Hot-press waxing machine for fruit production

A waxing machine, fruit technology, applied in the protection of fruits/vegetables with a protective coating, application, food processing, etc., can solve the problems of low waxing flatness, high cost, low mechanical efficiency, etc., to extend the working time. , The effect of small mechanical loss and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

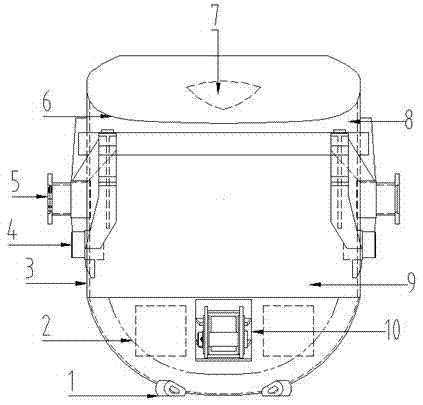

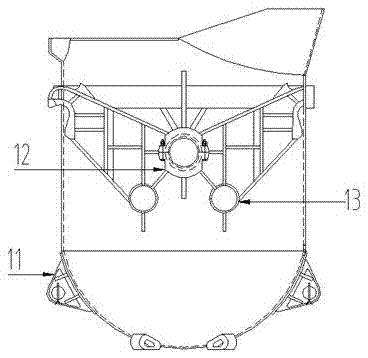

[0016] like Figure 1-Figure 2 As shown, a hot-press waxing machine for fruit production includes a base 1, a pressure sealer 4, a flat shaft 8 and a driving wheel 11, and a switch 2 is installed above the base 1 to adjust the current. There is a heat conduction sheet 3 above the door 2, which can conduct heat conduction. The heat conduction sheet 3 is arranged between the switch 2 and the pressure sealer 4, which can perform rapid sealing and pressure. A wax dropper 5 is arranged above the pressure sealer 4, which can be used for fruit Carry out rapid wax dripping, a secondary driving wheel 6 is installed above the wax dropping device 5, which can increase the speed of the driving wheel, and a motor 7 is arranged above the secondary driving wheel 6, which can generate electricity, and the motor 7 is installed on the top of the flat shaft 8 to improve Stability of the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com