Turbocharger structure for vehicle

A turbocharger, vehicle technology, applied in machine/engine, combustion engine, internal combustion piston engine, etc., can solve problems such as disadvantage, reduced engine efficiency, impact on engine performance and mileage fuel consumption, etc., to ensure combustion stability, emission reduction, etc. The effect of minimizing gas interference, improving performance and mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, exemplary embodiments of the present disclosure will be described in detail with reference to the accompanying drawings.

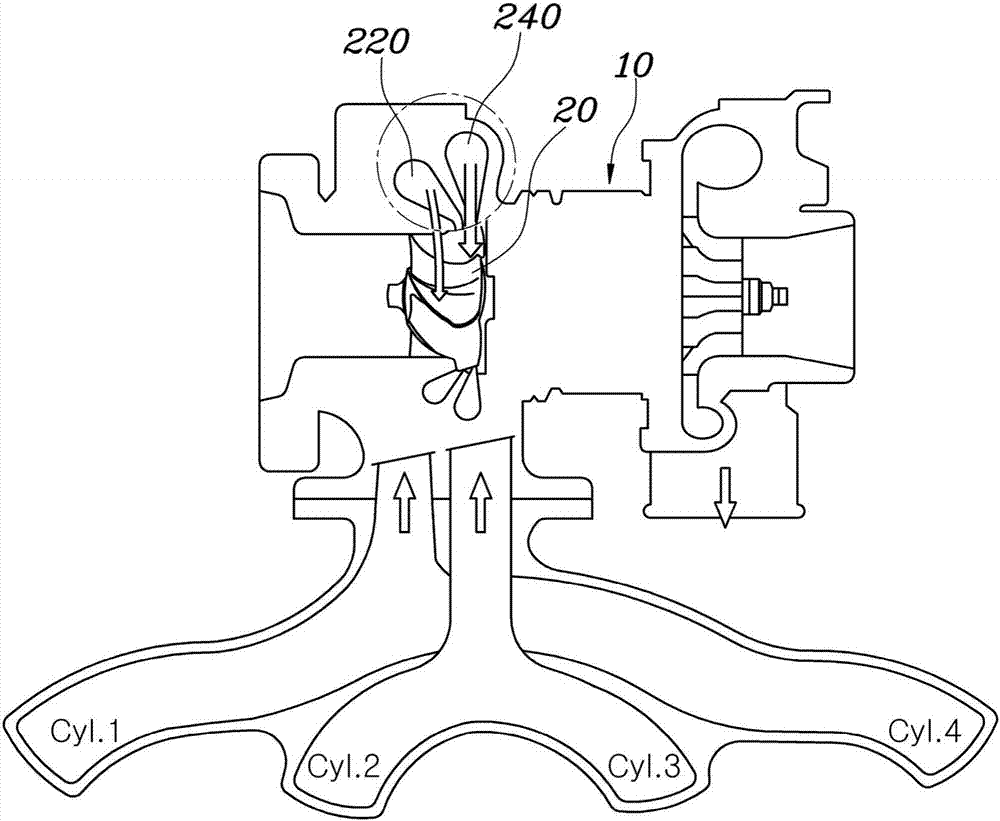

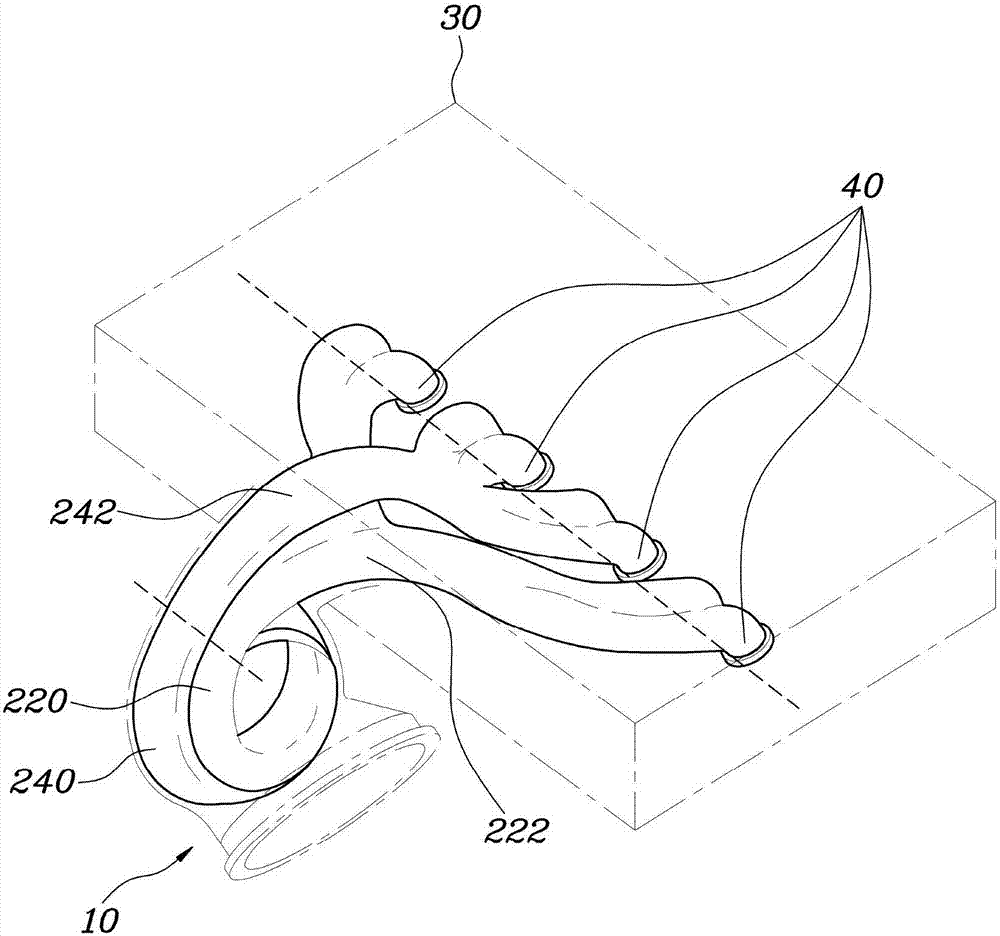

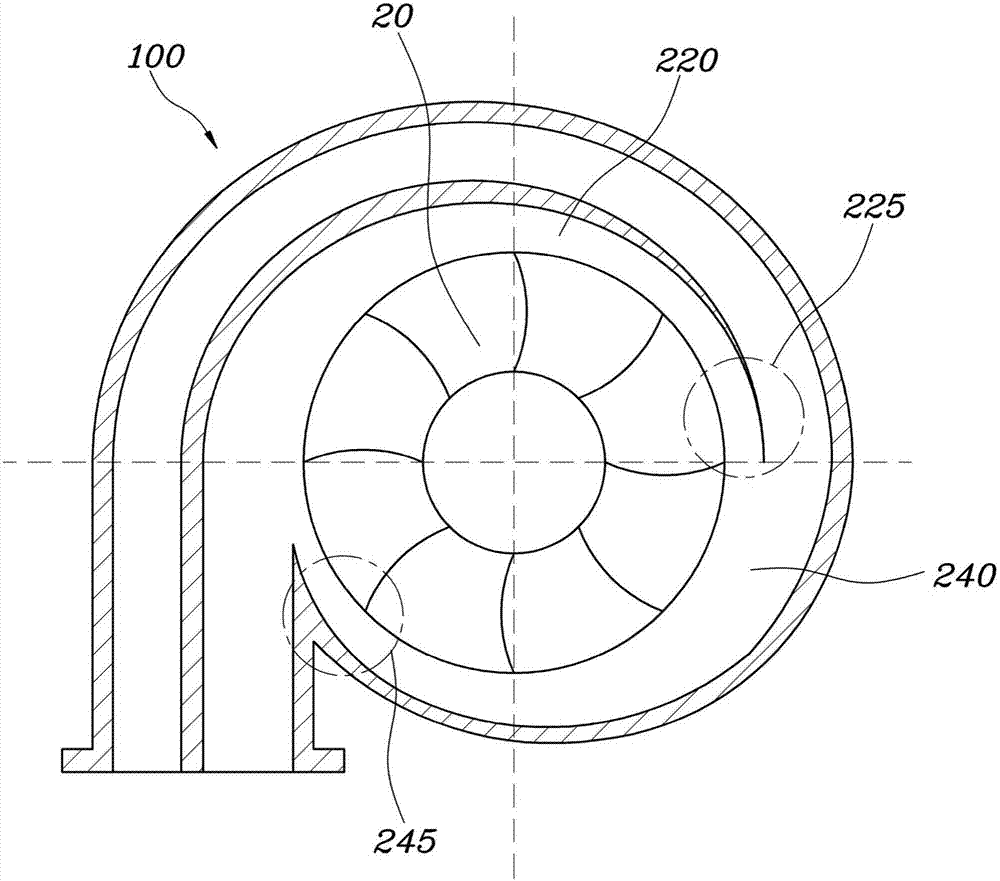

[0022] Such as Figure 1 to Figure 3 As shown, the turbocharger structure 100 for a vehicle according to the present disclosure may include: a turbine 20 rotated by exhaust gas; a first scroll 220 communicated with the exhaust port 40 of the engine block 30 to allow the exhaust gas to flow Among them, the first scroll 220 may be configured to surround the turbine 20 by extending along the circumferential direction of the turbine 20, and may be provided at an end thereof with an opening 225 for discharging exhaust gas to the turbine 20; The scroll 240 communicates with the exhaust port 40 of the engine block 30 to allow exhaust gas to flow thereinto, and the second scroll 240 may be configured to surround the turbine 20 together with the first scroll 220 by extending along the circumferential direction of the turbine 20 20, and may be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com