048] Other steps and conditions are the same as Preparation Example 1, the difference is that the amount of each raw material becomes 100 molar parts of terephthalic acid, 70 molar parts of butanediol, 25 molar parts of neopentyl glycol, and 10 molar parts of polyoxypropylene trihydric alcohol , the viscosity-average molecular weight of the finally obtained polyester is 18400g / mol, and the melting point is 108-110°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com