Special electronic paper front light structure

A technology of electronic paper and optics, applied in optics, nonlinear optics, instruments, etc., can solve the problems of expensive mold opening, increasing the surface thickness of electronic paper display modules, and the size cannot be changed at will

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

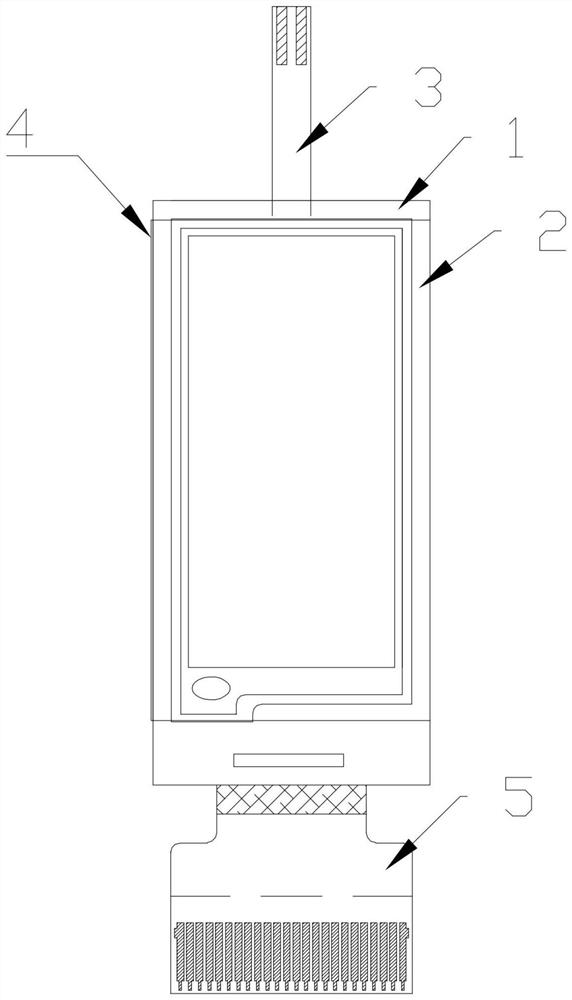

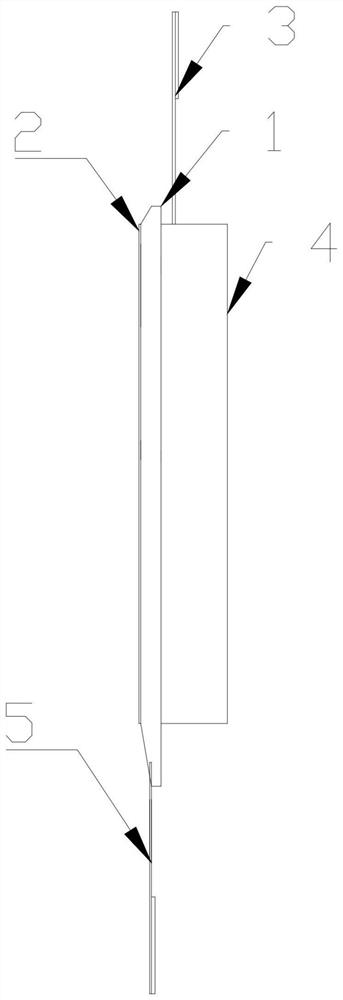

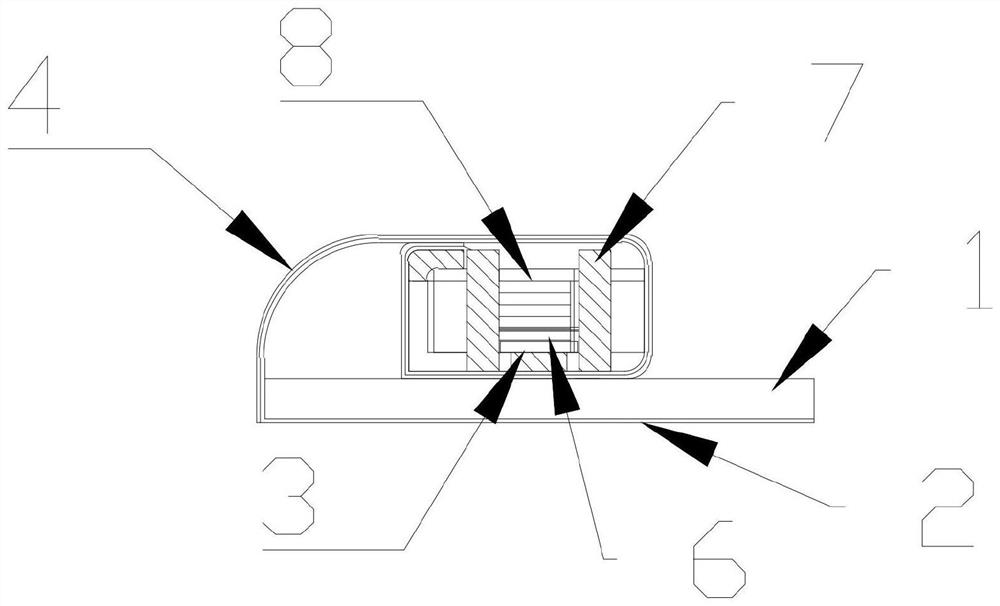

[0029] Such as Figure 1-13 As shown, an electronic paper front light structure includes a flexible optical light guide film (2), an electronic paper display module (1), a fixed iron frame (7), a toothed light guide plastic frame (8), and an LED lamp ( 6), LED light bar FPC (3), aluminum foil reflective film (4).

[0030] The front end of the flexible optical light guide film (2) is bonded to the display surface of the electronic paper display module (1) through OCA glue, the outside of the rear end is bonded to the aluminum foil reflective film (4), and the flexible optical light guide film (2) The rear end also wraps the fixed iron frame (7), the tooth-shaped light guide plastic frame (8) and the LED lamp (6) inside, and fixes it on the back of the electronic paper display module (1) after wrapping. The fixed iron frame (7) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com