Combined vibration-type electric bag dust removal structure

A technology of electric bag dust removal and vibration, which is applied in the direction of combination device, separation of dispersed particles, chemical instruments and methods, etc. It can solve the problems of not being able to meet the use requirements, low resistance of electric dust collector, low dust removal efficiency, etc., and achieve long service life , Diversified dust removal methods, good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

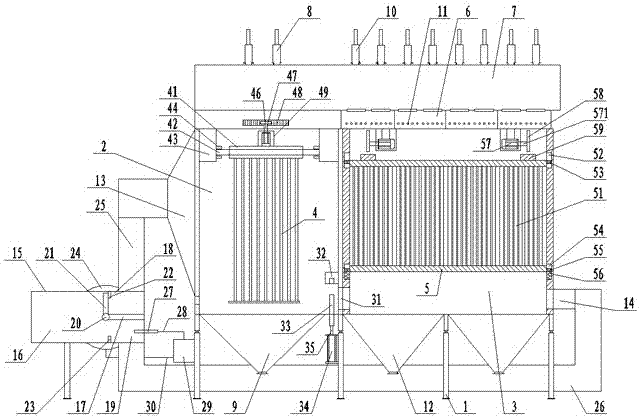

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0009] Such as figure 1 As shown, the combined vibrating electric bag dust removal structure includes: a frame 1, on which an electric dust removal chamber 2 and a bag dust removal chamber 3 are arranged side by side, and an electrode tube 4 is arranged in the electric dust removal chamber 2 , the upper end of the electrode tube 4 is provided with a square outer sleeve 41, the square outer sleeve 41 is slidably arranged on the square inner fixed tube 42, and the two ends of the square inner fixed tube 42 are respectively fixed and arranged on the electrostatic precipitator through the fixing frame 43. On the chamber 2, buffer blocks 44 cooperating with the square outer casing 41 are respectively arranged on the two fixing frames 43, and a lateral vibration servo deceleration motor 45 is arranged on the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com