Printed circuit board perforating device

A technology for printed circuit boards and punching devices, which is applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as inability to clean the holes and slag, and achieve the effect of saving processing time and facilitating storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below by means of specific embodiments:

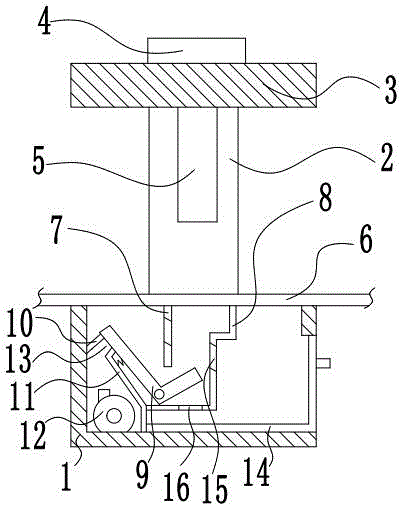

[0033] The reference signs in the drawings of the description include: support base 1, vertical arm 2, cross arm 3, motor 4, drill bit 5, PCB board 6, left side board 7, right side board 8, swing rod 9, slant board 10, Z-shaped plate 11, blower 12, air outlet 13, drawer 14, return air hole 15, leakage hole 16.

[0034] like figure 1 As shown, the printed circuit board punching device includes a support base 1 at the bottom and a suspension arm installed on the support base 1 . The suspension arm includes a vertical arm 2 perpendicular to the support base 1 and a cross arm 3 vertically connected to the top of the vertical arm 2 . The cross arm 3 is equipped with a motor 4 and a drill bit 5 connected with the motor 4 and passing through the cross arm 3 to extend downwards for punching a PCB board 6 . The support base 1 is a hollow structure with an upper end opening, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com