Rapid and automatic winding machine for motor processing

An automatic winding machine, fast technology, applied in the direction of electric components, manufacturing motor generators, coil manufacturing, etc., can solve the problems of long time consumption, affecting the production efficiency of motors, cumbersome installation and disassembly of stators, etc., to reduce wear and tear, and simple structure , the effect of fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

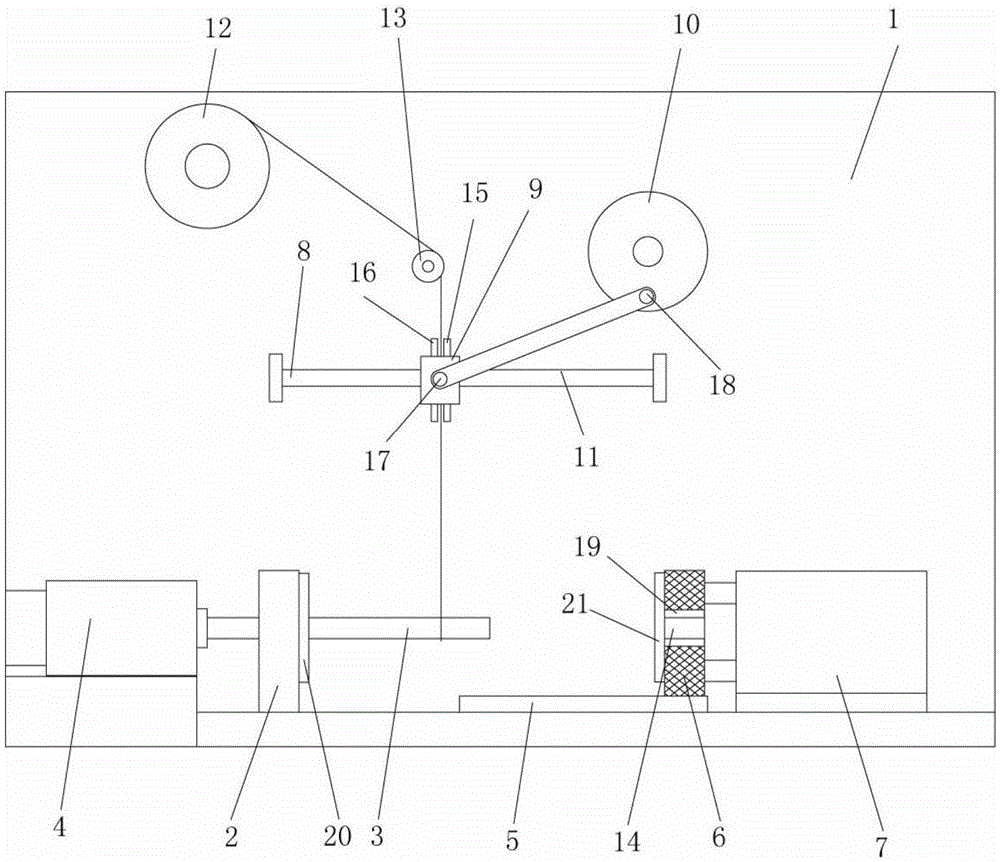

[0021] like figure 1 As shown, a fast automatic winding machine for motor processing includes a frame 1, a fixed seat 2, a winding shaft 3, a motor 4, a sliding track 5, a moving seat 6, a cylinder 7, a fixed rod 8, a sliding block 9, a rotary Wheel 10, connecting rod 11, pay-off wheel 12, guide wheel 13, fixed seat 2 is installed on the frame 1, the middle part of bobbin 3 is worn on the fixed seat 2, motor 4 is fixed on one side of the fixed seat 2 and It links to each other with an end of bobbin 3, and slide rail 5 is installed on the frame 1, and the lower end of movable seat 6 is installed on the slide rail 5 and it is positioned at the other side of fixed seat 2, and the middle part of movable seat 6 is provided with and around The other end of the spool 3 is opposite to the opening 14, the cylinder 7 is installed on the frame 1 and it is connected with the moving seat 6, the fixed rod 8 is installed on the frame 1 and it is arranged in parallel above the bobbin 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com