Magnetic suspension motor without thrust disc and work method thereof

A magnetic levitation, no thrust technology, applied in the direction of holding devices, electrical components, electromechanical devices, etc. with magnetic attraction or thrust, can solve the problem of volatile magnetism, inconvenient assembly or disassembly of the rotor core shaft of radial magnetic levitation bearings, permanent magnet body temperature, etc. To solve problems such as rise and large, to achieve smooth flow channels, solve the problem of easy loss of magnetism, and have a good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

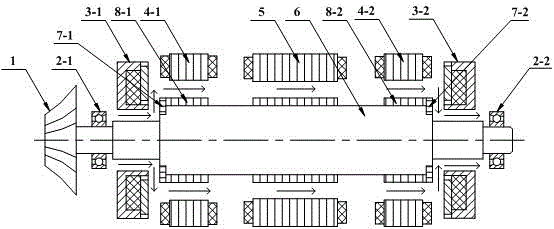

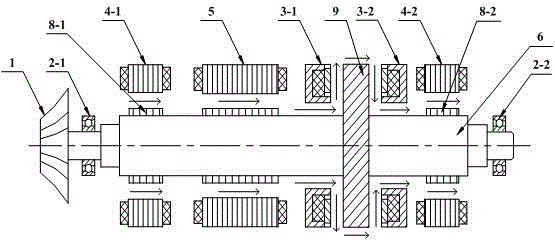

[0018] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] The invention discloses a magnetic levitation motor without a thrust disk and a working method thereof, and relates to the technical field of magnetic levitation motors. The magnetic suspension motor structure includes a working machine 1, a left protective bearing 2-1, a left axial magnetic suspension bearing 3-1, a left radial magnetic suspension bearing 4-1, a high-speed motor 5, a right radial magnetic suspension bearing 4-2, and a right axial magnetic suspension bearing 4-1. Magnetic suspension bearing 3-2, right protection bearing 2-2, rotor core shaft 6. The rotor mandrel 6 has a symmetrical structure, and it consists of a middle section, a second left section and a second right section located outside the middle section, and a third left section and a third right section located outside the second left and right sections. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com