Novel inner composite bottom pot

A double-bottom pot, a new type of technology, is applied to special materials for cooking utensils, cooking utensils, household utensils, etc. It can solve the problems of pots that cannot be used, deformed, and double-bottom cracks, and achieve the effect of avoiding scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

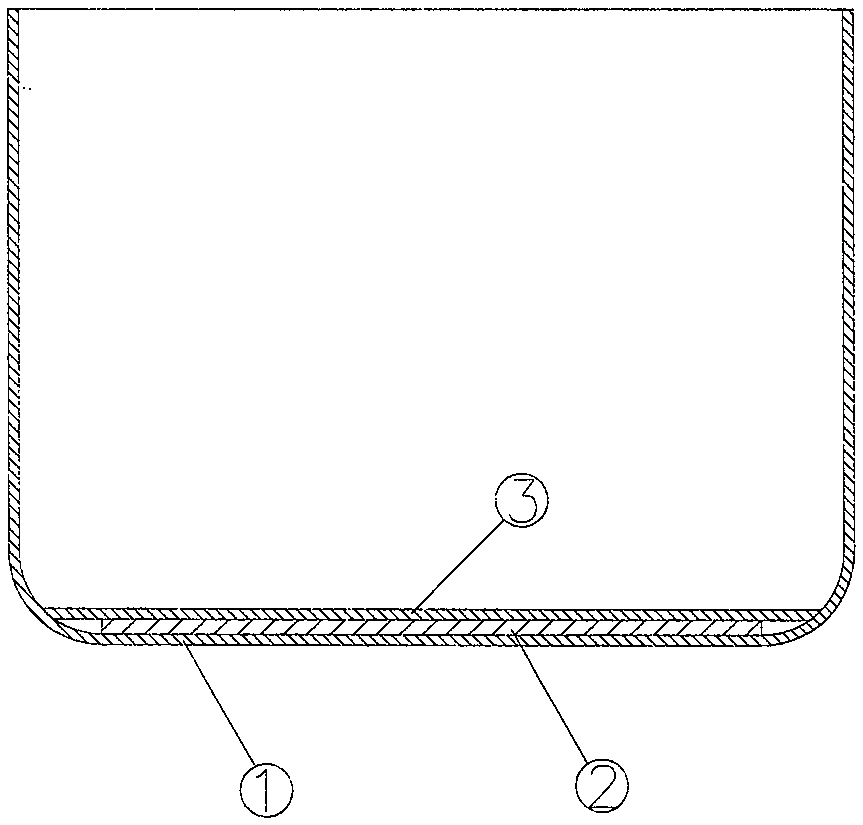

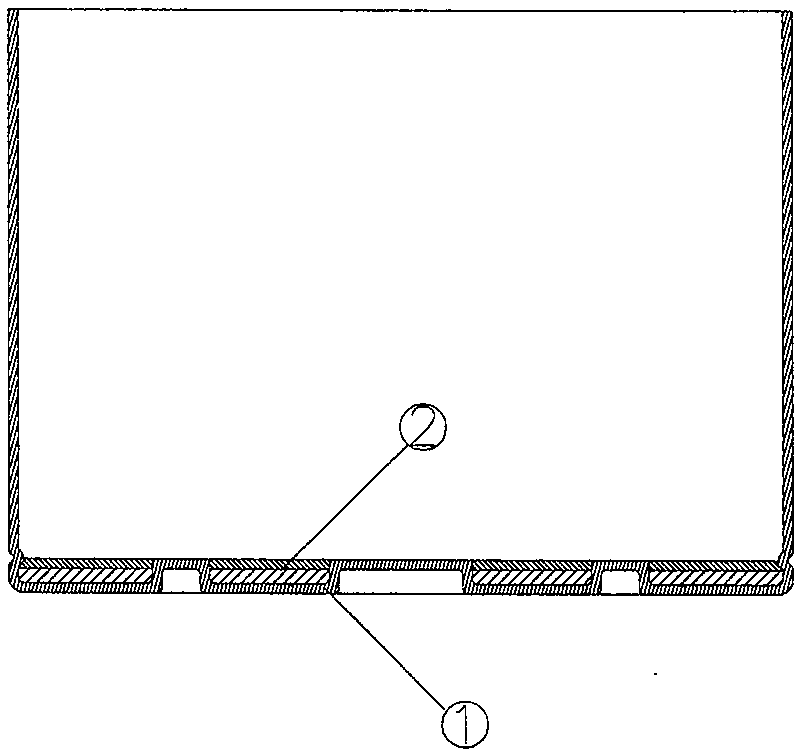

[0011] Option one: in figure 1 The middle pot body ① is made of stainless steel or aluminum, the inner double bottom ② is made of ferromagnetic material, and the inner double bottom ③ is made of stainless steel or aluminum. It is heated to 500°C by high-frequency brazing, and cooled under pressure to combine the pot body and the double bottom. One.

[0012] Option two: in figure 1 The middle pot body ① is made of stainless steel or aluminum, the inner double bottom ② is made of ferromagnetic material, and the inner double bottom ③ is made of stainless steel or aluminum. Resistance welding (contact spot welding, seam welding, projection welding) is used to make the pot body and the double bottom combined into one.

[0013] Option three: in figure 1 The middle pot body ① is made of stainless steel or aluminum, the inner compound bottom ② is made of ferromagnetic material, and the inner compound bottom ③ is made of stainless steel or aluminum material. The compound bottom is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com